Of the large number of manufacturers that jumped into the desktop, entry level, FDM market a couple of years ago, Ultimaker has been one of the few breakout success stories.

With the release of the Ultimaker 3 (our write up is here), the company took one of its first steps to breaking away from its maker roots and starting to provide tools built for a more professional environment where consistency and repeatability are paramount.

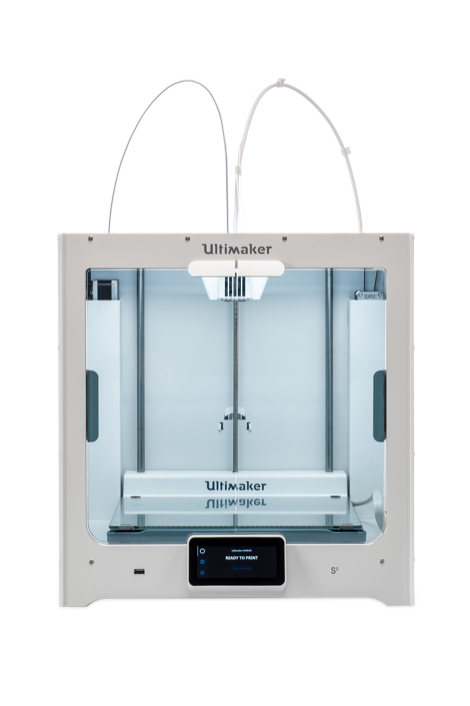

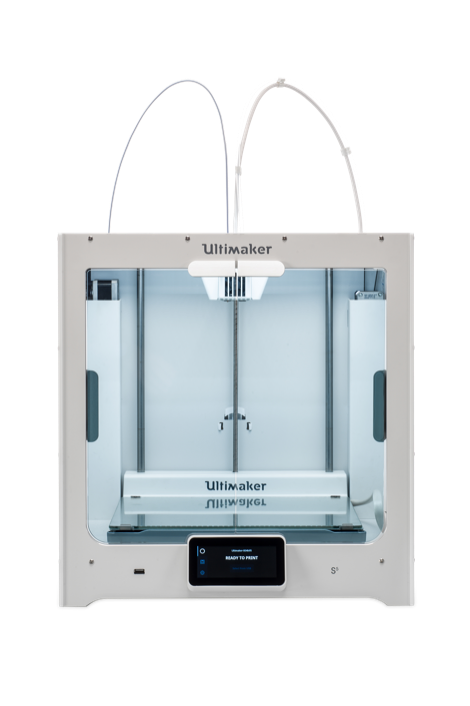

This week, Ultimaker has shown off its next step: the Ultimaker S5.

As you’ll notice, the S5 takes what the company has done with the ‘3’ models and improved on some key aspects.

It features the same swappable dual extrusion heads, but the S5 has a sizeable build volume of 330 x 240 x 300mm (compared to the 215 x 215 x 300 mm of the Ultimaker 3 extended) and a new touchscreen interface (compared to the LCD and scroll wheel of previous versions).

Under the hood, it has also added in a more rigid build platform, improved auto-levelling and for those large prints, the filament sensor that’ll pause your print if filament runs out. And it’s got front doors, too. That might sound like a small thing, but all together it gives you a better chance of a good, repeatable print in some more exotic materials like PC and ABS that could prove problematic on the Ultimaker 3s.

Alongside this, the S5 will also take advantage of the updates the company made to it’s Cura software environment that allows more remote management of networked machines and with the S5, takes this further with a new Ultimaker App that allows you to monitor and control your printer remotely.

If you’re curious, then the S5 will be available on May 15 this year direct or through some of Ultimaker’s resellers for €5,495.

Materials updates & partnerships

On the materials front, the S5 also sees the introduction of a new PLA material – similarly to Makerbot’s material of the same name, this a PLA derivative that has better impact strength and greater stiffness than common or garden PLA.

Alongside this, the company has also announced that a group of new partnerships with some serious names in materials development including DSM, BASF, DuPont Transportation & Advanced Polymers, Owens Corning, Mitsubishi, Henkel, Kuraray and Solvay and Clariant.

The goal is that Ultimaker will “provide software based on extensive research and development, and material knowledge to allow the collaborating companies to generate and maintain material profiles so that customers can reliably use the materials on Ultimaker 3D printers.”

What does that mean? If you go and buy a spool of Owens Corning’s Xstrand glass fibre filament, you’ll already have presets/profiles available in Ultimaker’s Cura software to help you get it printing right first time.