In our last review of Onshape, in the May 2015 issue of DEVELOP3D, we took a look at the basics of how the system operates and, in particular, at how its cloud-based, browser-led nature changes perceptions of how software should be defined. We also delved into the details of what was available when Onshape first launched its public beta.

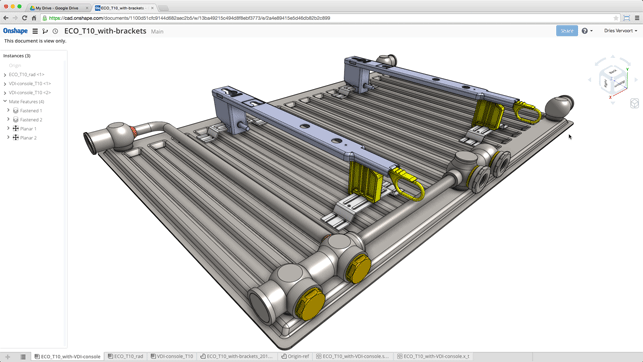

An internal component of the ECO Radiator designed in Onshape, by Stelrad Radiator Group (henrad.eu)

Our goal this month is to bring things up to date: What’s been added to the system, how have workflows changed and how is the system progressing generally? As with most cloud-based systems, updates come fast and furious with Onshape. With a monthly release cycle, it’s only too easy to turn away from the system for a short period and, on returning, struggle to figure out what’s new and updated without digging into the release notes — and who has time for that?

To save you the hassle, we’ll be providing a round-up of some of the bigger introductions to the system, as well as some of the smaller details, which are often just as interesting.

Modelling capabilities

Right now, Onshape is mostly about creating 3D models and collaborating on them with others. Until we start to see the introduction of drawing and documentation tools, 3D tools are the key focus.

At launch, Onshape had a good set of tools covering the usual set of operations – extrude, revolve, sweep, fillet and so on. There were, however, some glaring omissions when you consider the needs of today’s more discerning CAD user, including lofting.

The good news is that lofting has now been added to the feature stack, giving Onshape pretty much the full set of basics. It’s pretty solid, giving you tools to define guide curves in order to assist with shape control, as well as vertex matching.

The latter is particularly useful when combined with the split curve operation, so you can ensure that you’re lofting between profiles with matching numbers of vertices, giving a much more consistent and robust end result.

Work has been done across many of Onshapes’s features and operations, although not so much in terms of introducing new features, but rather, expanding the options within existing ones. As an example, the extrude function now offers more options when building features in multiple directions from the sketch. Another is the ability to not have an open face in a shell operation, so that the whole body is hollowed out.

That’s not to say that users won’t find some brand-new tools. You can now add text into sketches for building features from, for example, and there’s a whole new feature that gives you standard, counter-bored and counter-sunk holes. There’s no sign of standards-based holes, but I’m told this is coming.

Assemblies

When it comes to defining assemblies, Onshape takes a different approach from every other system on the market – something we discussed last time around. The modelling environment takes a multi-body, multi-part approach, which means that all of your modelling is typically conducted within a single ‘Part Studio’.

The Onshape team is currently working on an external references capability that will allow you to work with reference data (as is traditional in most mainstream design systems) — but in my view, there’s no real need for it when everything is modelled up in the same Part Studio, other than for managing data reuse.

That said, the most recent update brought the Derived Feature, which goes some way to solving this issue by allowing you to connect up the data held in separate Part Studios belonging to the same project.

When it comes to building assemblies, things aren’t quite so clear. An Assembly Studio is used for pulling together all of the parts and creating the joints and constraints that allow you to flex it. There’s no modelling in this context. It’s all about testing your moving parts.

There’s been some expansion of these critical constraints in the system; most notably, the introduction of the rack and pinion relation, as well as screw/linear relations.

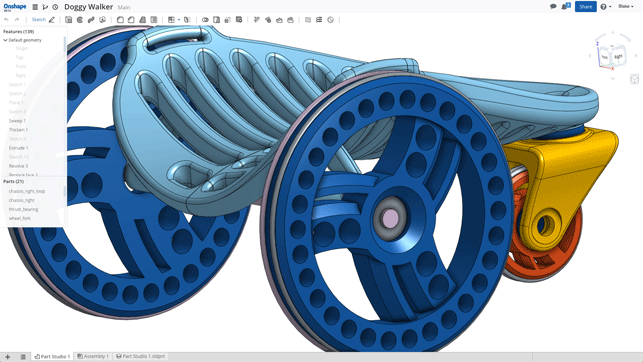

Doggy Walker wheelchair model built in Onshape by DD Studio (ddstudio.com)

Small details, big gains

What’s interesting in Onshape’s development is how, as use of the system increases, seemingly small changes are made that correlate closely with customer need. This is a big benefit of cloud delivery: because the vendor can closely track which features and functions are being used, where and when, it can respond quickly to user behaviour patterns, both positive and negative, in its monthly updates.

Take, for example, how a CAD system user interface typically deals with changing increments in a dialog: you usually get a fixed value when you push ‘up’ or ‘down’ on your keyboard or use some overly complex ‘dial’ widget.

With Onshape, by contrast, you can now scroll using your mouse wheel, but hitting a key will allow you to adjust increments: with Shift, values will jump by 10; with CTRL, you’ll get a smaller increment of 0.1.

Data IO

Data translation has also been a focus in the last few releases. Last time around, we discussed how there was some confusion around the uploading and importing of geometry, for example. There’s been some work done to address this and make the process more obvious.

For example, when you now upload a geometry file that Onshape can translate and work with, the translation is performed automatically, rather than the user having to choose to translate it. Elsewhere, the Export option has also been streamlined, so choosing to export a file from a tab will first translate the geometry, then offer it for download in the browser.

Also on the subject of data translation, there’s been some work done on supported formats. First, you can now import DXF files into sketches. Second, and for those looking to experiment with Onshape alongside SolidWorks, there’s better support for SolidWorks data if you’re exporting it using the ‘Pack and Go’ function.

Simply export the data as a zip file (one of the options in SolidWorks), upload that to Onshape and all of your data goes with the file, which it is automatically translated and ready to work on in both Part and Assembly Studios.

SpaceMouse a-go-go

It seems that those of you who use 3Dconnexion devices are pretty insistent about software vendors supporting your tools. From talking to the Onshape team, support for 3Dconnexion’s 3D computer mice was the second most requested feature!

What’s intriguing here is that how this has been implemented. A browser-based system like Onshape doesn’t lend itself well to interfacing with control devices like SpaceMouse — but the necessary work has now been done and as long as you’re running the 3DxWare 10.2.8 driver (and close your browser when installing), you’ll be able to pan, zoom and rotate to your heart’s content.

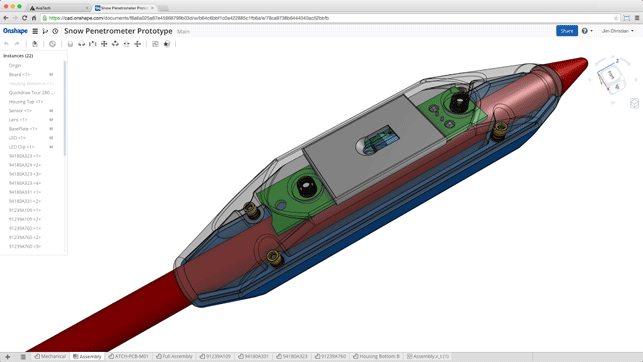

Avatech (avatech.com) is using Onshape to improve a device for finding potential trouble spots in the snowpack and sharing real-time safety data

Data management and collaboration

Onshape’s project management and collaboration tools haven’t changed in the period since Onshape Beta was made publicly available — the reason being that this was the area that took up the greatest proportion of the team’s focus in the run-up to launch.

To recap, because Onshape stores all of your data in the cloud and you’re essentially interacting with it while it sits on the Onshape servers, the system has an innate knowledge of how your model develops. That makes it possible for Onshape to offer version management for free, with a full history of how your product models are built.

On top of this, Onshape has built collaborative tools that take advantage of its cloud architecture, so that authorised partners working together on a project can easily log in and access data in order to edit geometries and provide comments. All this has been there since launch.

Yes, there’s been some tweaking here and there: the ability to comment on a geometry is now more targeted, for example, so that you can even add in comments to features in the history tree. (This is ideal of recording design intent, particularly during collaborative sessions).

Another thing to look at is the more recently introduced Compare function, which allows you to grab two parts (or two versions of the same part) and perform a very detailed comparative analysis — not just geometry/topology, but down to the feature list, sketch and feature-by-feature difference, but in a graphical manner and using lists of the selected entity.

Conclusion

Onshape is still, officially speaking, in beta, but it seems that some folks are already using it production — sometimes on its own, but more commonly, alongside existing tools. We’ve given examples of some of that work alongside this review and there’s a more detailed account below of how one company, Crave Innovations, uses Onshape.

As a tool to be used alongside your existing systems, Onshape offers some interesting potential. Collaboration, for example, is one of its strengths: having your data in a secure environment, with access control, but available to partners to view and even edit if needs be, makes perfect sense. Add in all of the version management and branching and merging tools, and you’ve got an environment that’s rich for engineering and design collaboration, over and above purely sharing models that can be spun or zoomed in a web-browser.

For many CAD users, Onshape is interesting, but not quite ready to be considered as a replacement for their workhorse tools — why is that? Perhaps the overriding reason is their need for drawings. Most products need to be documented. Production drawings are still vital — and for these, we need good, solid drawing tools. According to Onshape head honcho Jon Hirschtick, these are coming in the next month or so, with a pretty decent level of depth (they’ll include GD&T, for example). They’ve been developed in conjunction with Graebert, which already develops Dassault Systèmes’ DraftSight application, so there’s plenty of knowledge already there.

So how is Onshape looking, six months after launch of its Beta? I think the answer is pretty clear: the team is churning out updates that add in new functionality, but it’s also adding more ‘meat’ to existing features. It’s also supplementing workflows around geometry creation and editing tools in the areas of collaboration and data management. To my mind, this latter part is key: after all, it’s these areas that set Onshape apart from desktop-bound competition. Yes, the modelling tools are slicker than many (if not as well developed yet), but for me, the real killer app for Onshape and the area in which it can make radical improvements to workflows and the design process, is collaboration.

Either way, it’s fascinating to watch each release roll out — and it looks like Onshape’s doing more than enough to make folks sit up and take notice.

UPDATE:

Well, that’s just typical, you publish an update and then the team roll out those tools – here’s a quick video on where Onshape drawings is at now. It looks slick, well integrated (even if there are slight differences in the UI between the drawings environment and everywhere else). It’s got some solid drawing view layout tools (as you’d expect), sections and such, but also has a good selection of drawing templates, it’s multi-sheet and looks good.

There are also some additional items in this update worthy of a note. Firstly, extrude now comes with a draft option (yay!), there’s easier manipulation of fillets, and there’s some work been done on the lofting tools, specifically, adding in conditional controls over how lofts match surrounding geometry (by tangency or curvature).

https://youtube.com/watch?v=AKvWYyPC4dU

Crave Innovations: Changing an industry with Onshape

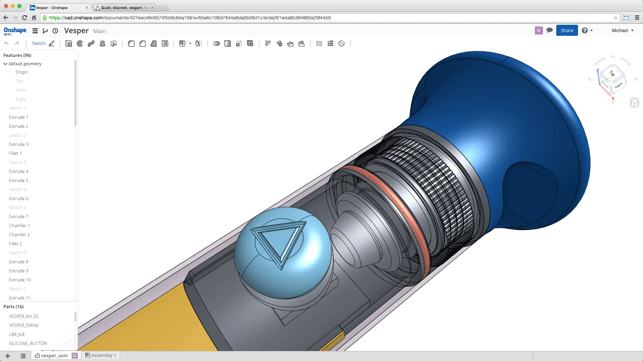

When you’re in the luxury adult sex toy business, you can expect a lot of nervous giggling and bad puns about ‘generating buzz’. But for Crave Innovations founder Michael Topolovac, the marketing challenge doesn’t end there.

“For many years, this category only existed in the novelty space,” he says. “It was all about the tee-hee bachelorette party experience with lots of bunny rabbits and smiley faces. We’re moving it to a more modern artistic space, where design is appreciated, [just] like it is with a fitness accessory or mobile phone.”

“If you look on Amazon.com, at any given time there will be between 100,000 to 200,000 [adult toy] SKUs in their health and wellness section. And almost everything is very phallic or cutesy, not modern and thoughtful.”

Founded in 2009, San Francisco-based Crave does all of its design and prototyping work on an in-house basis — and in order to streamline its design process, it’s now using Onshape.

Onshape enables multiple designers to collaborate on the same CAD model

Collaboration in real time

“We’re not afraid to take design risks,” Topolovac says. “We’ll build 20 to 30 prototypes of products that consumers think was mass produced and we can prove a concept of design in a weekend.”

“The big reason we chose Onshape is that we can have four or five engineers working on the same project in the same space,” he continues.

“The old way was sharing files with Dropbox. PDM is such a burden. You have to check files in and out and there is a lot of friction. We want our design process to be as fluid as possible.”

When working on new designs, Topolovac says he feels more secure using a CAD system that’s especially built for the cloud. “I like Dropbox, but it’s just not designed as a global CAD vault. Onshape just feels a lot safer.” It’s like the difference, he says, between keeping money in a mattress in a bad neighbourhood or choosing to put it in the bank.”

Convenience of the cloud

“I also love having everything in the cloud because all updates are automatic and I don’t have to spend time doing software upgrades. I can spend my time designing products,” he adds. “Traditional CAD is very cumbersome. I was hoping that someone would do this.”

Always aiming to make adult toys less cumbersome and less taboo, Crave regularly solicits feedback at ‘Build-a-Vibe’ workshops, where customers learn how to assemble their own devices.

Although most of these events are held in adult boutiques, Crave recently hosted one at the more mainstream California Academy of Sciences Museum.

“It’s a sexier version of Build-a-Bear and it’s a destination experience for a couple who may not otherwise engage in this conversation,” Topolovac explains.

“Part of what we are doing is bringing design to a category where it has largely been void, in support of an experience that can be a pretty important part of our lives. And more generally speaking, we aspire to create more space and opportunity for the exploration of sexuality, intimacy and pleasure.”

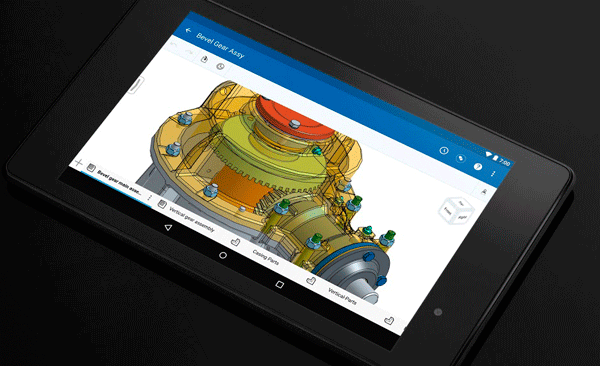

Onshape & mobile: now available for Android

Around the time that Onshape started to make its browser-based system available, it also rolled out its first mobile app. As we detailed back then, Onshape began with an iOS-specific app that enabled you to not only view and interact with your data on an iPhone or iPad, but to also conduct real design work — even if you did need to the fingers of a small child to do this on a smartphone.

OnShape offers most of the full-browser tools on Android devices such as the Samsung Nexus 9

It seems that this has gone down rather well with many users. I’ve personally seen people giving demos to other folks using the small rectangle of technological magic in their pockets.

But what about those folks with non-Apple devices? The answer has been rolled out just this last month: if you’ve got a reasonably up-to-date Android device (I’m told you need Android 4.3 upwards), then you can download the Onshape application and get it up and running on your device.

| Product | Onshape |

|---|---|

| Company name | Onshape |

| Price | Free to $100 per month |