The CyberGage360 aims to automate the 3D scanning process

US-based CyberOptics is making its latest model, the CyberGage360, available to the European market this winter, promising a metrology-grade, ultra-fast 3D scanning and inspection system.

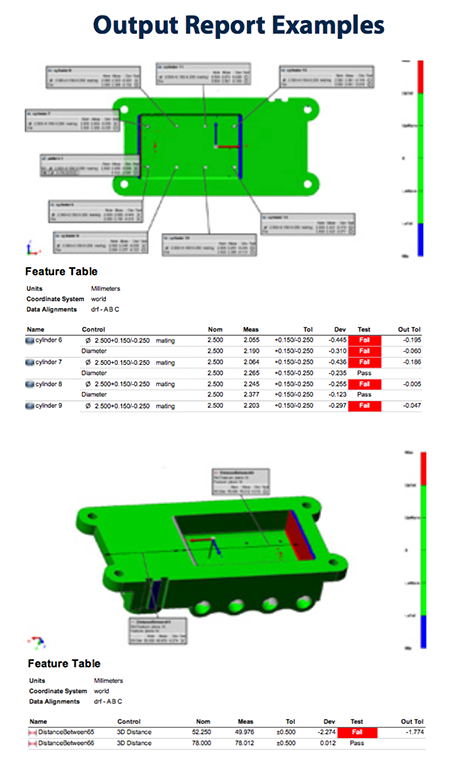

Billed as a single-button process, a precision 360-degree 3D scan of complex parts along with a full 3D inspection report can be generated ‘in less than three minutes’, with little training required.

Incorporating CyberOptics’ proprietary 3D Multi-Reflection Suppression (MRS) technology, the automated single chamber machine looks to bring greater speed and accuracy to the industrial parts inspection and reverse engineering markets.

An example of the types of inspection report that can be generated from the CyberOptics machine from a three minute scan

“We are excited to unveil the CyberGage360 to the European market at Advanced Engineering,” said Sean Langbridge, Global Sales Director, CyberOptics.

“The product facilitates quality assurance by enabling any employee to be an inspector of In-Process QA and Incoming /Outgoing parts whether on the manufacturing floor, in the metrology lab or engineering environment. Customers will benefit greatly from substantial reductions in the development cycle and time-to-market.”