The new technology can create a 3D image of about one million pixels in less than 8.5 minutes, from 10.5m away

Researchers at the National Institute of Standards and Technology (NIST) have demonstrated a laser-based imaging system that creates high-definition 3D maps of surfaces from as far away as 10.5 meters.

NIST’s 3D mapping system combines a form of laser detection and ranging (LADAR), which is sensitive enough to detect weak reflected light, with the ranging accuracy made possible by frequency combs, as previously demonstrated at NIST.

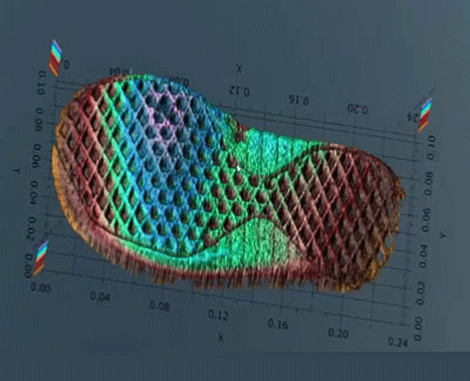

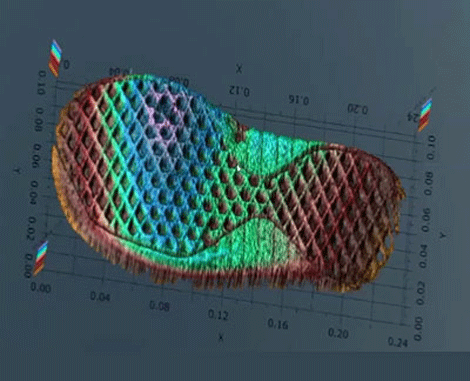

Using a laser of only 9 milliwatts (safe for the eyes at the instrument’s infrared wavelength) NIST’s 3D mapping system scans a target object point by point across a grid, measuring the distance to each point. using the distance data to make a 3D image of about 1 million pixels in less than 8.5 minutes.

Distances to points on a rough surface that reflects light in many directions can be determined to within 10 micrometers in half a millisecond, with an accuracy that is traceable to a frequency standard.

The system has wide dynamic range, enabling precise 3D mapping of targets with varied surface types and reflective properties, demonstrated by the NIST by scanning footprints in soil, vegetation such as cactus (imaging individual spines), and complex mechanical devices such as a piston for a motorcycle.

The frequency comb, a tool for precisely measuring different frequencies of light, is used to continuously calibrate the laser in the imaging system.

The new NIST method offers a unique set of capabilities compared to conventional 3D mapping techniques – similar to optical coherence tomography, but able to operate much farther away from the target and is inherently accurate because of the frequency comb.

By using the frequency comb to continuously calibrate the swept laser, the NIST system can operate much more rapidly, yielding one measurement point every half a millisecond and simultaneously maintain sub-micrometer accuracy traceable to a frequency standard. Finally, the system uses real-time, fast processing digital electronics to produce fully calibrated, 3D megapixel images.

The system is currently about the size of a desktop, so further development is needed, but already a wide range of industries are expressing an interest in the technology.