Eye Tech’s Maurice Hammond, piloting one of his own P51 Mustang aircraft

When Maurice Hammond founded Eye Tech Engineering in the Suffolk market town of Eye back in 1985, his ambition was simply to provide a top-class precision engineering sub-contracting service to other East Anglian businesses. But thirty years on, general subcontracting accounts for just half of Eye Tech’s annual turnover.

The other half comes from the restoration of Rolls-Royce Merlin engines and the manufacture of other components for vintage aircraft, from propellers to pistons.

Over the past 15 years, Eye Tech has been restoring Rolls-Royce Merlin engines at a steady rate of around two per year. The manufacture of new parts for these engines is strictly controlled in the UK, but Eye Tech has not only the official approval required to carry out this work, but also the CNC milling and turning equipment to achieve the best results.

Requests arrive at Eye Tech on a regular basis from enthusiasts from all over the world and, in order to keep up with demand and carry out this work as efficiently as possible, Eye Tech has recently taken delivery of three new machines from XYZ Machine Tools: an XYZ 3000 manual turret mill; an XYZ Mini Mill 560 machining centre; and an XYZ 2-OP portable vertical machining centre, for which Eye Tech was one of the first customers.

Says Hammond: “We knew we had to replace a number of obsolete machines from another manufacturer, as they were becoming unreliable and spares were getting harder and harder to locate as the company was no longer in business. Unsure which way to turn for replacements, we asked our freelance maintenance contractor and without hesitation he suggested XYZ.”

A visit to the XYZ showroom, Hammond continues, convinced him that the company’s range of machines were a suitable match for Eye Tech’s needs. In particular, he saw that they’d fit into the limited floor space on offer in Eye Tech’s machine shop.

This was particularly true for the 2-OP portable vertical machining centre: while it’s designed to be moved around a factory floor, at Eye Tech it stays in one place, but its small footprint means it sits snugly between two other machining centres.

Leah Young operating the XYZ 2-OP in Eye Tech’s machine shop

“The XYZ 2-OP is being used as a standalone machining centre, producing a variety of small parts that need milling, drilling, tapping and profiling,” says Hammond’s daughter, Leah Young, who joined the business in 2004 and now oversees the day-to-day running of the machine shop. Given its small size, she adds, its capacity and flexibility is impressive.

In terms of footprint, the XYZ 2-OP occupies 1,220mm by 760mm. At the same time, it offers a 50 to 6,000 RPM, 3 hp BT30 spindle; an eight-position toolchanger; axis travels of 355mm (X axis), 305mm (Y) and 455mm (Z); and feed rates of up to 15 m/min.

At 457mm by 381mm, the machine table has the capacity to hold components up to 250kg in weight. Control is provided by the ProtoTRAK system.

The XYZ Mini Mill 560, meanwhile, is used for small-to-medium batch work of between 25 and 1,000 components. It offers a 15 hp, 8,000 RPM spindle and axis travels of 560mm by 400mm by 500mm, supported on a 3,100kg solid-cast base and column.

With both machines, training was provided at XYZ’s Nuneaton showroom. The company also provides ongoing support, answering any questions Eye Tech has about programming the Siemens 828D ShopMill Control software on the Mini Mill 560 or the ProtoTRAK control on the 2-OP.

The XYZ 3000 mill, meanwhile, is mostly used by Maurice Hammond, who prefers manual machining, for jig and fixture-type work. It offers axis travels of 780mm by 410mm by 406mm and a Newall DP700 digital readout system for positional accuracy.

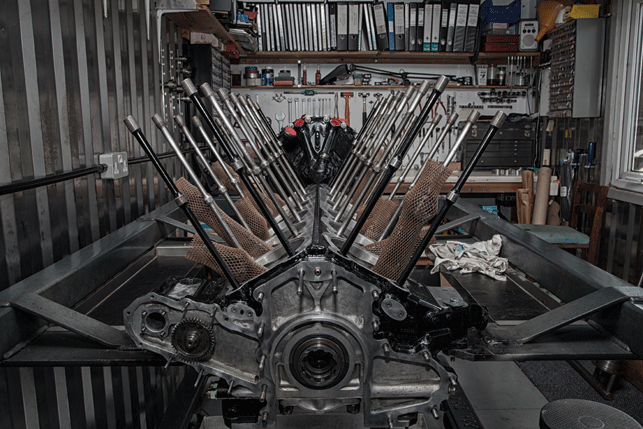

A Rolls-Royce Merlin engine awaits completion of refurbishment work

Leah Young praises XYZ’s customer service, particularly the expertise and fast response times of its applications engineers. “It’s also nice to know that XYZ stocks parts for all their machines and a service engineer can be with you very quickly to get you back into production,” she says.

eyetechengineering.co.uk

xyzmachinetools.com

Investment in CNC milling equipment pays dividends for EyeTech Engineering

Default