After a hellishly early start from Birmingham out to Stuttgart and a couple of quick train rides on the ever efficient German train network, I arrived in Ludwigsburg to attend the first couple of days on Altair Engineering‘s European HyperWorks Technology Conference yesterday. For those that aren’t familiar with the company, it has a huge range of simulation products, of which HyperWorks is probably the most well known. Alongside it’s simulation tools (which we’ll talk about tomorrow), it has recently acquired a company that doesn’t initially fit into it’s engineering focus – namely, solidThinking.

solidThinking is a hybrid modelling product that’s been on the market for a good long while and while it’s been well received in Europe but has yet to find it’s feet outside of it’s core market. With a heavy focus towards the creation of complex shapes, solidTHinking offers a range of tools that you’d expect. curve and surface quality are key, but there’s rendering, animation and all the things the industrial and product design community would expect. The solution has also gained much interest over the years because of its dual platform for both Windows and Apple Mac.

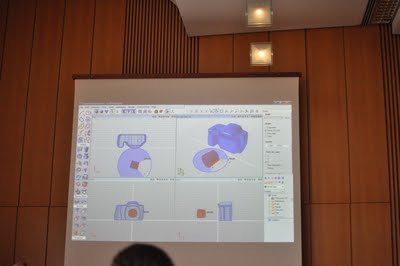

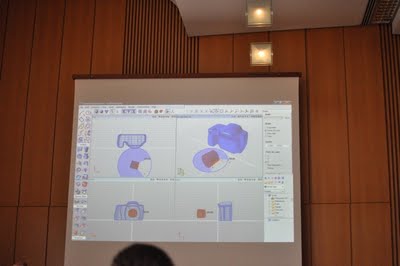

There’s been a huge focus on display quality and visualisation. On the display quality side, both in terms of speed (particularly when using openGL), but also allowing you to use environment maps (very handy for first pass renderings or to evaluate form) and better presentation of entities on screen (driving curves are anti-aliased and presented thicker than isoparms and such – making it easy to manipulate a design). In terms of visualisation, there’s also been a huge concentration on bringing this area up to speed. The 8.0 release introduces not only progressive rendering (a la HyperShot and Modo), but also real-time rendering, where lighting and material changes are instantaneous.

Another focus is the addition of manipulators – for editing geometry position using translation, rotation and scaling using axes and workplaces graphically handles. WHen you’re experimenting with form and position of geometry, it’s key that you’re able to manipulate geometry as you wish, quickly and efficiently. Construction planes are automatically switched, based on your view, which is particularly handy when you’re working in the perspective view – it’ll switch to the most likely plane for sketching geometry, but you can also click the plane and lock it in position. Also there’s some nifty new tools to allow the precise editing of curves, using not only the familiar control points, but also more ad-hoc curve manipulation tools that give you control over tangency, curvature, radius at any selected point, without having to create a heavy curve with additional control points.

But while updates that the team showed today are enhancements, the really big news is the stuff that solidThinking has done for years. The system is history based and retains a record of exactly what operations and features you create, the parameters you set and the tools you use to create complex geometry. There’s been a debate raging on a recent post about Inventor Fusion (link) with a reader questioning why you would want a history tree when working with complex surface forms. In short, seeing solidThinking in action answers those questions. by maintaining a fully featured history, by linking the seemingly simple curve forms you use to create surfaces, then the maintaining an intelligent history of the edits that you make (such as moving control points, pushing and pulling geometry), you have a toolset that’s perfectly linked for creating multiple design iterations, new concepts and new models in a very short space of time.

There’s much talk in the world of 3D CAD about mainstream products supporting the design workflow, but few actually support the work that an industrial or product designer does with traditional tools. The tactile response of pencil and marker sketching, the modelling of Stryofoam, are all still key ingredients during the formative stages of form and function exploration – at the point where product form is fluid and unfixed. solidThinking focuses on giving the user tools that are similar in their flexibility to play with form (in this instance, geometry). Yes, there’s the obvious digitalisation barrier that removes the use from a tactile process such as sketching, but the benefits you can, from using a 3d-based concept modelling tool can give you similar results in terms of output – rapidly generated concepts, ideas and forms. These can be created, played with an worked in a fraction of the time you’d take to do it in a general purpose modelling systems (such as SolidWorks, Solid Edge or Inventor). And the reason you can do that is because you’re using an intelligent modelling system tuned for the process, rather than a generic surface modelling tool.

But enough of my yacking – want a look? Yet another sketchy video showing how the history is used to great effect when carrying out some structural packaging work, where the design of the final features, those that truly challenge any geometry modelling system. What’s interesting is that here, the complex geometry is created first – then the rest falls into place.

There’s more from yesterday shortly.