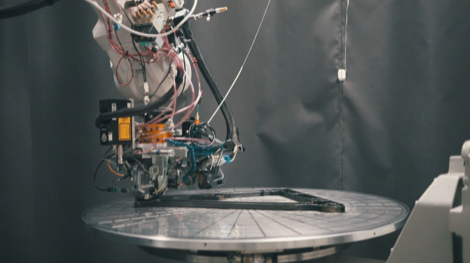

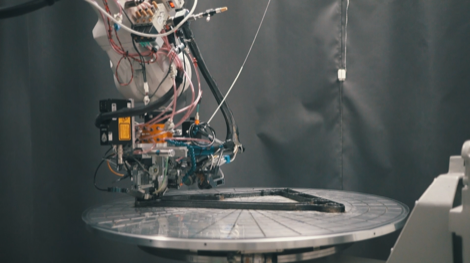

Arevo’s process combines continous fibre placement with PEEK/Nylon matrix, lasers and robotos

Arevo has come out of stealth with a series of announcements around the startup’s activity in the 3D printing/additive manufacturing space.

The company, founded by Hemant Bheda, uses a mixture of a commercial, off the shelf robotics, a continuous fibre and PEEK/Nylon matrix material and lasers to deposit material.

What’s interesting here is that unlike other fibre-focussed systems from the likes of Markforged, Arevo is looking to tackle how to build continuous fibre strengthened parts out of plane.

Also of interest is the use of laser to deposit the material, rather than an extrusion head – Arevo claims that it is achieving plastic composite parts built in an additive manner with one per cent porosity.

The gif below shows a nice frame byframe of how the mechanicals of the system work.

From speaking to founder and chairman Hemant Bheda it’s pretty clear that the company has some aggressive plans on how to brings its technology to market.

What’s key here, is that they see this as a software problem, rather than hardware – from the launch video, it looks like they’ve got their hardware straightened out – now it’s a question of building software that allows them to control how material is deposited and achieve the characteristics that the engineer needs.

This is where things get very interesting. Bheda spoke of software that first optimises the layup and build of the part to achieve the performance requirements, using a mix of FEA techniques.

The machine then monitors the build process and feeds back to a model that represents exactly how it’s built.

The digital twin is a common refrain these days, but this is truly fascinating: Design your part, using technology to optimise its construction, then use a ‘live’ model of the as-built, rather than the as modelled, in your further work.

Also around this news comes a new CEO. Arevo has brought on both Jim Miller, who oversaw Amazon’s expansion from books, music and video to full-range fulfillment capabilities as vice president of supply chain. Later, as vice president of worldwide operations at Google, Miller led the team that planned, built, deployed and operated the infrastructure that powers Google: search, YouTube, gmail, advertising and cloud businesses.

Of course, what 3D printing launch would be complete without a redesign of a bicycle – and Arevo are no different. The team worked with Studio West to develop and manufacture the ‘world’s first true 3D-printed commuter bike’.