Each year, the Autodesk faithful gather in Las Vegas to attend Autodesk University.

This year saw nearly 7,000 folks fly into a quiet, post thanksgiving Sin City, to find out where Autodesk is at and what’s coming down the proverbial pipe.

While in previous years, the event has focussed heavily on the AEC industry, this year was Manufacturing’s turn, and what a show the company put on.

From a set of individual conferences on the first day that spanned from the regeneration of Downtown Las Vegas into a manufacturing hub to John Cleese (yup. THAT John Cleese), Neil Gaiman and Syd Mead (who did the concept work for Blade Runner).

IDEO’s Beto Lopez “Play is one of the most generative ways of working together“

I spent most of the day in the i3D event. This saw Jen McCabe, Hardware Sourceress at the Downtown Project, address the crowd and talk how funding is changing the development of the hardware (read: physical products), just as it is the software industry.

Mark Hatch, CEO of TechShop, did his usual pitch that ran through the success brought about by easier access to manufacturing hardware (and they’re coming to the UK) and IDEO’s Beto Lopez talk about design is shifting and where some of the sweet spots are.

It was also a treat to see MakieLab’s Alice Taylor take the stage by storm and dispell some of the myths surrounding the 3D printing industry as well as detail how her company is actually doing something constructive with the technology.

The second day’s keynote that featured Penn and Teller followed quickly by a whirl wind tour through what’s on, Autodesk CTO, Jeff Kowalski’s mind and CEO, Carl Bass, talking about some of the interesting things that the companies manufacturing customers are doing: from bespoke musical instrument manufacture to robotics.

While the keynotes are one thing, the real reason folks descend on that most curious of cities, is to learn more about both their existing tools – either from classroom presentations or from hands-on learning – or to find out what’s coming down the pipe from the developers themselves.

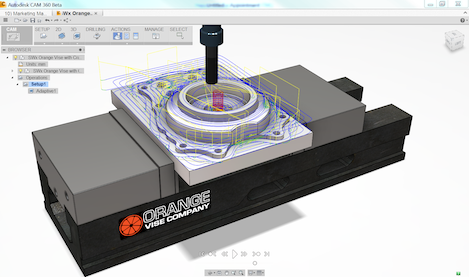

The big news for Autodesk University in the manufacturing space has to be the launch (if not release) of Autodesk CAM 360. In line with the other 360 products that cover 3D design (Fusion 360), PLM (PLM 360), simulation (SIM 360) and a few others, CAM 360 sees the company bring CAM to the cloud.

CAM: To the Cloud

Based on the technology it acquired with HSMWorks, CAM 360 looks to use the same platform as Fusion to create a new environment for programming CNC machines. While actual demonstrations were brief and the system isjust going to public beta test, we learned a few things.

The first is that the first ‘release’ will cover 2.5 axis machining – the most basic of all. It’ll be built into the same collaborative platform and interact with the other 360 services. That means that work is stored on the cloud, remains accessible from any machine and naturally, eminently sharable and available for collaboration around.

One thing that some might find a little curious is that while Autodesk makes much noise about the ‘infinite computing’ potential of the cloud (which is, frankly, nonsense when you think it through) and how the HSMWorks code is multi-threaded, the actual tool-path calculation is done locally, rather on a remote server.

SIM 360 does its number crunching in the cloud, why not CAM?

When you consider that they’re starting out with 2.5 axis, the benefits would be negligible once you factor in upload, download and processing – local is always going to be quicker in this instance. HSMWorks’ code is pretty efficient on today’s multi-core/multi-CPU machines and you’re always going to get a quicker calculation on this type of more simplistic tool-path by doing it locally, rather than using a cloud-solve.

That said, I’m sure that as the offering expands out, starts to encompass more complex machining tasks, then this might change. Complex surface-based machining, 4 and 5 axis tool-paths, are all highly compute heavy tasks and as such, makes a good candidates to take advantage of the parallel processing capability of a cloud solution.

Of course, you then have the issue of transferring of some pretty hairy data (just the geometry alone can be pushing the gigabyte order), but when you consider that calculation times for tool-paths in the tooling industry (think, a raster path across an entire mould’s surface), then the cloud has potential.

When a workflow is highly iterative (generate tool-path, inspect, simulate, tweak, recompute), but with compute times in the order of days, rather than hours, any speed up is beneficial. It’ll also mean that you’re offloading your computation from your local machine and can continue to work, rather than bringing the machine grinding to a halt while it computes out.

This is all assuming that the code used can take advantage of parallel computing.

So how’s it looking?

There are many issues to play out with CAM 360. Are machine shops ready for a cloud-based collaboration solution? Some of those relate to the technology.

Questions I’d be looking to answer are these: Can the code be made cluster aware as well as multi-threaded, so it makes sense to use a cloud-based solve, rather than a local one? Can the benefits of a cloud-solve be made usable, considering the iterative and often linear nature of tool path calculation? If you’re calculating tool-paths in parallel, how does it handle maintaining a stock model between separate operations?

Then there’s the business of running a machining facility: Can the lower cost attract them to take it on and adopt a different way of working (without reliance on local files)? Are machine shops comfortable with storing their data in the cloud as opposed to behind the firewall? Will their customers stand for it or will it happen under the radar?

One thing is for certain, it’ll be interesting to watch.

The beta is going live this week for CAM 360, so if you’re curious about how it looks, get signed up and have a play with it. It’s at a very embryonic stage, but worth investigation for any with even the most cursory interest in machining.

This hasn’t been tried before, but with the existing tech from HSMWorks and the forthcoming Delcam acquisition (of which there was no comment from the event at all as it’s still in progress), then Autodesk looks set to do some interesting things with the generation of NC code that will set it apart from almost everyone else on the market – which in and of itself, is always a risk.

The good news is that come the first quarter of next year, the company should (the Delcam deal isn’t complete until the shareholders have their vote) have access to one of the most comprehensive sets of traditional manufacturing and production related technologies on the market today.

This, of course, also means that it has access to a community of users spread across a massive array of industry sectors, niches and workflows, and from that, it can learn a great deal.

Autodesk 2.0

The way that Autodesk talks about manufacturing has changed – it is making the transition from talking about pure design tools (think; Digital Prototyping) to offering a solution set that covers everything.

From its support for the maker movement (which seems, in many respects, a curiously US centric one) through its professional digital design, engineering and simulation tools and into some, as many would put it, ‘proper’ manufacturing and production, the pieces are starting to stack up.

Autodesk University is also shifting. While 6 years ago, it was all about AutoCAD and the evangelists that surround it, today’s conference is dramatically different. In fact, it was nearly a day before I even saw a logo on a display screen, never mind a product mentioned.

When you consider that most conferences kick off with the vendor giving its roadmap plans and waxing lyrical about how well it’s doing in the market, it’s a change that’s for the best. The typical attendees at these events are already customers, do they really need the heavy sales pitch and corporate hoo-haa? Probably not.

They want to learn from both the vendor and their peers (from both the same industry sectors and others). Do they want an indication of future direction, a dose of confidence in their investment in a technology stack? Of course. But it doesn’t need to be rammed down their throats at every available opportunity.

Other vendors could learn a lot from Autodesk’s annual event and how to address its customers in this type of environment.