VISI 21 is set to have an emphasis on intelligent solutions for mould making and stamping die industries

Due for release next month, Vero VISI 21 is set to include over 340 product enhancements and an emphasis on intelligent solutions for mould making and stamping die industries.

There are a host of CAD developments and the next generation of CAM tool paths for VISI machining ready for new complex operations.

We’ve taken had a preview of the new features in VISI 21 and have picked out a few key additions.

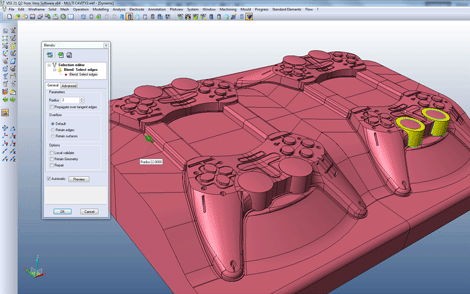

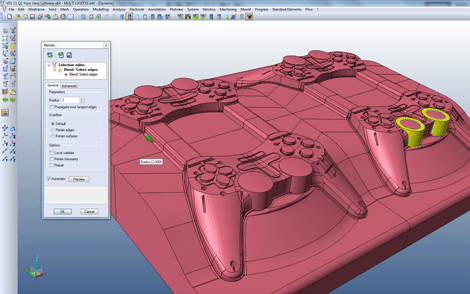

Multi-insert moulds and dies can now be managed with a single ‘master’ part which will automatically update all references of the same geometry

New CAD features include a process for managing multiple instances of the same geometry within an assembly.

For example, multi-insert moulds and dies can now be managed with a single ‘master’ part which will automatically update all references of the same geometry if any part modification is required.

The standard catalogue components will also be managed by the multi-instance technology.

The forthcoming release also includes motion study simulation tools allowing the user to define timelines which control the movement for various groups of components.

The physical interaction of model geometry can be detected and the results of complex mechanisms simulated and investigated – ideal for validating the tool design and checking for potential collisions with slides, cams and lifters.

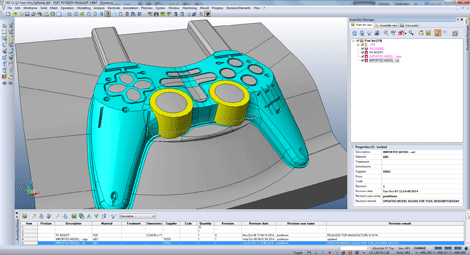

Part Revision Management now makes it possible to manage model changes after they have been released to manufacture: A revision history is automatically created when a model has been released with the model geometry automatically locked.

Any change to a released model will create a copy of the data and update the revision number; providing a history track and ensuring part manufacture is always up to date.

The CAM focus in VISI 21 is immediately noticeable from the new look to the CAM Navigator, command consolidation, and new dialogue boxes are consistent within all milling operations, simplifying toolpath generation.

Feature tree grouping, management of multiple setups/features along with drag and drop capabilities within the tree, making the feature list and navigation more efficient. All features in the tree can be moved, edited, mirrored, and with a new dedicated “undo” mechanism for CAM, while user mistakes can be easily rectified.

Likely to be the big draw, the new CAM toolpaths for VISI machining mean 2D milling operations have been consolidated and include new options.

A new ‘complex feature’ allows the user to define geometry to machine that have a complex side wall and island wall section shape. Typically requiring 3D strategies, the new ‘complex feature’ means that standard 2D operations can be applied.

For simple re-machining on a 2D tool path, the milling operation now bases all the re-machining on the previous operation, meaning all the correct areas are machined, even on the flat areas of the toolpath. Full collision checks on all lead-in and retract movements ensure 2D toolpaths are more efficient.

The GUI layout for 3D milling operations now shares a similar format to that of the 2D CAM toolpaths. For example, the clearance area and oversize settings in the 3D operations will be in the same location as those in 2D operations, and vice versa.

Vero states that the quality of the surface finish is a major point for VISI 21, significantly improving point distribution and enhanced accuracy to this release.

To complement the new 2D and 3D toolpath developments, a new G-code simulator provides users with an accurate virtual representation of the part before committing it to the machine.

The quality and accuracy of the model representation has been improved along with the number of axes that can be simulated. For true NC code checking, an extra option is available to simulate the real posted NC files from the tool path.

Vero adds that all the relevant G-codes, M-codes and moves are simulated against the real machine model to ensure that the NC file run on the machine will be safe.

We’ll be taking a more in-depth look at the software later this year. To see what we thought of the previous version, VISI 20, read our review here.