Deakin University’s recent expansion has made it an environment ripe for product development

The latest report into the state of the Australian manufacturing sector, published by trade and industry body the Australian Industry Group (Ai Group), contained both good news and bad for the nation’s economy.

On the plus side, the manufacturing sector expanded for the fourth consecutive month in October 2015 — the longest run of growth readings since July 2010.

On a more negative note, the result was only “mildly positive”, note Ai Group’s analysts, “suggesting stability rather than meaningful growth across Australia’s manufacturing sectors.”

At the School of Engineering at Deakin University, Geelong, course director Paul Collins is adamant that good product design lies at the heart of tackling the precarious state of the sector and represents a chance to resurrect Australian industry.

Many of his students, meanwhile, are focusing their attention on sports and sporting goods. It’s an accessible subject for them, he explains, and it’s an area in which it is relatively easy to get funding for research work. But it can also be a starting point for explorations that could expand into other areas: biomedical science, prosthetics, even lean manufacturing.

Take, for example, the final-year project of Deakin engineering student Robert Leen: a big snowboarding fan, Leen’s GripTight BOA System toys with the idea of 3D printing functional snowboarding bindings to create a more responsive ride.

Currently, to get the same effect, riders either tie their bootlaces tighter or over-ratchet the binding.

“What we found through a survey is that people get a lot of pain in their ankle — they’re cutting circulation off to their foot. And they’re getting pins and needles in their toes, which for a performance sport is really bad,” says Collins.

By using the snowboard boot as a semi-rigid member, rather than the ratchet gripping on top of the toes, Leen’s BOA system circulates the boot laterally rather than vertically.

“So as you crank it up, you’re not actually putting any pressure on the toes, you’re putting all the load through your boot, thus increasing the responsiveness without increasing pain,” he explains.

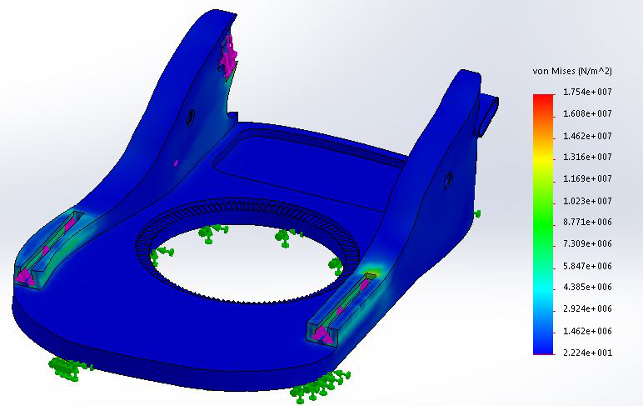

The end product is a 3D-printed part created via clever FEA analysis and digital materials, but as Collins points out, it was only at the back-end of the project that technology became key.

The snowboard bindings underwent thorough FEA analysis, with the data feeding back in to the 3D printing process

“One of my things is that I want to get the students to hold back on digital just a little bit,” admits the course leader. “We took a design thinking approach to [this project], which is very common across product development companies, but not so common inside research,” he says.

“Let’s go out and research, interview people, find their thoughts, ideate, come up with wacky concepts and get them out to our focus group.

“Once you’ve committed to digital then it takes more time, where a pen and paper is really simple and quick. You can do a sketch on the back of a napkin. Instant feedback is really critical to design.”

Technology matters

The thought process may be at the heart of the students’ work, but Deakin’s School of Engineering is nevertheless increasing its technology outlay.

3D printed test bindings were strapped to a board for real-world physical testing

For CAD, Autodesk Fusion 360 has been added to the school’s armoury and SolidWorks is also used. Its workshop and prototyping facilities, meanwhile, are now extensive, with an oncampus foundry and carbon fibre labs hard at work. In short, it’s an environment ripe for product development.

In the case of Leen’s GripTight binding, this set-up proved invaluable. A variety of physical iterations were produced from 3D-printed materials, using an open source Stratasys Objet Connex3 printer.

This was obtained through the university’s partnership with Australian reseller Objective 3D. In total, seven pairs of functional bindings were printed for testing.

This open source 3D printer allows users to ‘hack the code’, enabling them to develop new techniques and to introduce simulation data that influences the machine’s capabilities when it comes to producing digital materials.

The choice of materials was important, too, given the freezing temperatures and stress tolerances involved in snowboarding. Prototypes made from certain materials could immediately be ruled out, says Collins.

“You put Objet Vero in the freezer and it becomes brittle and snaps, which would be a big issue when it comes to snowboarding,” he says, adding that, contrary to the popular misconception of Australia as one big scorching outback, certain regions experience temperatures as low as -10C. “We do have snow,” he laughs.

Objet’s ABS-like material, by contrast, allowed for models that could be physically tested on the slopes of nearby Mount Buller.

“We had a couple of strange looks,” Collins recalls. “One of the ski instructors thought we were completely mad.” But as a YouTube video about GripTight shows, it’s a completely functional item.

https://youtube.com/watch?v=CwXmXzcI0mk%3Frel%3D0

Since graduation, student Robert Leen has gone on to become a research assistant at Deakin University, within its new Centre for Advanced Design in Engineering Training.

Students like him make Collins really positive about the future, he says, and there’s much more to come.

With the help of Australian government funding, the university is undergoing rapid expansion that has more than doubled the number of students attending.

“We’ve got some really cool students starting to come through, and a bit more of a start-up culture in the area, and that’s supported by the government as well, so I think the next five years is going to be a great period for Geelong – and for Australia.”

Deakin University’s design thinking approach for students

Default