Al Dean: Can you give us a little background to how Gordon Murray Design came into existence?

Gordon Murray: Gordon Murray Design is largely made up of my old design team from McLaren Cars, which I started about 10 to 15 years ago to create the McLaren F1 Road Car and to do the SLR for Mercedes Benz. Basically, the team is the same, transplanted into this building, under a new name. We’ve got over 400 man-years in the automotive industry, and have about 1,800 man-years working together. We’ve done many car programs together and this is our 5th whole car program. This is key, the whole company is about whole car programs, no other jobs and no consultancy at all.

Gordon Murray Design’s Wharfside facility in Shalford, Surrey

AD: How did you move from ultra high performance motoring to working on something so completely different?

GM: In 1993, I started looking at the congestion problem. It wasn’t emissions in those days, because people weren’t really aware of it, but staring around me, sitting on the A3 looking at everybody sitting in huge cars, thinking “this is pretty unsustainable.”

All my life I’ve done high performance and racing cars, so decided to do something about it and came up with a concept for a car to solve the problems. I’ve been cobbling away at this from ‘93 to ‘99, when in ‘99 we actually did a year of work at McLaren on the car, just to prove the concept. Basically I’ve just transferred the intellectual property from McLaren to here.

AD: Tell us a little more about the Type 25. How is the car shaping up and what exactly are you looking to achieve?

GM: The car is made in a completely different way that’s going to turn the automotive world on its head. The production facility required is only something like 20% of the floor area traditionally needed and something close to 25% of the investment to produce 100,000 cars a year. It’s a very low cost car, costing around 5,500 quid, very green and vastly lower emissions than the average UK car and all on petrol – it’s all designed with lightweight materials and a lightweight architecture.

AD: Starting again from scratch, but with a very skilled and knowledgable team, must give you a huge head start. Creating a brand new vehicle from the floor upwards must be a fascinating but challenging thing to do. What does your process look like and at what points are you introducing technology into the mix to assist with the process?

Gordon Murray at the Wharfside facility

GM: The last job we all did together was a complete turnkey; we design developed, prototyped, developed and manufactured the Mercedes SLR. The design process was done entirely using CAD using Catia V4. We’re onto Catia V5 now.

That throws up all sorts of questions in the design process, when you’re trying to get from the screen to the real car. Most of those problems are to do with everybody working on a flat screen. It’s not full size, so everything is small.

Even through you can zoom in and out trying to design a motorcar on a screen is pretty near impossible. Then when you get things wrong and things clash, you don’t have a chance in hell of finding them.

In addition to that, we need greater communication in the team, but not have a group of individuals standing around a screen, whereas the old way, you had a full size car on a drawing board and the car was there everyday for people to see.

The McLaren F1 was probably the last car worldwide to be designed by hand on a drawing board and the communication was fantastic because everyone could come in and stand around the board and inspect the car. We had a meeting every Monday morning and had the entire team standing in front of the board, and talking about the work we did last week and for the week ahead – that’s how we’ve always run companies, focussing on communication.

The end result of doing the F1 by hand was we had one clash on the car, whereas typically on a car program you can have thousands to fix.

So, when the design team arrived here I asked, “Do we really want to play this game or can we think of a new process that involves some other tools that can makes this more full size, more three dimensional, and get the communication skills back in?

The guys came up with this ingenious design process, which could be sold if we could bottle it. We’ve reinvented the drawing board with a mixture of CAD and some other technologies. The automotive gold standard is Catia, and we have to produce everything in Catia for Tier One and Two suppliers. So we knew CAD.

We also have HP as a technical partner and this wouldn’t have been possible without having them on board, because they have a new generation of high speed printers which allow you to print a full size print of a car in about ten minutes, whereas before on the SLR project, a print off would have taken a day, so it would be out of date by the time it was finished. So, we have this process where we integrate CAD and a full-scale print out every week, so we still have the communication based on that.

The other thing that is interesting is that we’re doing much more three-dimensional work to back that full size 2D print. We want to buck the automotive trend to put everything out to agencies. They put styling, aerodynamics, and prototyping out. We’ve actually brought all that back in house.

From performance car to eco car – Gordon Murray Design’s Type 25 promises to be one of the most economical, environmentally friendly and affordable city cars ever produced. Image copyright Gordon Murray Design Limited 2007

AD: You recently acquired a Stratasys machine. How is that working out and what benefits are you seeing by having that technology in-house?

GM: The prototype workshop is fully equipped, so we can design a car in the design office and spit a running car out of the double doors at the end of the office and we can do everything in house. And the 3D aspects of that are again multi-fold.

We have a full size CNC 5-axis machine so we can machine our own full size mould and patterns for the car, we have a traditional wooden pattern shop as we still do a tremendous amount of mock ups and things in wood and the third and most important element is the Stratasys machine because we use it in several different ways that add to the design process.

It’s more of a design tool and we actually make parts, but it will come into its own when we come to make the final components. One of the reasons we chose that particular machine, is that we can build structural components so instead of going out to an agency to do the first dashboard, IP panel, or all the mirrors, we can do it all in house.

That’s definitely one use, but we use it much more as a design tool. A really good example we did last month is that the car is very unconventional in its architecture shape and layout. You don’t get in and out like a normal car – a child seat isn’t loaded like a normal car.

AD: So, they’re easier to get in?

GM: Yes, they’re very easy to get in. You don’t have to bend your back – I’ve watched people struggling to get people into cars for too long. Things are in different places on the car because it’s unconventional. The fuel filler was one of those things. On how many cars can you only fill from one side? You can do all the CAD design on a screen but you can’t assess how comfortable it is to open the fuel flap and get the nozzle in.

We designed an unconventional fuel filling system. The guys designed and rapid prototyped it overnight, bolted it onto the mock-up, got a real fuel nozzle and got people to come in and try. Now, that’s a design tool. That’s not making prototype parts; that’s a real, usable design tool.

The other area is that parts of the chassis are tubular, so you get areas where one tube meets another with very odd shapes and the prototyping guys have to generate that geometry. You can generate all the CAD drawings on the planet, but you’ve still got to make the geometry where one tube fits another. So our guys came up with an ingenious thing where they inverted the CAD information and they rapid-prototyped an external sleeve where you slide it onto the tube and you scribe around the tube and the guy cuts the tube – and the parts fit together. So that’s another design tool. The machine is so versatile it’s actually driving us to think of new ways of using it. That’s a really good example of where it fits.

The Gordon Murray design team

In a more conventional automotive company, we would buy a machine for making prove out components and working prototypes, but we’re using it for a variety of things as we go through the design process. So, at the conceptual stage, it’s a concept tool, in the prove-out stages, it’s a prove-out tool, and in the prototype stage, it’s a prototyping tool – all from one machine.

We looked at all the machines and it turned out this was the ideal machine because it’s just so versatile. And the thing is that it’s working out the other way around now, the machine is so good that it’s driving the engineers to try out different ideas. It’s been a fantastic part of this new design process which we’ve invented.

AD: Do you think that because it’s a relatively small design team and a particular department doesn’t own the machine, everyone can see the potential?

GM: Exactly! We don’t have departments, we have a very flat management structure – it’s honestly that, just one office full of everybody. Design engineers, styling, conceptual engineers, electrical engineers, visualisation, graphics engineering database, research, everyone is in there. And it’s like that down in the workshop, we have a pattern maker and prototyping guy, but they all work together and talk together on daily basis. I swore, when we set this company up, we’d never get bigger than this facility; the core team will never get bigger than this building. For any other business we’ll have breakaway offices and they’ll have their own offices and management.

AD: Earlier you talked about using full size print outs. Do you see any difference between using these and full size projection screens for design review?

GM: We looked at the full scale projection-based screens, but for what we wanted to do (and to get something to the size that we wanted) we would need three projectors, they would need to be aligned and synchronized, and short of projecting onto glass, we couldn’t scribble on them – which is what we wanted to do.

It’s the same as the rapid prototyping machines. We use the 2D drawings and the orthographic prints as a scribble board. Go upstairs and you’ll see a view of someone driving the car and you see little balloons coming off it saying “move this 10 millimetres” or” be careful you don’t put this loom through the fuel tank” – that gets updated and it gets scribbled on again.

When you’re projecting onto full-size screens, it’s quite difficult to use it as a technical tool. If you’re using as a visualisation tool in the styling department, it’s a very good tool, but styling here isn’t a separate department; it’s fully integrated into engineering and styling is more engineering-led.

AD: If you look at the tools you have available now, is there anything you’d like to see developed to solve particular problems or bottlenecks you have come up against while developing the car? Where are the technology gaps?

GM: There’s still a bit of a bottleneck in that you can use all the tools we’ve talked about, you can use Catia, orthographic drawings, rapid prototyping, full CNC machining in rigid foam, but when it comes to tooling, while you can cut a tooling stack quite quickly on our machine out of tooling block, taking the next step in the tooling, is, to my mind, still, too slow. Now, there’re two ways of doing that. You can take splash moulds off your tooling stack – that’s quite quick. But these days, people tend to do a final male tooling stack, then re-machine all the tools using CNC programmes in female form and then lay-up in those.

If there was some way of rapid prototyping that with lightweight tooling, if there was a machine big enough to do lightweight tooling, that would be fantastic. For a lot of panels, you could just make the panel, and that’s quicker than doing any tooling stack, but if you wanted to make the panel with the real material, if there was some way of rapid prototyping a door skin, if you had a machine big enough, you could rapid prototype a door skin, but it’s not going to be in a composite, with short glass filled fibre skins, either side of a honeycomb core, and you wanted to make that via a rapid prototype, you’ve got to make a RP model or machine tools out of tooling block. If you could build that straight from CAD, and then lay up the tool. Maybe that’s coming, I don’t know.

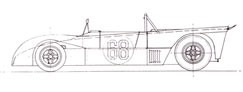

The Gordon Murray designed Duckhams Ford from the 1972 Le Mans. The car wore race number 68 and finished 12th overall.

AD: You obviously have a very efficient way of working, but how do you go about capturing that? Obviously, you’ve got the full scale print outs that you mark up, but how do you go about ensuring that it’s fed back to the people that have to deal with it – is it the fact that they’re all stood around a common point of reference?

GM: Exactly, that’s the key, innovation and skill. The simple fact that they’re all stood around a full-scale print of the car every Monday morning for a design review. Sometimes they last ten minutes, sometimes they last three hours and no-one gets to leave the big board until the problem is solved and we’ve agreed a solution. If you start getting into the “fill in the form and tick all the boxes and send for approval” then a car program will take six years and we can’t afford to do that.

We still do all the safety checks and have more formal reviews, but on a daily basis, it’s working on live information. And again, rapid prototyping is part of our communication, when we build a model, it doesn’t get hidden in the workshop, it gets brought straight into the design office. Everybody has a central table on each cell in the design office and that model will get plonked straight in the middle of everybody so they can see it. There’s a full size engine and gearbox. There’s none of this “blue collar, white collar” business, we don’t have to go down to the workshop and ask permission to see the prototypes; they’re sitting on the table in the design office. So, communication is key and I’ve always run companies like that and I’ve been running companies since 1974.

The racing legend discusses his design process