An EBM seatpost part (printed by Addaero Manufacturing) as its support structures are removed-Credit: Spencer Wright

Around two years ago, curious about how the next generation of aerospace parts was being made, I began researching metals 3D printing. I’d moved to New York recently, and at the time MakerBot and Shapeways were really humming.

Distributed manufacturing and generative design were in the air, and I was fresh with ideas from my time managing a small robotics development shop. I was intrigued.

My interest is in engineered, mechanical products. I’ve used SLS and FDM for prototypes and tools, but I wanted to find uses for 3D printing metals that resulted in commercial products – things that people actually go out and buy.

I also wanted to test whether 3D printing could really make distributed manufacturing possible – and how much design freedom it really offered. So after a few bike rides spent thinking about applications that might work, I spent a weekend designing a titanium seatmast topper.

As potential markets for metals 3D printing go, high-end road cycling is an excellent candidate. Reductions in weight and wind resistance are incredibly valuable. Custom, bespoke designs are highly prized. Sales cycles are relatively short, making just-in-time production attractive, and demand in the high-end market tends to be price-inelastic.

Just as important, though, was the fact that cycling is something that engineers across industries tend to have some fondness for. As I began my research, I found people eager to apply their industrial knowledge to something more human-scale, and that shared interest gave me a leg up in understanding the capabilities and constraints of the technology.

So: how could I design a product that took advantage of what additive manufacturing had to offer?

Procurement

Throughout my career, I’ve relied on close relationships with suppliers to make sure that I’m aiming in the right direction.

When I began looking at metals 3D printing in earnest, I used the same strategy that I’ve used in the past: searching out any information I could on the technology; modelling up an initial design; calling job shops to get feedback, advice and cost stimates.

DMLS seatmast topper (printed by Layerwise/3D Systems) assembled and ready for testing-Credit: Spencer Wright

But here arose the first problem: Unlike conventional manufacturing, metal AM has a relatively small install base.

I started my work not too long after GE acquired Morris Technologies, leaving an immediate hole in the supply chain for 3D printed aerospace parts. The number of companies offering metal 3D printing services in the US was only a few dozen, with many specialising in one particular industry.

But more problematic than access to parts (or even a competitively priced market) was access to information.

Metal AM has only penetrated a few industries and, within those industries, a few key clients dominate overall production capacity.

Expertise is clustered in pockets, and remarkably little of it exists in the public domain.

The metal 3D printing machine manufacturers are old school. They have close relationships with big OEMs, but often aren’t connected to the end use customers pushing the technology forward. And when they do have time to develop application guidelines, they’re often distributed privately in PowerPoints – leaving very little useful information in public.

On the other hand, job shops usually don’t have the capacity to do real customer development themselves. Most of them are tied up with a handful of big clients, and it can be very difficult for them to put much effort into building inroads into new industries and markets.

More broadly, almost nobody in the industrial 3D printing industry is good about working in public. Very few end users, job shops, or machine manufacturers have blogs or Twitter accounts, and when I started my research the Wikipedia entry for DMLS was only a few sentences long.

Talking to the job shops was frustrating early on. Some told me flippantly that my part would be no big deal at all. Others said that it really wasn’t a suitable design for additive.

Many shops only print in a handful of materials (it’s expensive to switch materials on powder bed fusion machines), and so we’d have speculative conversations about what the cost would be once they got titanium running.

Worst of all, the design feedback I got was generally vague. Most job shops have dedicated sales staff, many of whom are engineers by training, but they generally aren’t using the equipment on a regular basis and therefore aren’t really able to – or interested in – talking about the pros and cons of one design or another.

But the more I learned about the industry – and the more I shared what I was learning on my blog – the more engineers reached out to me, interested in what I was doing.

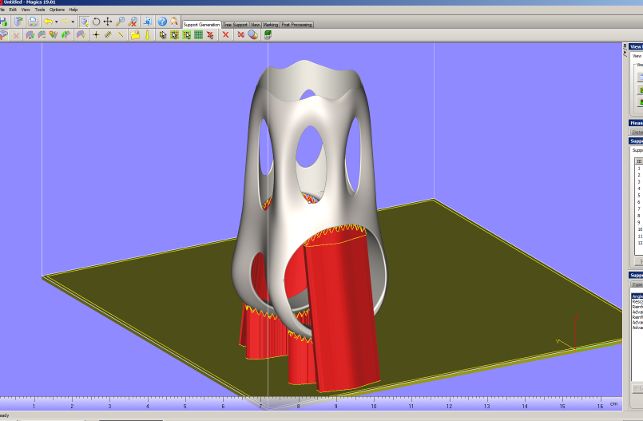

Temporary lattice structures are added in order to ensure a successful print-Credit: Layerwise/3D Systems

While the corporate centres of the aerospace, medical and other industries working in metals 3D printing tend to be secretive, I’ve found application and manufacturing engineers at those same companies to be both interested and excited to share their expertise with someone on the fringes. Many of them outwardly expressed frustration with the industry’s level of secrecy.

Manufacturing

Throughout my journey, I’ve tried to remain technology-agnostic.

In general, I’ve focused on two processes, both of which fall under the umbrella of Metal Powder Bed Fusion. Because it has a much higher install base in the US, my early experiments were all with laser-based machines. (You’ll often hear this referred to as ‘DMLS’, though technically that’s a trade name.)

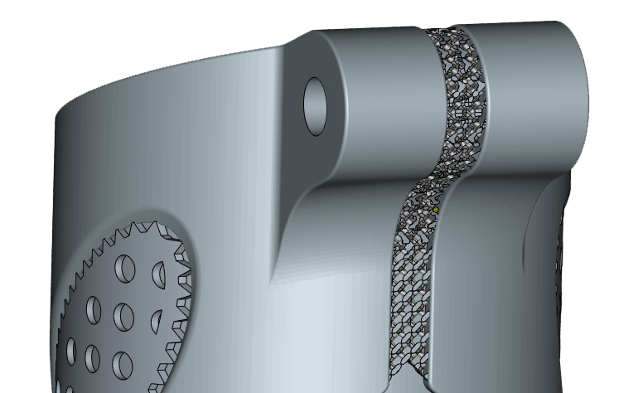

Support structures are added in Materialise Magics SG+ Credit: Spencer Wright

More recently I’ve experimented with Electron Beam Melting (EBM). With each part that I’ve printed, my aim has been to achieve a better understanding of a specific aspect of the technology.

In the beginning, I focused on learning the constraints of building thin-walled structures (spoiler: they’re significant).

Then I worked to validate whether metals 3D printing could indeed be used to make a functional part (spoiler: it can).

Now, I’m pursuing two parallel paths. On the one hand, I’m working with some of the most advanced design software in the world to try to create truly optimised designs. On the other, I’m going through the practical exercise of optimising my manufacturing processes to meet the needs of my customers.

Throughout the process, I’ve had incredible help from Dustin Lindley at the University of Cincinnati Research Institute; Dave Bartosik at DRT Medical-Morris; Martijn Vanloffelt and Tom DeBruyne at Layerwise; Marcus Schroeder at EFBE; and the whole team (Rich, Dave, and Cesar) at Addaero.

All of these people have a genuine interest in using their knowledge and expertise to help my product development process while also spreading more awareness of the technology in the wider world.

The fact of the matter is that metal AM is still a technology in its infancy. Despite the incredible advances that DMLS and EBM have made in the past five years – and the shocking pace of growth in the industry over that same timespan – they’re still very much in the R&D stage.

And given my original curiosity in distributed manufacturing and truly innovative design, I feel strongly that it’s in everyone’s interest to get metals 3D printing to the point where it’s a stable, predictable process.

The part straight off the machine, with support structures in place-Credit: Spencer Wright

As a result, I’ve been careful to share as much as I can about what my manufacturing partners and I think about both the process and the product at hand. The more people who know how the industry works, the healthier the market for metals 3D printed products will be.

Ultimately, sharing my own experience will only speed up my efforts.

Findings

At this point in my own process, I’ve validated a number of basic points: first, that it’s possible to print functional bike parts; second, that at least a certain set of customers find 3D printed bike parts appealing; third, that the cost structure of those parts is at least close to what it needs to be to create a self-sustaining business.

On the manufacturing side, I’ve learned a lot about the limitations of DMLS and EBM, in particular with respect to building thin-walled structures with mechanical features.

I’ve also spent a bit of time working with design optimisation (topology and shape) software, and navigating the convoluted software tool chain from NURBS, to optimisation, to build prep.

Many of the details I’ve learned are recounted on my blog, but suffice to say that the current workflow is disjointed, inefficient and you don’t always get a usable design at the end of it. I’ve also learned something about what expertise in metals 3D printing really means.

Female threads like the one in a seatmast topper can’t be printed, and need to be cut once printing is complete-Credit: Spencer Wright

Working with a nascent technology can be frustrating and expensive. But with the right guidance, a collaborative mindset and enough elbow grease, it’s possible to make meaningful progress in a matter of months.

Of course, there are significant barriers. Learning the design for manufacturing process really requires access to a metal 3D printing machine, and even then it’s a process of trial and error. And without an understanding of how a part is being modified in order to print successfully, it’s nearly impossible to improve upon the underlying design.

Additionally, the industry is constantly shifting – so any knowledge you acquire today may be out of date in six months’ time.

That said, I’m excited for the future of the technology. And in the coming months, I’ll be working hard on developing my parts further – and pushing the industry as a whole forward, too.

Spencer Wright is a designer, operations strategist, and blogger working on a big new venture in New York City

pencerw.com/gemba

Spencer Wright on his adventures in 3D printing with metals

Default