Z Corporation has received quite a bit of press recently with the launch of its two affordable entry-level printers – the monochrome ZPrinter 150 (£10,900) and ‘multicolour’ ZPrinter 250 (£17,900).

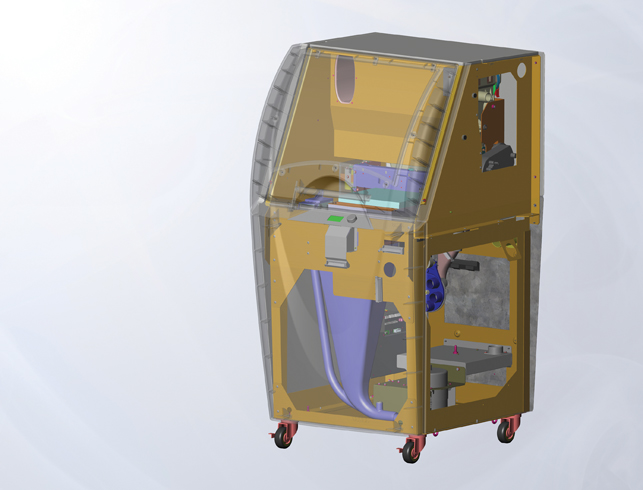

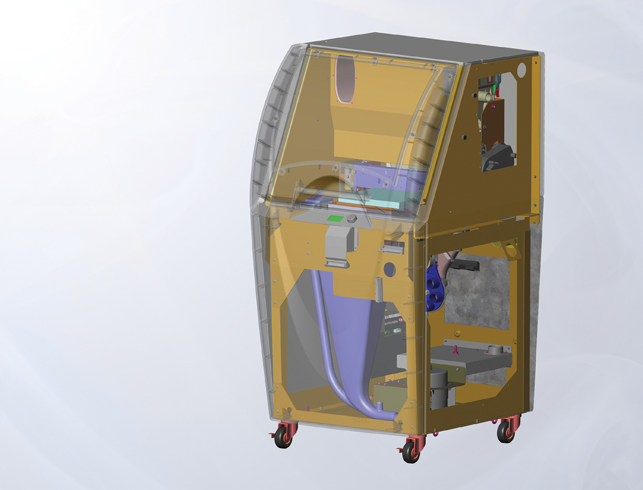

The Z Printer 150 and 250 were modelled in SolidWorks

With a small physical footprint, allowing them to be easily incorporated in the home, classroom, design studio or small business, the machines have a build envelope of 236 x 185 x 127mm, a build speed of 20mm/hour and resolution of 300x 450dpi. But how did Z Corp manage to design and engineer a product at such a price point that still offered a reasonably full set of features?

Well, according to Joe Titlow, vice president of product management, it is something that Z Corp has been looking at for over ten years. “We have long had the product strategy of wanting to get 3D printing to ultimately be more accessible for every student, designer, architect and engineer out there and, of course, a big part of that is bringing down the cost of the systems themselves,” he says.

Titlow is responsible for product strategy and defining what new products will be worked on next at Z Corp. He works very closely with the research and development department, which consists of about 35 people, who work on 90% of its products with the other 10% coming from consultancies who may help in the areas of industrial design or software development. As Titlow explains, the initial strategy for these new printers was to create a fully featured product but offer it in a smaller, lower cost machine.

“There are low cost systems in the marketplace, but they are not necessarily fully-featured, polished products. Additionally, they are not particularly cost-effective to operate, are often not easy-to-use and most do not offer many of the benefits of the mid-range systems,” explains Titlow.

So, with the goal in mind of creating a lower cost product that still offered many of the features of its mid-range ZPrinter 450, the development team started off the process with a blank sheet of paper (well, in this case, a whiteboard) and began brainstorming ways of how to reach this goal.

From these brainstorming sessions the team essentially came up with three routes it could go down that would allow Z Corp to hit its internal cost target.

Firstly, the machines could be designed from the ground up. Secondly, after looking at its mid-range machines, the team considered how much cost could be taken out whilst still maintaining the required features and functionality. Or, thirdly, it could create a hybrid machine of the first two options. The more it was discussed the more that the second option began to emerge as the more favourable route. It would mean being able to leverage a lot of the assets and design work the company already had, as Titlow explains.

“It was a competition between that approach and basically starting over, building on everything we knew. We debated that pretty seriously at the beginning as to which way to go. But ultimately, the direction we ended up going was trying to pull the cost out of the system we already had,” he says. “We had the feature set that we wanted for the low end product already in existence on our mid-range machines. The real challenge was getting that feature set in at a lower cost to the customer. Doing that you have to tackle new problems.”

Driving down costs

The next stage was a cost analysis looking at the price of every single component and really trying to uncover any hidden costs as well. “We really dug deep to get a full understanding of where all the costs are to deliver the particular product and then we set about brainstorming how to pull those costs out,” says Titlow. So, for instance the team looked at driving down the price of the really expensive components but also seeing where just a few dollars could be saved here and there.

“The idea at that point was to brainstorm, develop a huge list of ideas – some of them are pretty crazy and some were kind of slam dunks that left us thinking ‘why didn’t we just do this the first time’ and everything in between,” he adds.

Problem solving

One of the ideas that emerged from these brainstorming sessions was that because the vacuum blower motor within the internal vacuum system of the ZPrinter 450 is a very expensive component, a lower cost vacuum system could be considered. “We did an analysis and we looked at everything that was available and we settled on a vacuum system that basically was a little bit lower performance but we were comfortable that it would fit all our design requirements,” says Titlow.

However, once Z Corp had built this full system and started testing it they realised that there was a collateral impact that hadn’t been predicted at the start.

This ultimately created a problem that needed to be solved. “In this case it was the emptying of a particular internal hopper system. In certain conditions it wouldn’t empty fully because it didn’t have the vacuum power that the more expensive vacuum did.

What we did then was develop a new duck bill valve, which is basically a little valve that when attached to that part of the system would allow the proper airflow.

This enabled the powder to empty from this particular component,” explains Titlow. “So, we started with the basic idea of reducing cost but ended up with a collateral impact where we needed to be more innovative to solve the problem.”

Even though the development team were borrowing a lot of the features and components from existing products, this was ultimately a totally new machine so it still had to create a whole new CAD model in SolidWorks. Then when it came for prototyping the 3D models there wasn’t a problem as it had a multitude of machines at its disposal in-house due to the nature of Z Corp’s business.

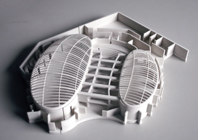

“We are very lucky and fortunate in the fact that we have access to a number of 3D printers internally and, talking of low cost, when we are using them internally they are essentially free so we use them a tremendous amount – any chance we get,” says Titlow.

“Traditionally, we do most of our model building when we are trying to really be innovative and invent something new. We’ll print hundreds and hundreds of models trying to solve new problems. That is where they are great but even in a project like this where it may be a little bit more straightforward in terms of engineering, having a model available is really valuable.”

Fast track

In a project of this nature where the budget is pretty tight, speed is highly valued, so the full development process was just nine months.

“Deciding to not go the route of a huge development team and spend millions of dollars in tooling – we tried to go the quick and low cost method for development and that meant that we wanted to move very quickly,” says Titlow.

Like all projects, although injection moulding and metal forming is contracted out, final assembly is done at Z Corp’s factory in Burlington.

Since the ZPrinter 150 and 250 were launched in July, the feedback has been favourable and justifies the company’s decision to go down the route it chose in the development process.

“We are pretty confident that we have the right strategy here and that a low cost system, even though it is low cost, still needs to be pretty fully featured. You are going to have a customer that really wants an easy-to-use system and so including all of the features around that at the entry level has resonated very well with the people looking at this market,” claims Titlow.

www.zcorp.com

Tanya Weaver talks to the man behind the development of Z Corp’s latest 3D Printer