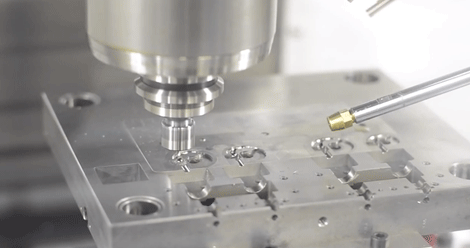

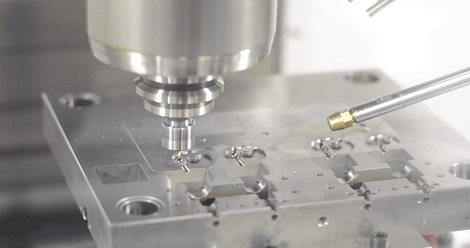

GAES CNC machines the intricate tooling for its bespoke products

At a time when the world is embracing 3D printing as the ‘bespoke’ manufacturing tool of choice, and in an industry where the vast majority of the products are 3D printed already, GAES has gone a different route.

The company, based in a five-storey office block in central Barcelona, uses its basement rapid CNC-machining facility to mill moulds and dies for the thousands of hearing aids it produces annually.

Its Microson brand produces six different types of hearing aid, and is continually developing the designs in order to make them smaller and less obtrusive.

The following video gives you the idea of the process involved, and a look at how its latest purchase, a Haas VF-2SS machining centre, speeds up the process.

//www.youtube.com/embed/-nxp5DbkJHo?list=PLIpdfqwvUhG9E4Ji4byO2l6sjHAUsUZNU