The big US-based software user conferences are always interesting to attend, but when it comes to sheer size and scale, few beat Autodesk’s annual boondoggle, held in Las Vegas.

Autodesk University (AU) attracts over 10,000 attendees from a huge cross-section of industries. From architects to product designers, from CGI wizards to infrastructure designers, from oil and gas experts

to machinists, they’re all here to see what the software vendor has up its copious sleeves.

But with the crowds to beat, all the sessions to attend and all the big-name keynotes to watch, what were our key takeaways from this year’s event? Here are the ve main messages we took on board.

Autodesk president and CEO Carl Bass opens the proceedings at AU2015

#1 – INDUSTRY CONVERGENCE

This was perhaps the overriding theme of the opening day’s keynotes from both Autodesk CEO Carl Bass and the company’s CTO Jeff Kowalski.

Autodesk’s position as one of the few software providers to address such a broad cross-section of industries arguably gives it a wider view on developments than more specialised vendors.

Both Bass and Kowalski mentioned industry convergence in their presentations, backed up by theories of where things are heading with real-world examples of how and where technologies and use cases are crossing over.

These included an architect working with aviation giant Airbus on generative design components, and a manufacturing customer ConXtech that is using manufacturing and engineering processes to create prefab buildings that can be built at a rate of 10,000 square feet per day.

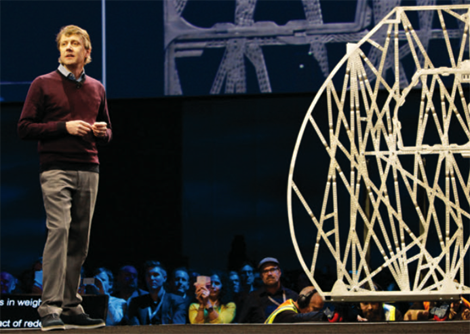

Autodesk CTO Jeff Kowalski shows off Autodesk’s joint project with Airbus

#2 – GENERATIVE DESIGN & AI

A lot of the talk at AU this year focused on generative design. Autodesk has been bullish on this subject for some time, with almost every presentation at the event taking the opportunity to show off the company’s still-in-the-works Project Dreamcatcher.

Most folks assume – as we did – that this is some kind of topology optimisation tool, but a chat with Kowalski now has us thinking that it’s more like a framework for optimisation that allows the user to incorporate all manner of concepts, ideas and algorithms.

One example shown during the keynote sessions once again featured Airbus, this time with its Bionic Partition project. Kowalski showed off how a cross-disciplinary team took a sub-assembly – in this case, a partition wall – from an Airbus A380 and used Dreamcatcher, combined with additive manufacturing, to optimise its form and reduce its weight by 75%.

The resulting part was a skeletal structure, made up of individual cells optimised for speci c loading conditions, that outperformed, both mechanically and structurally, the component previously used.

#3 – GETTING INTO THE IOT

The Internet of Things (IoT) popped up again and again, as it seems to do at almost every software conference on the planet these days.

But rather than just paying lip- service to the IoT, Autodesk has spent money on acquiring SeeControl in order to have, as they say, some serious skin in the game.

SeeControl is a cloud-based o ering that focuses on the more industrial end of the IoT spectrum – a far cry from the consumer-focused, Internet-connected fridge we tend to hear so much about.

Individual cells in the Airbus Bionic Partition

#4 – FULL STEAM AHEAD FOR THE CLOUD

It’s now a good five or six years since Autodesk started its shift to the cloud and it’s showing no signs of slowing down. With customers from almost every industry now sitting up and taking notice, Autodesk University was an opportunity for the company to showcase an area of particular interest to software developers – its partner ecosystem.

Autodesk, after all, can’t supply every niche tool that its broad customer base will want or need to use, so some of the more specialised heavy-lifting will inevitably fall to third-party developers.

At the event, Autodesk launched its new platform-as-a-service (PaaS) offering, Forge, a cloud-based development and runtime environment for specialised third-party apps, along with a $100 million fund to assist the next generation of software developers.

Forge will run on Amazon Web Services’ infrastructure as well as in Autodesk’s own data centres, currently under development. In this way, the cloud will become the go-to venue for third-party developers seeking access to Autodesk’s APIs [application programming interfaces] and SDKs [software development kits].

In keeping with that, over the past five years, Autodesk has been rewriting or creating from scratch componentised ‘web services’ – parcels of code that deliver specialist functions such as 3D rendering and model collaboration – which other applications can call on whenever that functionality is needed.

As a result, developers will be able to hook into Forge and use those components to integrate or build new applications that focus on special market sectors.

That big wedge of money, meanwhile, is there to attract start-ups and pay for development work in key areas that Autodesk intends to fund.

The main focus of this effort, we’re told, will be the manufacturing sector, where Autodesk is as hell-bent as ever on popularising its Fusion product among its competitors’ customers.

#5 WHAT ABOUT THE PRODUCTS?

Autodesk’s event differs from many. There’s no hard sell of existing products. The company probably realises that, to a large extent, that would consitute an act of preaching to the converted and the already-invested.

Instead, the keynotes tend to focus on future directions and trends and on setting forward the company’s vision and interests, in both the near and long term.

That said, some interesting product news did emerge at Autodesk University.

One forthcoming project that sparked our interest involves the changes that Autodesk is making to how its software is sold (as it moves to a subscription- based model) and how that model will be enabled in the coming years.

As it turns out, Project Wingman will be the centralised access point for both software updates as well as licence admin and support engagements — with the goal of running everything through a

single point, rather than continuing with the more disparate licence and support options that Autodesk currently offers as customers reach the outer limits of its product range.

The Fusion 360 team also took the chance to show off some of its partners. Britehub, which runs an online community of certi ed manufacturers, was there to talk about how it enables RFQs and outsourcing (we’ll be talking to CEO Dorian Ferlauto in the next issue), as well as representatives of manufacturing support companies such as 100K Garages, ProtoLabs and MakeTime.

There was, as you’d imagine, also much talk about Project Leopard, which sees Autodesk add a browser-based access route to Fusion 360. It’s very early days, but it’s looking good. Autodesk also showed us some of the updates due for next year in the areas of electronics/PCB design and data management (branching and merging).

Then finally, Microsoft and Autodesk revealed how they have been working together to integrate Fusion with Microsoft’s HoloLens for augmented reality. We weren’t allowed into the demo sessions (at Microsoft’s request, by all accounts), but our contacts tell us that while it was clearly a technology sell, it was also quite mind-blowing in terms of interactivity and display quality. For an idea of what’s planned, take a look at this video:

All our AU2015 coverage can be found online

Read about everything that happened at Autodesk University 2015 for free here

– Day 1 Live Blog – the opening day as it happened

– Day 2 Live Blog – the day as it happened

– Q+A with Autodesk top Brass – we got up close an personal about all the latest Autodesk news

– 5 Things we learned from AU2015 – some of the big stories and our predictions