The use of laser scanning as part of the design process has been growing over the last few years.

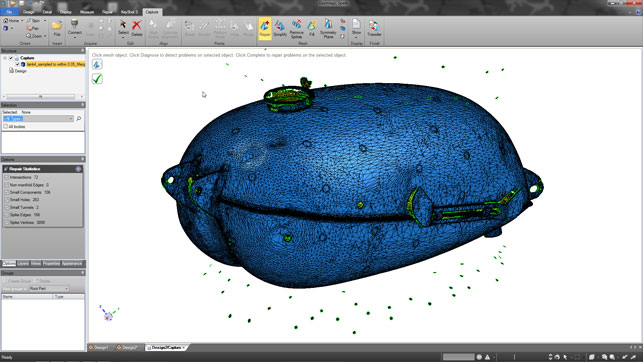

Figure 1

The drive to work more efficiently, the need to capture existing products or, indeed, physical concepts is something that we’ve always been familiar with. What’s changed is that the technology is starting to come down in price and frankly, the process is becoming easier to use.

For instance, devices such as the Microsoft Kinect are starting to offer a dramatically lower entry point.

That said, the capture of a physical form is not a hardware only solution; software is needed to post-process the scan data. Its use often depends on what the user plans to do with the scan data once they’ve got it.

Many are looking to rebuild clean CAD-style geometry from their scanned forms. There are a couple of ways to accomplish this. The first is to ‘drape’ a set of surfaces over the points and create an accurate representation of the captured form.

The problem is that this is often a one shot deal and editing that data is problematic, due to the heaviness of the surfaces generated.

The other method is to use the scan data to build analytic surfaces or, more recently, to use it as the basis for reconstructing a feature-based model.

All of the key vendors in the space are working towards this goal, each with slightly different approaches. RapidForm’s XOR system uses tools to build explicit features that are transferred into the user’s CAD system, building up a history tree.

Delcam’s PowerShape provides tools to build surfaces and solids from reference geometry. Geomagic has, for some time, been working on a feature-to-CAD approach with connections between its Studio product and the leading 3D design systems. Into this comes another approach from Geomagic with its Spark application.

What is Spark?

Geomagic has licensed SpaceClaim’s direct modelling system and is building in tools from its Studio product to create Spark. The software is in beta at the moment and due to ship in a few months (Editor’s Note: Spark actually shipped just as this article was posted – in fact, there’s a free trial available now).

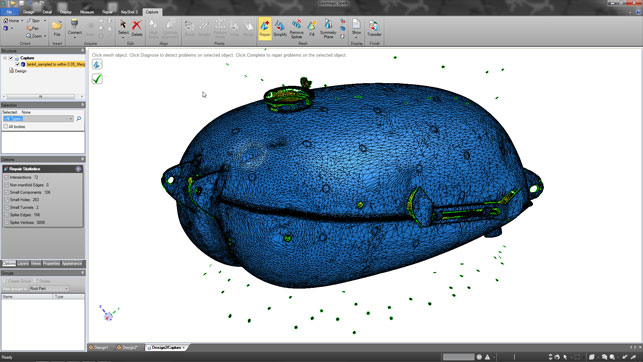

Spark is a Geomagic application and will be sold through its reseller channel, which shall soon be part of the 3D Systems organisation. Spark takes SpaceClaim’s direct modelling tools and combines them with the scan data post processing tools from Studio.

This provides a set of tools for not only capturing point cloud data, but taking it through to analytic CAD geometry, in a single application.

While other CAD systems might allow users to import STL data, Spark goes one step further and enables users to work with their scanning device directly from the interface.

The first step is to create a Capture and Design document. This is essentially a split file that in the Capture portion allows the user to work with point cloud and polygons while the Design document is used for analytic geometry creation.

Capture: points & polygon

Let’s deal with the Capture document first. It’s here that the user connects to their scanner (Spark supports Creaform, Hexagon or Faro scanners).

The data can be streamed into the interface and viewed as the user works through the specific scanning process. It also affords tools to align separate scan sets, optimises that point cloud as well as the identification of hard features, such as planes, cones, spheres and cylinders.

If the user does preprocessing in the tools supplied with their scanner, Spark will enable them to import datasets from a wide variety of formats. Points come in using ASC, PCN, SCN, VTC, 3PI and many others. It’ll import Polygon mesh data from G3D, OBJ, PLY or the old standard, STL.

This means that the user is not restricted to using scanned data and the system naturally has the ability to import mesh data from a CAD standard, which can be reverse engineered.

Whichever route or process is used, the Capture window also provides tools to repair, improve and optimise the mesh data.

This could be removing noise data from the scan (Figure 1 shows noise resulting from the optical scanning process) or disconnected polygons, spikes or hole filling, including Geomagic’s curvature filling tools. All of the options and inputs are found either in the window in the top left corner or the Options panel to the right.

On the subject of hole filling and repair, for those experienced with Geomagic Studio, it’s worth noting that Spark doesn’t currently have the more advanced polygon repair tools that allow portions of mesh to be deleted and bridging geometry added in to complete areas where a scan has failed to capture.

I’d hope these are included in the final release as they can get the user out of problems with a mesh without having to rescan portions. Once the mesh is repaired, processed and in a suitable state, it can then be transferred into the Design portion of Spark.

Design: From Polys to Surfaces

The polygon model is transferred using, as you might guess, the Transfer command. What this does is take the polygon mesh and transfer it into a SpaceClaim-based session. It’s held in a separate window and doing so immediately opens up all of the operations in the system.

Here all of the existing tools are available for the user to work with in a direct modelling manner. What Geomagic has done is supplement these with some of the other tools available in the Studio application that make working with polygons much easier.

This manifests itself in the use of regions and standard feature detection.

Spark can run the detect regions command which identifies any areas that conform to standard features, whether that’s cylinders, spheres, planes and such. It’ll identify these regions and allow the user to quickly fit the appropriate primitive solid geometry. Unless you have very prismatic parts,

I found these aren’t much use and a more manual method has to be used. This brings in another area where Geomagic has enhanced the existing SpaceClaim tools with new selection methods.

The magic selection

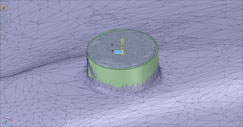

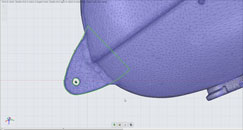

Consider the form shown in Figure 4. This is clearly a cylindrical boss.

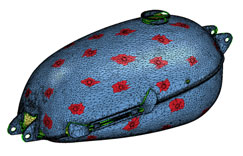

The combination of the age of the part and the scanning process means that the details are pretty bashed up.

The figure is of a 1950s Triumph motorcycle tank that’s been kicked around for the best part of half a century.

It was scanned with the help of the folks at Solutionix with its new Rexcan CS system, a structured light scanner and turntable combination. I think it’s done a fantastic job of capturing just how battered it is.

Using the Cylinder fitting tool, select a facet on the side of the cylinder and drag the mouse up.

This will ‘grow’ the selection around that feature. Selecting OK will place a solid cylinder that matches that selection. Now, it’s not going to be 100 per cent bang on, but here the benefits of direct modelling come into play.

The top face can be grabbed and ‘pushed’ to a referenced facet on the top of that boss. This will snap the faces into the correct position as shown in Figure 5.

Obviously this boss also has a tapped hole for attaching the petcock, but when it comes to scanning these types of features, it’s perhaps best to fill in the extra details and just use a vernier to measure by hand and model directly, dialling in the values as required.

Dealing with the complex

While adding in easily identifiable features seems like a good way to work, if I’m honest, the times when that is both appropriate and actually works, seem few and far between.

If the product that is being reverse engineered can be broken down into very simple prismatic features, then you have to ask yourself why you’re laser scanning in the first place. A couple of measuring devices from Machine Mart will do the job just as quickly.

Where laser scanning excels is at capturing those forms that are difficult to measure manually, where size means that references can’t easily be gathered together in a meaningful way, or as in our example, if the part is not ideal and features complex forms that don’t lend themselves to hand measurements.

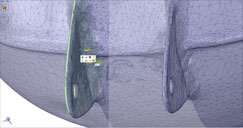

It’s here that the Spark tools for diving into the model, extracting profiles and building features manually start to pay dividends. In the motorcycle tank example, the mounting brackets are a difficult form to first measure, then place accurately in 3D space.

Section editing and references

Using a combination of SpaceClaim’s ‘section edit’ mode and some improved sectioning tools from Geomagic, it’s possible to place a sketch plane through the brackets and start to redefine the profiles.

While some of this could be done using SpaceClaim, Geomagic has added a number of tools to assist with finding standard forms — such as straight lines, arcs and circles — which can be used to build cleaner sketches.

If the user is working with a clean scan, or indeed, STL data from a CAD system, then they can extract these ‘as is’ and run with them, building the geometry out into 3D quickly and efficiently. If not, then they can place known features and build out the rest.

Figure 6 shows how circles and arcs can be placed, using references from the section, then the required form added in using tangency where appropriate.

Once it’s complete, the sketch can be manipulated using the direct editing tools and limits defined by taking references from the polygon mesh using the ‘Up to’ option, available in most commands and operations (as shown in Figure 7).

Conclusion

With Spark, the combination of a flexible modelling environment as found in SpaceClaim with Geomagic’s mastery of manipulating point cloud and polygon geometry is looking compelling. Saying that, there is work to be done.

While working with clean and prismatic geometry is pretty effortless, as soon as you get into working with more complex surfaced forms (such as the main section of this motorcycle tank), it starts to fall down.

While it’s possible to work in Geomagic’s Studio application to repair, reconstruct and build a decent surface model, in Spark there’s an issue.

The freeform feature doesn’t work well without the control that is found in Studio. It’s also not helped by SpaceClaim’s inability to create and edit complex surfaces. Geomagic needs to find a way of fixing this, because until it’s solved, there’s always going to be a stumbling block in the workflow.

Spark isn’t a unique solution in this space as there are a number of options out there but what it does do is bring a new method, something that’s not been tried before. I for one am certainly interested to see how it develops, particularly now in light of the 3D Systems acquisition. If you fancy a go, grab some STL data or perhaps your own scanned data, in fact, download the free trial, and see what you can do.

| Product | Spark Beta |

|---|---|

| Company name | Geomagic |

| Price | €8,900 |