DelcamWhen you look at the world of Computer Aided Manufacture (CAM) and drill down (no pun intended) into who’s doing what and what the different systems offer, you quickly find something of a split. Some applications concentrate on the ability to machine complex geometry and control highly complex machines (such as within the Mould and Die market) while others focus on the world of production machining, where equally complex machine tools (such as increasingly popular Mill/Turn configuration) are used to produce less complex parts, but in typically much larger volumes. It’s in this latter segment that Delcam’s FeatureCAM sits, and sits perfectly.

Delcam acquired the product a couple of years ago, and since then a number of things have happened. Support for 3D data has improved and the general look and feel of the system has been overhauled. In addition, where the system was perhaps best known for coding NC from scratch off the back of very basic 2D geometry (typically sketched by the user), it now has workflows for all manner of data sources and machining operations.

FeatureCAM imports the majority of standard CAD data, and includes several native file importers

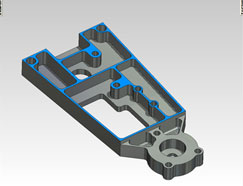

Whether carrying out basic 2.5-axis machining, 3-axis, 5-axis or into the realms of Mill/Turn, the key to FeatureCAM is that it is built on a very strong knowledge-based infrastructure. By that, I mean that it does an excellent job of capturing knowledge and data about all those parameters, variables and inputs that influence part programming, such as cutters/tools, operations materials, and feature types. This enables it to make intelligent decisions and automate much of the workload, which it does by relying on feature recognition very heavily. To illustrate this, let’s step through a basic part programming job.

FeatureCAM allows users to work with sketched geometry but a more intelligent way to work is to extract the required data from a CAD system. FeatureCAM supports all of the major translation formats (such as IGES, STEP) as well as a number of native formats. It also includes a range of native data import options, including AutoCAD, Inventor, SolidWorks, Catia (V4 and V5), Solid Edge, Unigraphics/NX, and Pro/Engineer.

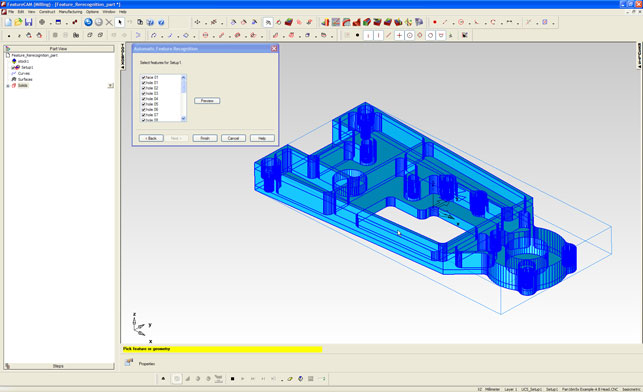

Automatic feature recognition looks for pockets, bosses, faces, grooves, chamfers and sidewalls – and uses best practice to apply operations to them

Whichever format is brought in, the workflow is the same. As with all CAM operations, the starting point is to set-up the global parameters for the job. That includes selecting the machine tool, the Z and X axes (so the system can orient it correctly), the origin and the stock material. When working with a turning or mill-turn operation things differ somewhat as these parts are revolved, but the basics remain the same. The geometry is imported (or created from scratch), the global parameters set up, and then automation tools are used to set-up each operation. To do this, FeatureCAM first identifies each feature (in terms of machining feature, rather than geometry) and does this using a proprietary algorithm (AFR, Automatic Feature Recognition), rather than reading the native features from the CAD package. This gives it more flexibility to adapt to machining requirements. The system will identify all the features it can, including Pockets, Bosses, Faces, Grooves, Chamfers and Sidewalls. It also does excellent work with holes, a seemingly simple feature, but one that can get quite complex when entering the realms of multi-stage hole drilling or boring and threading (both of which have seen work in this release).

The speed at which FeatureCAM uses best practices combined with an organisation’s standards to generate machineable forms, is pretty compelling

In the case of Mill/Turn, because of the nature of the beast, features are not quite as immediately recognizable, so here the IFR (Interactive Feature recognition) is used instead. This does much the same job as the AFR, but the user needs to give it a helping hand by selecting geometry profiles, for example.

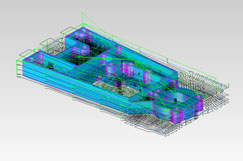

Toolpaths are generated very quickly, using best practice and company standards – but can also be adapted

Once the geometry features are assigned, the system uses the common set of defaults for each feature type, creates the tool-path and the NC code, and then places each operation in the results window. As mentioned from the outset, speed is key to FeatureCAM. Instead of spending time creating each operation manually (selecting geometry, applying specific cutting conditions and tool-path variables) time is spent upfront prepping the system so it can blast through the process. Then, if a specific operation needs to be adapted, the user can dive in and edit it.

FeatureCAM goes so far as to monitor each feature as it’s added to the results windows so it can re-order it automatically to minimise tool changes/reduce rapid-moves, height etc. Of course, this can be switched off and the operation list can be ordered by hand to achieve the required results.

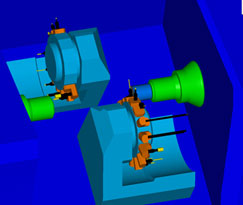

Machine Simulation allows users to ensure NC code is as perfect as possible, before cutting material

What’s interesting about FeatureCAM is that it manages to compress the CAM programming process greatly using two key methods. Firstly, it delivers usable NC code very quickly, which is facilitated by using intelligence and knowledge. Secondly, it lets the user adapt first pass results to get the required results, in a very short space of time.

Conclusion

FeatureCAM is one of those rare products where everything is immediately clear. Data import is simple and the tools to construct geometry for machining from scratch are also straightforward. The use of technology to identify features within a machinable form is not by any stretch of the imagination, unique, but the speed at which FeatureCAM uses best practices combined with an organisation’s standards to generate machineable forms, is pretty compelling.

What’s also interesting is that while Delcam continues to add greater support for more and more complex machine tool types and configuration and processes, it seems to be doing it without adding complexity, so the system retains its core tenet of ease and speed of use.

To sum up FeatureCAM succinctly, it offers some very nifty tools to get cutting material in the shortest time possible.

Feature

Turn/Mill updates

Mill/Turn machines are rapidly becoming state of the art for many contract machine shops, particularly those looking at less complex, but very high volumes parts. The ability to bar feed material and have multiple heads carrying out simultaneous operations and automated changeover of parts, means that parts can be produced very quickly indeed.

Milling is something that FeatureCAM mastered some time ago, but with each release, Mill/Turn support is improving in both raw operation capability and some of the finer aspects that’ll pay dividends when using the system. A good example of its raw capabilities is the addition of support for Slant Turning added in the 2009 release. This is useful for machining difficult areas which perhaps have different undercuts or depth, and it can do this without changing the tool set-up. The system defines angles of attack and adjusts the cutter slant angle to achieve the desired results.

Meanwhile, usability is enhanced to ease working with multi-turret machining. In previous releases, the multiple turret and synchronization interface was implemented horizontally in the UI. However, this isn’t how NC guys are used to having their data presented (it’s usually two vertical lists of G code inspected side by side). The sync window has been redesigned to allow operations to be organised by turret and by time. This makes manual validation of the code possible, which gives experienced users an element of trust in what would traditionally have been a very manual process.

| Product | FeatureCAM 2009 |

|---|---|

| Company name | Delcam |

| Price | On application |