Based in North Wales, design consultancy Design Reality has spoken of how it has been able to offer a more end-to-end product development process by brining new Additive Manufacturing technology in-house.

It’s an interesting use story, not least because the move to AM production capability has helped Design Reality to attract several new customers since the installation, but also as it is utilising HP’s subscription-pricing for its 3D printing materials to pay for what it prints, as it prints, with a clear view of running costs.

The HP Jet Fusion 3D 4200, installed in October 2018, allows Design Reality to offer customers an end-to-end solution for prototyping and production needs, while it can monitor usage and costs via a digital dashboard, providing insights into print job usage and associated costs to stay onto of those pesky overheads.

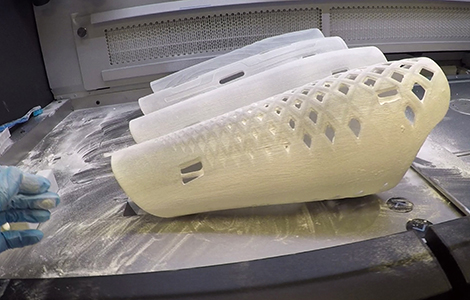

The machine itself is doing itself justice with the durability of the models, with robust, practical products such as construction hats and prosthetic limbs a key earner for Design Reality, with the HP Nylon 12 material allowing them to optimise cost and part quality.

“We want to leverage any advantage we can to improve product development quality, performance and speed of delivery,” said Design Reality owner and design director Graham Wilson.

“The technology offered in the HP Multi jet Fusion HP 3D 4200 enables reliable prototyping and additive manufacturing, providing quality products into the hands of our clients, faster and at a lower cost.

“Our clients no longer have to wait for conventional tooling and manufacturing processes, and the investment that is associated with it.”