The first commercialised SLA printer in Stratasys’ 30-year history, the V650 Flex marks a change in direction for the company with its open source materials

Leaning on the expertise of proprietary technology developed for its Direct Manufacturing arm, Stratasys has launched the V650 Flex – its first commercial stereolithography 3D printer in its 30-year history.

In a bid to ‘disrupt traditional stereolithography 3D Printing’, the V650 comes with a 20 x 20 x 23 inch build chamber, interchangeable resin vats for quick materials changeovers, and an opensource materials policy – another first in Stratasys’ history.

A partnership with DSM and its popular line of Somos stereolithography resins means that there are four ‘verified’ resins set for its launch in Q3 2019, although most SLA resins on the market are expected to work with the ‘Open Vat’ platform.

Chances are that if you’ve ordered an SLA part from Stratasys’ Direct Manufacturing service that it will have been produced on an inhouse version of the V650 3D printer.

Direct Manufacturing has 28 years of stereolithography experience, and this printer offers large-scale system power with a configurable environment for resin fine-tuning.

“This was designed for service bureau and large enterprise customers,” said Pat Carey, Stratasys senior VP of sales.

“It’s not a beautiful machine like an F123; it’s designed to be very accurate, to be high speed, and the footprint is extremely optimised. If you would imagine there’s a competitor selling a similar machine envelope, we can fit three of ours where two of theirs would fit.”

The V650 Flex design already boasts over 75,000 hours of runtime and more than 150,000 parts produced.

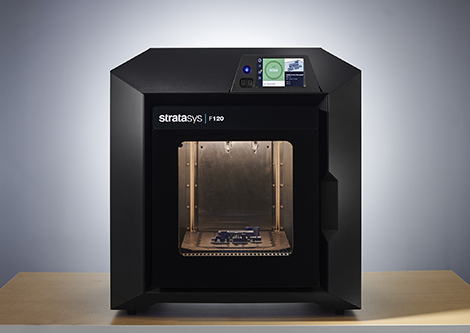

The F120 is the new baby of the Stratasys 3D printing portfolio, set for use in education and prototyping

Additionally, Stratasys has introduced a new entry model to its product portfolio, the F120, part of the F123 FDM 3D printer family, starting at $11,000.

This is significantly cheaper than Stratasys’ F170 model, let alone its top of the range Fortus FDM range. Stratasys explains that this is in order to make its FDM technology more accessible, with the machine expected to meet growing demand in the education market.

The price also serves to fill the gap between the F170 and the Stratasys-owned Makerbot Method.

Despite maintaining the 10 x 10 x 10 inch heated build chamber, the F120 eschews the cabinet and storage of an F170, placing its large filament spool containers on a nearby surface, making it more desktop friendly. Despite including ABS its materials range will not include ‘production part’ filaments such as the new F123 TPU material, which has made the F123 range so appealing to designers and engineers.

Available to order now, deliveries of the F120 will begin to arrive in July.