Since 2012, Phil Hall has integrated 3D printing as part of the Design and Technology (D&T) curriculum at The Windsor Boys’ School, a UK-based school for boys between the ages of 13 and 19 years old, where he has taught for the past 17 years.

He believes that the use of this technology will be instrumental in many industries in the future and, as such, students who take D&T should be using it in their projects in a similar way to how it’s been used in industry. Not, as he says, to print off Yoda heads downloaded from Thingiverse as that has arguably very little educational value.

His work in this area has been recognised through a number of awards including the ‘Outstanding Teacher of Design and Technology Award’ which he received from The Design and Technology Association (DATA) earlier this year as part of its annual D&T Association Excellence Awards. His students’ work has been featured on a number of different D&T websites as exemplary examples of what can be achieved and will also appear in forthcoming textbooks for the new examination specifications for the subject.

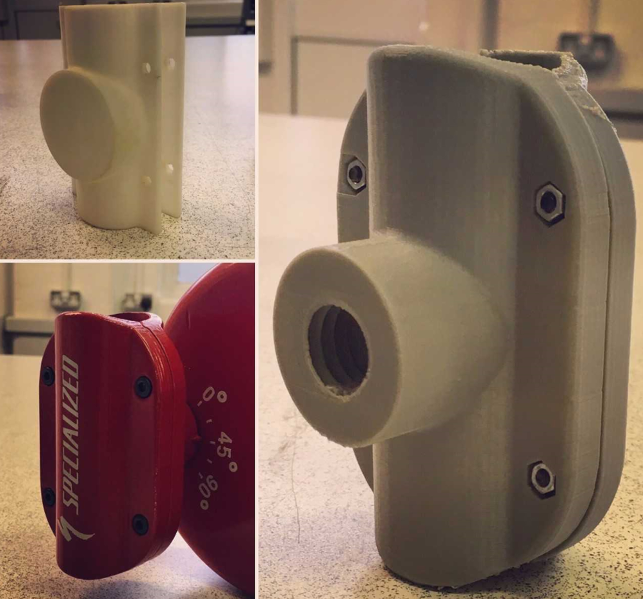

Iterations of a bracket system for a laptop to bike carrying unit

D3D: Why are you such an advocate of 3D printing in education and what set you down this path?

PH: I strongly believe that D&T is a progressive subject. The clue is in the title – Design & Technology – and that, as educators, we should be doing everything we can to prepare students for their careers outside of the classroom. If they choose to pursue a career in design or engineering then they will be heavily involved in using CAD and additive manufacturing.

I also believe that we should be enabling students to achieve the best possible outcomes. 3D printing allows them to push the boundaries with their design tasks and achieve outcomes which, through traditional workshop methods, would not be achievable.

Some advocates of traditional manufacturing methods will argue that this is wrong and that pupils need to be taught craft skills. I would say that we are merely developing skills in students in a different area of the design process – ones which potentially have more ‘real world’ applications.

We began 3D printing about five years ago after successfully ‘bidding’ for a 3D printer under a scheme run by The Department for Education, designed to get more schools 3D printing. Only 20 printers were made available; staggering considering that the Chinese Government is placing 500,000 printers into their education system!

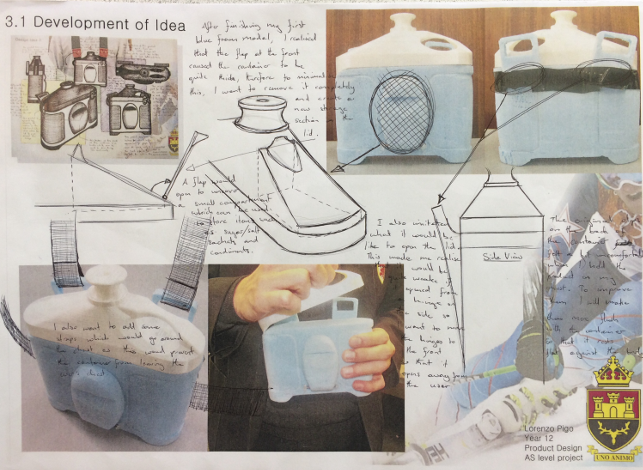

The Herb Garden Project

D3D: What 3D printers do you have in your classroom and what CAD software do the students use to create their 3D prints?

PH: We have three Makerbot Replicator printers. All of our printers are second hand/refurbished and were bought by the Parent Teacher Association (PTA) after we realised that we’d need more in order to meet the demand for prints being made by the students.

I find the Makerbot printer to be wholly reliable and this is really important in education. For three to four months of the year the printers are running around the clock. The other great thing about the Makerbots is that they are pretty simple and straight forward to fix when something goes wrong, as it invariably does.

Build size was another important factor, although, as students become more aware of how products are manufactured, they tend to part model and assemble just as it would be done in industry.

Over the past few years I have received several other types of printer to trial. The Makerbot is, at the moment, for me, still the best one in that it stands up to the rigours of use in education.

We use Autodesk Inventor to create the models which we print. Again, keeping things to industry standard is important, so teaching the pupils how to navigate this software really helps. When the pupils arrive in Year 9 (13 years old) they are tutored in a CAD module for six weeks. This teaches them the basics and allows them to start their 3D printing journey.

Most pupils see the potential of this software and continue to learn it in their own time. One of the great things with Autodesk is that the pupils get to download the software for home use. This really helps.

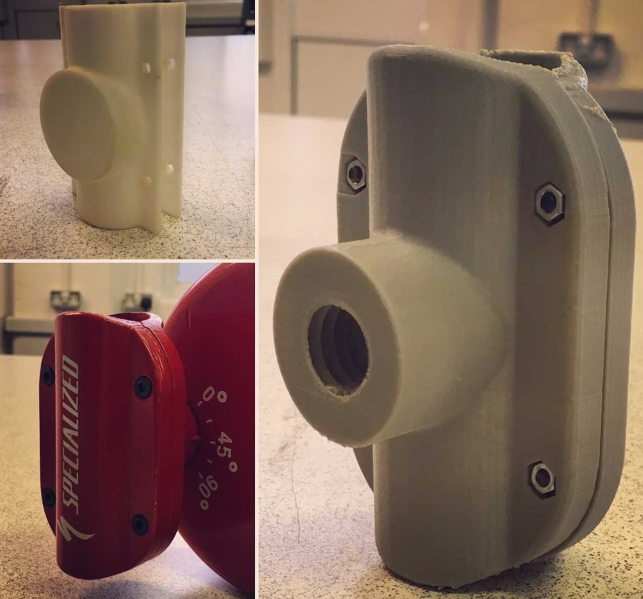

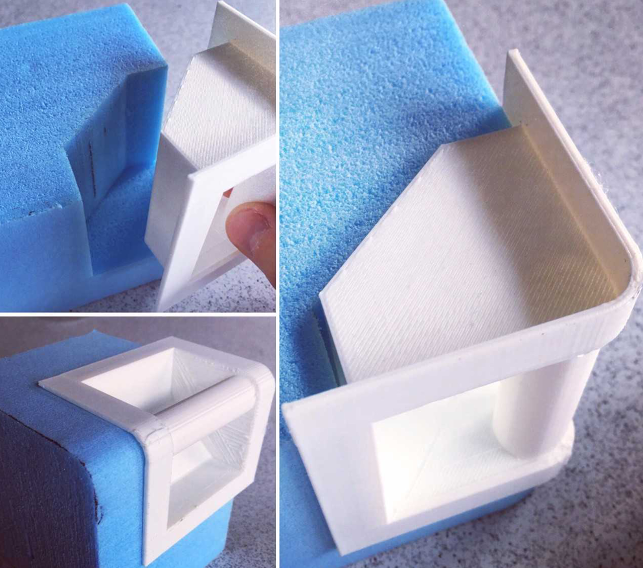

Iterations of a portable speaker/storage unit showing blue foam modelling through to final 3D printed model

D3D: If they are taught CAD in Year 9 when do they start using the 3D printers?

PH: Printing really begins for our pupils in the GCSE years. In year 10 the pupils will use 3D printing in the development of their products (small component parts such as clips, handles, brackets etc.) to help with the iterative process of modelling, testing and evaluating.

Printing saves us material and time and really allows the pupils to learn a lot about their projects. In the final year of the GCSE, pupils will make more use of printing and produce larger parts for their final presentation model.

This year we have been working more on combining 3D print parts with natural materials and it has worked really well.

A-level students will go through the same process but produce more iterations than the GCSE pupils and more complex parts.

Lid prototype for a flask unit for skiers

D3D: But how can schools invest in 3D printing when we keep hearing about funding cuts?

PH: This is a political issue. Funding in education in general has been cut to the point where many schools are now asking parents for contributions for their children’s educations!

Along with the lack of funding, D&T is also suffering as it has been marginalised since the Government has introduced the English Baccalaureate, which doesn’t leave enough room for creative or vocational subjects. This leads to fewer pupils opting for D&T and schools start to consider whether or not offering the subject is a viable option.

Sadly, some have cut it altogether which is a travesty and an unmitigated disaster for the creativity so brilliantly demonstrated by many who work in the creative, engineering and STEM [science, technology, engineering and mathematics] related fields.

D3D: In which case, would you encourage more companies to get involved?

PH: Education NEEDS more companies to get involved – either donate a printer to a local school or gift free filament for the pupils’ projects. Money is obviously the stumbling block with getting printing into schools. More schools would love to get on board but because budgets are so tight it isn’t a priority right now in education.

We need a major player in the 3D printing industry to invest, otherwise there will just be handfuls of schools doing great things and everyone else will still be looking on.

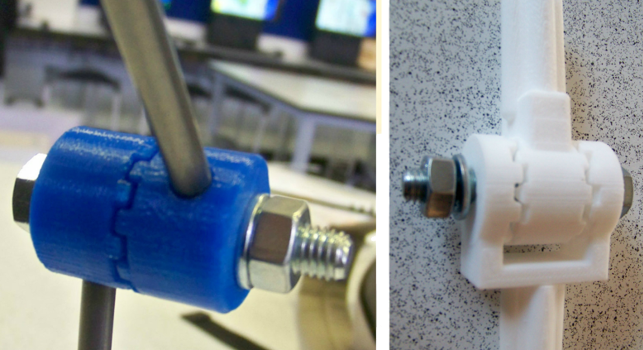

Iterations of a bracket to be used on an angle poise lamp

D3D: It’s all well and good having these 3D printers but teachers have to take the time to learn how to use the technology, and time doesn’t seem to be something they have a lot of.

PH: I agree that as a teacher my time is consumed by lots of things and the thought of another time consuming thing for me to do would have me running for the hills.

What D&T teachers need to do is see the bigger picture and how this technology can increase engagement, enthusiasm, quality and understanding for pupils in their subject as well as raising attainment and, in the long run, actually save them time. When I began my 3D printing journey I was so excited about what it could do for my pupils – and me as a professional – that I made the time to learn.

Unfortunately, not all share the same passion. I have offered my time and resources free of charge to local schools in order to get them started and had no uptake. If teachers themselves don’t buy in then this technology will never get off the ground in education.

D3D: Have you heard back from any past students about how your teaching of 3D printing has stood them in good stead in their further education or careers?

PH: As we have really only been teaching this technology for around five years it is difficult to gauge its impact on students’ future careers. Most of the ‘first wave’ of students who were involved with the first 3D printer are still in university.

The only real positive feedback we get is when our students go to interview for university places and take their folios with evidence of what they have been doing. Much of the feedback is amazing, in that they are told that their work is way ahead of where they would be when starting at university. We also have ex-pupils at university who come back or send work to be printed, which we are more than happy to do.

Prototype for a corner ‘grab handle’ for a portable speaker

D3D: Being as passionate about 3D printing in education as you are, what is the key message that you’d like to get across?

PH: My key message is that 3D printing is an excellent tool by which to teach the manufacturing process to young designers. The barriers that stand in its way are very difficult to break down – a curriculum set against creativity, a new subject specification still stuck in the past, budget constraints, teachers who aren’t trained to deliver this technology, limited links with industry including printer manufacturers, etc.

We have proved that it is possible to make a massive difference with this technology but you have to be brave enough to step outside of your comfort zone and be in a school insightful enough to support it and invest in it.

On why he is championing the use of 3D printing in education

Default