XJet machines testing new materials at the AMC

Israel is on a different level when it comes to technology start-ups: a small nation of 8 million people, but everywhere you look there are industry pioneers and established brands across multiple verticals.

Emerging from this hotbed of innovation is a new player to the world of additive manufacturing, XJet, and it’s at the launch of its new $10M Additive Manufacturing (AM) Centre just south of Tel Aviv that we get our first real look at its potential.

A year after the public launch of its Carmel AM series of 3D printers, the chance to get up-close to the working machines and see the full process from design to end-use part was as exciting as the technology’s basic premise.

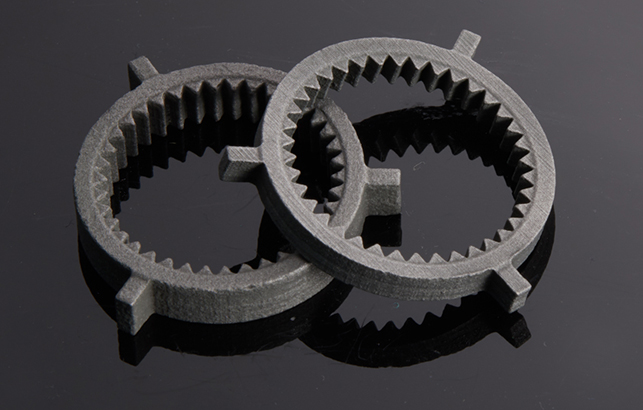

On paper it’s an intriguing process: based on jetting nano-particles of materials much smaller than those of traditional powder bed processes (enabled by suspending them in a liquid) and building up the layers to form 3D metal or ceramic parts.

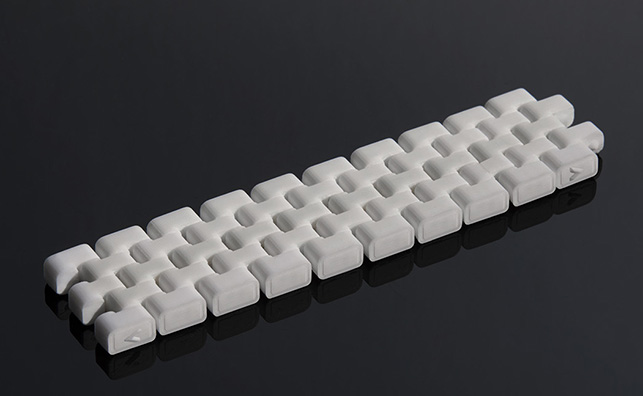

Soluble support materials allow any geometry to be created, while the nano-materials allow super high-resolution surfaces and higher density parts once the part has been fired in a kiln.

The Carmel system is capable of printing parts at resolutions of up to 3-8 microns for metals and 10-15 microns for ceramics, an astonishing ability.

To put this into perspective, most metals SLS-type methods typically print at 50 microns per layer, or at around the 50-100 microns for HP’s Metal Jet binder jetting.

On paper it’s an intriguing process: based on jetting nano-particles of materials much smaller than those of traditional powder bed processes

“The final product is much healthier,” adds XJet CEO Hanan Gothait as we look at a selection of finished parts.

Gothait is perhaps best known for his time as founder and CTO of Israel’s other high performing 3D printing company, Objet, before its merger with American firm Stratasys in 2012.

Choosing his words precisely, and with a big heap of modesty, Gothait describes the XJet’s technology as ‘simple’, while reserving most of his excitement for what the process means for the parts that come off the print bed.

Its zirconia ceramic parts are 99.95 per cent dense, while its metals characteristics, while yet not revealed in full, are set to be equally ‘high performance’ with regards to fatigue and stresses.

“Isotropic shrinkage is really important because usually 3D products shrink – Z-axis shrinks a lot, X and Y shrink less,” continues Gothait. “For us it’s all isotropic [shrinkage], so it’s much easier to control and calculate the results.”

At 99.95% dense, the Zirconia ceramic material has very desirable properties for engineers

Cavities and fine details can be created with little concern that they will be harmed due to the simple support-removal process. Unlike with other metals processes, as the soluble material is gently disintegrates in a water-based wash bath post print, before the part is fired in a kiln.

Additionally, the technology stands up better in terms of usability, with its closed cartridge materials and no need for inert gas infeed meaning it has fewer health and safety hurdles to clear compared with high power lasers and unstable metal powders.

This is all before we get to the notion of mixed material printing – something that is not an ‘if’ but a ‘when’ for XJet’s team of engineers.

The idea of parts being built with combined metals and ceramics in the near future opens up a new world of possibilities for designers from fields as diverse as medical implants to rocket engines.

There are several issues to overcome before multi-materials is a reality, but XJet has a plan.

The new alumina material is easier to work with than zirconia, opening up a new range of opportunities for industries like automotive

Building The Future

“The new AM Centre is a crucial part of our pursuit for wide-ranging multi-material printing,” says Gothait, explaining that the centre’s purpose will be to develop and demonstrate specialised applications, print test parts for a global customer base, and trial new metal and ceramic materials.

“We have very high goals and expectations for the AM Centre, and as such have placed our best resources here.”

Based on a science park in the quiet town of Rehovot, the weight constraints of all the hardware mean that the AMC is sandwiched on the ground floor between Mentor Graphics’ Israel offices upstairs and an underground car park below. As unassuming as the location is, this AM Centre is the base for cutting edge nano-particle jetting developments.

A collection of XJet 3D printers, we counted 8 units on show, sit inside the 8,000sq ft space humming away, restlessly printing sample parts in new metal and ceramic materials.

Despite all the activity – including wash stations, inspection tables and an office space – there are still allotted spaces for more machines to join the test farm, although it might be a squeeze.

The Carmel Systems are industrial in scale, with a mammoth cabinet containing the 500 x 280mm build platform and the technology needed to populate it.

It’s a print bed that will allow for sizeable builds, but at print speeds of 1 – 1.5mm per hour, the emphasis is on the better quality of parts rather than competing with mass manufacturing’s speed.

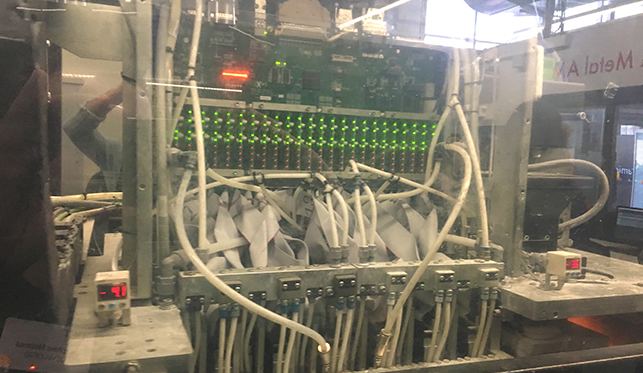

A look ‘under the hood’ reveals a complex system managing the print unit that runs on a gantry above the print bed. The build area will heat to nearly 300°C in order to evaporate the liquid ‘jacket’ of the nano-particles.

The undercarriage of the machine is dedicated to compute power, its materials, power source and jetting air pressure.

An inspection of the print unit is not for the fainthearted; boasting 24 printheads, each with 512 nozzles.

It is an ordered mass of wires, tubing and LEDs, not dissimilar to, although much bigger than, that of a Stratasys Connex 3D printer.

The view inside the build chamber

The bold and easy to read UI is highly viable on the side of the 3D printer

The user interface is much clearer to understand, with a giant colour touchscreen monitoring the build, materials levels, maintenance and servicing.

XJet’s use of a modified version of Autodesk’s Netfabb Ultimate software for managing the build set-up keeps support set-up and part orientation equally simplified.

Seeing the 3D printers in action and having the chance to inspect the parts under a microscope are reminders that this technology is at the cutting edge of what 3D printing can allow in terms of detail, materials, part density, and potentially mixed metals and ceramics.

XJet – Next Steps

Despite its status as a start-up, the term already seems outgrown by XJet.

The company already has over 50 multidisciplinary R&D specialists inhouse forming part of a team of over 100 staff, and has filed more than 60 registered and pending patents, while investors include a top venture capital firm Catalyst CEL and Autodesk.

The grand opening of its XJet Additive Manufacturing Centre – one of the biggest of its kind in the world – marks the solid progress of a company started in 2005, and bolstered by an experienced core team of ex-Objet employees.

Metal parts have been announced to launch in 2019

Already a new ceramic material, Alumina, has been launched as a result of testing at the AMC, offering a more versatile range of abilities and functions for engineering purposes.

It’s an outfit brimming with confidence, with the AM Centre inauguration following on less than a year on from the commercial launch of the Carmel AM system.

UK-based Carfulan was recently named as the first of XJet’s global distribution partners, and attended the AM Centre launch to catch a glimpse of their own first Carmel AM system, which has since been delivered to its headquarters on the outskirts of Derby.

Oerlikon, Syqe Medical and AB Universal already have installed machines, while more are awaiting to be shipped before the year is over.

At the end of 2018 XJet has already made a mark on the European market with its presence at the biggest Additive Manufacturing trade show, Formnext, while plans abound for further expansion as both a company and in terms of its technologies in 2019.

Everything about the company gives the impression that it is yet another start-up success to come out of Israel.