With the launch of AIM last year, Ansys brought its wealth of experience in simulation to a system targeted at mainstream designers and engineers. One year on, Al Dean takes a look at how AIM has evolved since its introduction

Last month, we took a look at major improvements included in Ansys Workbench R17, an update that focused on automation and the streamlining of workflows that many find time consuming and repetitive.

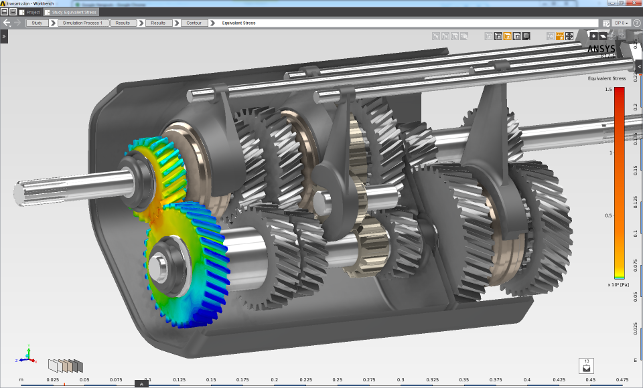

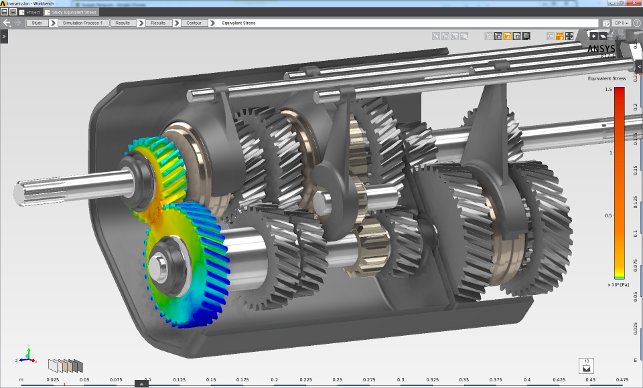

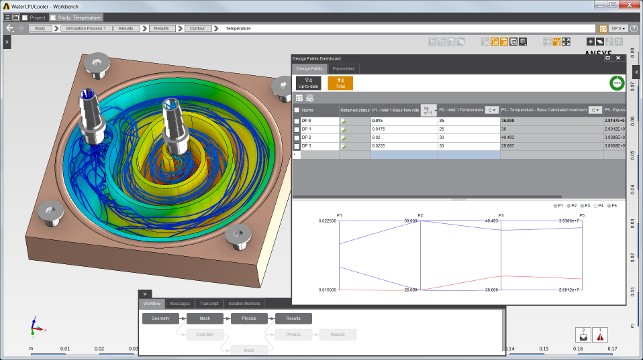

Here, Ansys AIM is used in the mechanical design of a vehicle transmission system

However, while Workbench is the vendor’s flagship product, Ansys has another ace up its sleeve: Ansys AIM.

Ansys AIM was launched last year (we reviewed it in July/August 2015), with the aim of bringing Ansys’s knowledge, experience and technology in the simulation realm to a new platform designed for mainstream users, rather than the experts who represent the majority of the Ansys customer base.

Ansys AIM, to recap, is built on the Workbench platform, but rather than exposing every feature and function, the goal is to provide users with a way to take a product model through the simulation process in as short a time as possible.

While this isn’t a unique goal in the simulation space, what sets AIM apart is that it’s built on top of a platform that offers some of the most respected and, just as importantly, most validated simulation code available.

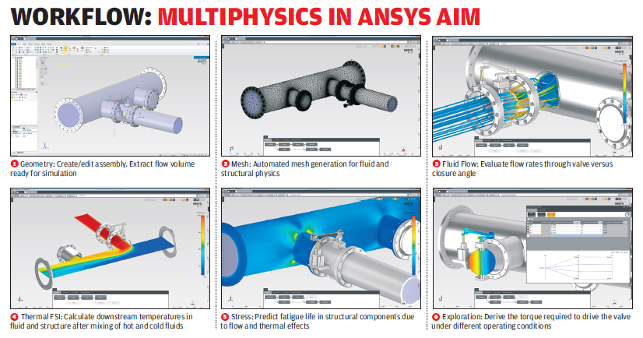

Equally critical, Ansys AIM has been designed from the ground up to support multiphysics problems.

As we commented back when the product launched, the separation of physics models (linear static stress, nonlinear, fluid dynamics, thermal and so on) is a stumbling block for many users, since the process of ensuring good use is traditionally a complex business.

Ansys AIM intends to break down the barrier by allowing the user to simulate their product using whatever physics models are needed and have the system do the heavy lifting when it comes to the most complex parts of the process.

Ansys delivers this by pre-baking a set of workflows or templates into the system that allow you to conduct specific types of simulation.

The first release focused on the basics of fluid flow and stress analyses, but as we’ll discover, with the next major release, the range has been expanded – so let’s dive straight in.

Ansys AIM – User experience

Ansys AIM is unashamedly workflow-based. Whatever type of study you’re conducting, you’re led through the process by the system and given clear indications of what’s needed in terms of input and what’s still missing.

The user interface reflects this approach, by hiding the usual options and operations you’d expect in a simulation system and instead focusing the user on each stage as they progress through study definition.

The first step is to choose the type of study you’re looking to conduct. After all, if you’re focusing on a fluid flow analysis, this has very different requirements to a linear static stress analysis, both in terms of how the project is set up (in terms of mesh, boundary conditions and so on) as well as the workflow.

Ansys AIM – Study set-up

Ansys AIM launched with a ‘bare bones’ set of templates. Multiphysics, meanwhile, was restricted to a single-direction link between fluid flow and linear static analyses. These capabilities, of course, have been expanded in this release.

There’s now a much larger set of templates, ranging from electrical conduction analysis, thermal analysis and fluid structure interaction, as well as the usual stress and vibration studies. The latest R17 release also now introduces fatigue life.

The next stage is to set up the geometry for your study. In the initial release, this involved importing your CAD model and checking that the model was in a fit state (in terms of feature abstraction or defeaturing).

For this release, Ansys has integrated SpaceClaim’s modelling tools — one of the benefits of Ansys now owning that CAD system.

This means that you don’t necessarily need to do all of the pre-processing of your geometry outside of AIM.

Instead, you conduct that work inside the interface, whether that’s segmenting the model, generating internal or external fluid volumes or removing small and/or inconsequential features such as fillets, for example. It’ll even allow you to work directly with mesh-based geometry if you need to.

This release also sees the introduction of automatic contact detection for fluid structure interaction. While it was there before for single physics problems, this has now been expanded to automatically find areas of contact, where stresses are passed between two physics models.

You’ll also notice that there’s been an overhaul of the graphics display in all of Ansys’s products, bringing things up to date and enabling a much richer visualisation of models and results.

Once your geometry is prepared, you are then guided through the various steps that go into making up your study. At each stage, you’ll see where information needs to be defined and where you can add more detail.

Depending on the study you’re working on, you’ll be prompted for various inputs and variables to be defined, but soon enough, you’ll find that your study is ready to run.

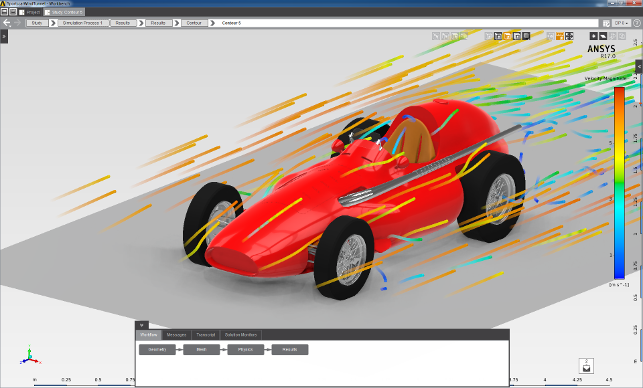

The AIM Virtual Wind Tunnel app allows rapid design optimisation of components subjected to aerodynamic loading

Ansys AIM – Design exploration

Alongside the updates we’ve discussed,there’s another new capability in Ansys AIM that’s worth a little time and attention, relating to design optimisation and exploration.

Most implementations of such tools require that you have a simulation system closely linked to a means of driving a parametric model.

You set a range of variance for the key parameters in that model and the system conducts a specified number of iterations that vary those parameters, judging the results against specific design goals.

The issue with this approach is that it relies on you having an exposed set of parameters in your model that you can control to drive the shape of the part. This raises two problems.

First, if your geometry is ‘non-native’, you don’t typically have access to those parameters at all.

And second, if you do have a native model and are able to drive those parameters, the chances are that the parameter you want isn’t actually used to construct the model in the first place.

The end result is that you need to remodel the part or set of parts with the goal of design optimisation in mind.

Now consider Ansys AIM and the benefits of a simulation system that’s linked to a direct modelling system like SpaceClaim. One of SpaceClaim’s strong points is the ability to work with ‘dumb’ geometry and add in controlling dimensions that can control geometry after is has been designed (this is by no means unique to SpaceClaim, but it is rare).

With the combination of Ansys AIM and SpaceClaim, you’re now able to take a set of geometry, apply your geometry parameters as you need them for design optimisation (without having to rebuild the geometry from scratch) and expose them in a design optimisation study, saving you a great deal of rework.

Design Exploration: maximum temperature and stress versus cooling flow rate and inlet temperature in a CPU cooler

Custom templates

While much of the effort in Ansys AIM is laser focused on creating a set of ready-to-use and validated workflows, the underlying architecture of AIM allows the user to customise their own workflows to suit their own purposes.

In the initial release, this wasn’t exposed to the user, but that changes in the R17 release. You are now provided with a set of tools that allow you to use Python scripting to build your own templates for guiding users through specific simulation tasks, so that they do so in keeping with individual company standards and established, application-specific best practices.

Ansys uses the same set of tools to deliver each template or workflow and the potential is huge.

What’s interesting is that Ansys is building an app store-like central repository for these customisations so users can share their work with each other. It’s all done in a very open environment and it’s even possible to take the product’s baked-in workflows and

use these as starting points for your own customisations.

Ansys has also provided some excellent examples of its own, such as its wind tunnel workflow, which rips you through the set-up process in a fraction of the time that would traditionally be required.

Conclusion

When Ansys AIM first launched, I boldly stated that it was the “one of the most exciting developments I’ve seen in the simulation space for a good long while.”

At the time, I was eager to see how it would develop in the future and, having looked at what the team has accomplished during the product’s first year, I’ve certainly not been disappointed.

In short, Ansys AIM is still, to me, a very exciting development: it has the potential to bring multiphysics to a much wider audience by building best practices into pre-defined workflows and stripping out the often-arcane language and processes associated with simulation.

In short, the set of updates we see in this R17 release are nothing short of remarkable.

With Ansys AIM, the vendor is offering a set of technologies that tackle head-on many of the sticking points that previously prevented wider adoption of simulation technologies.

| Product | AIM R17 |

|---|---|

| Company name | Ansys |

| Price | on application |