Last month, Al Dean put forward the view that relatively little has changed in 3D design technology over the last two decades. Since then, he’s seen a few new things emerge that could persuade him to change his mind

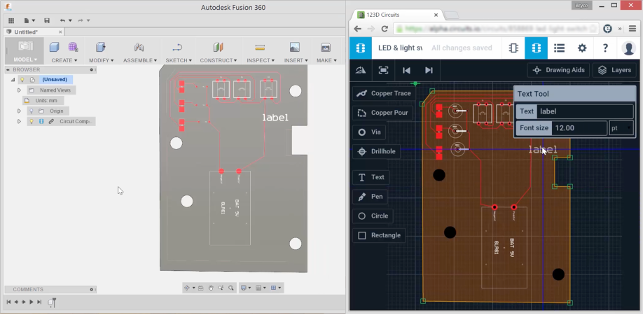

Early demo of 123D Circuits linking data to Fusion 360

As someone who makes his living writing about the field of technology within the context of design and engineering, it’s often an interesting process to put a thought out there that you’re well aware is going to nark a few folks.

You’re likely to get a stream of emails, asking if you’ve lost the plot. You’ll start to question whether you’ll be shunned at the next big industry event. But you might just see a few new things along the way that could make you change your mind.

And so it has proved: in the last month, I’ve been made aware of a few new developments that suggest that, finally, after all these years, there is something new on the horizon for the 3D design and engineering technology world.

One of these came to my attention at Autodesk University. While out in Las Vegas, I got the chance to sit down with the team driving Autodesk’s Fusion 360 product and saw a couple of things that showed where the technology’s heading.

While it’s safe to say that Fusion’s geometry modelling tools are maturing nicely, it’s also clear that geometry and drawings aren’t the limit of Autodesk’s goals for this product.

During the demo, the team showed off just how powerful a cloud-based system can be. They’re currently building out an integration between Fusion and its 123D Circuits service.

If you’ve not come across this before, it’s aimed (mostly) at those working with electronics, with tools designed to quickly prototype a circuit (using a virtual breadboard), then develop those into circuit schematics and eventually, board layouts — including tools to integrate Arduinos and associated code simulation.

The integration between Fusion and 123D Circuits (123d.circuits.io) has been established and is live. If you edit the circuit board, the Fusion model updates and vice versa. If you move components, those changes will be reflected across the same systems.

This might not sound that ground breaking, but the potential is huge. 123D Circuits already has functionality that allows you to essentially switch on, test your circuits and run your code.

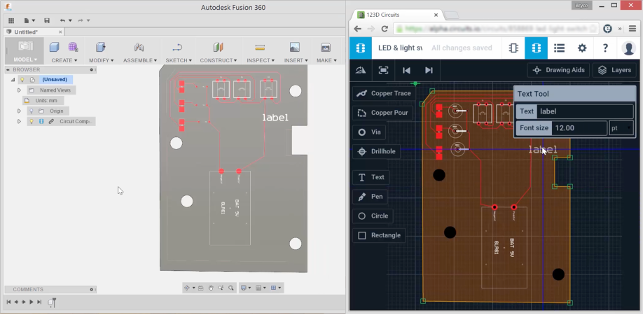

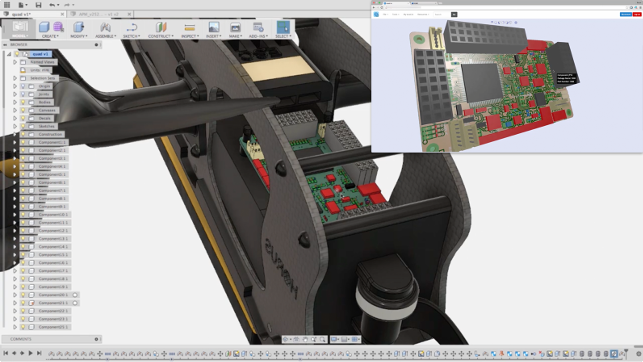

Fusion 360 holding both 2D schematics and 3D PCB models

The next step is to take that same approach and connect it up to the 3D model.

If your circuit tells a servo in the circuit to move 45 degrees, then the mechanical linkage to which it’s connected in Fusion will also move a quarter-turn.

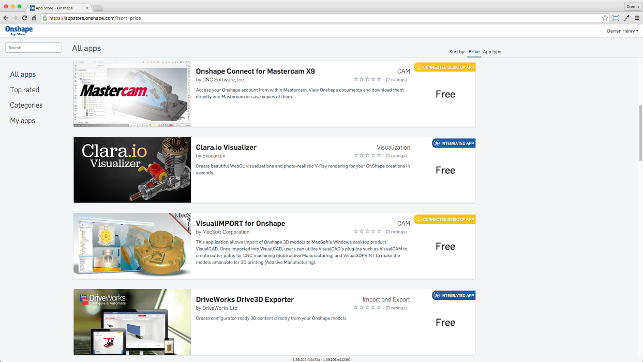

Another interesting development came from Onshape in the last week or so. While the company is now out of beta with its main offering, it’s now also launched an app store (of course, that’s now the default name for anything third-party developer related).

While there are the usual desktop applications that connect to Onshape and read data to carry out their own special purposes, there’s a different class of product on there — one that is similarly cloud-based.

While this isn’t necessarily new, the manner in which you access these products certainly is.

Now, rather than hunting down third-party applications, requesting a trial download, then going through the purchasing process, you simply ‘subscribe’.

Many of these tools are offered according to the same ‘freemium’ model of Onshape, so you’ll get a certain amount of usage for free, then you’ll have to start paying.

But what’s clever here is that, if you do decide to invest, Onshape handles all of the transaction details and your purchase is billed through the same source as your Onshape subscription.

The tools are available in the same browser as Onshape, often directly inside the user interface. Compared to how third-party applications are traditionally sold, this is a shift and a big one at that.

Onshape, as with most cloud-based tools, rolls out each update to every user at the same time. Presumably, those third-party developers using the highest level of integration will be forced to keep up.

Onshape’s fancy new app store, making third-party applications more discoverable

For those of us used to waiting six to 12 months for an add-on to be updated, just so we can update our main system, this will be a massive benefit.

So perhaps all is not lost after all — or maybe I just had a case of the winter blues last month.

As the roles of many designers and engineers are changing, with smaller teams working on more complex products, so too are the toolsets we have at our disposal.

They’re becoming more powerful in terms of task coverage as well as the ability to, if not carry out additional tasks, then certainly to interact with other tools engaged in the same process.

Alongside this, the process through which we acquire the additional tools we need to carry out our work is shifting, both in how the tools are adopted and used.

Anything that removes time and effort from that process will be a welcome development for many, I’m sure.

Electrical tools and App Stores catch our eye as the Cloud brings change

Default