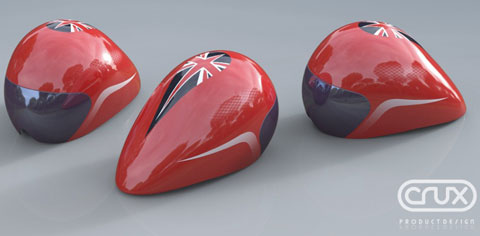

Team GB cycle helmets feature a dual shell design, comprising an inner shell, which fits closely to the athlete’s head, and an outer shell that is shaped for optimum performance

Crux Product Design, a Bristol-based design and engineering company, played an instrumental role in the development of the track and road cycling helmets that will be used by Team GB at the London Olympics.

The helmets were commissioned back in 2009 by Dr Scott Drawer — head of Research and Innovation at UK Sport and both Chris Boardman and Dr Matthew Parker from British Cycling. Crux was given a brief to develop an ergonomic and futuristic helmet through the use of novel materials and rapid manufacturing to allow bespoke fits for individual athletes.

Crux began by taking 3D laser scans of the heads of individual athletes with additive manufacturing methods used to turn 3D CAD models into rapid prototypes over night. The rapid prototypes were then physically used as part of the helmet fitting process; giving the athletes confidence that their helmet fit would be flawless.

Crux developed a dual shell design, comprising an inner shell, (the made-to-measure section) which fits closely to the athlete’s head and an outer shell that is shaped for optimum performance. In the middle lies an energy absorbing, safety material sandwiched between both shells.

Extensive testing found that aluminium honeycomb, often used within the aerospace industry, worked well as a material for the helmet core. Other materials used were polycarbonate, for the visor (as seen in riot shields) along with an iridium coating to ensure the riders vision isn’t impaired. The inner and outer helmet skins are made from ABS plastic.