Arevo continues to focus its 3D printing technology on the world of high-level cycling, announcing its work to produce a new set of composite wheels and a new e-bike frame, all featuring the ‘Arevo DNA AM process’.

Explaining this as its own unique technology, it is said to feature patented software algorithms that enable generative design techniques, free-motion robotics for ‘True 3D’ construction, and direct energy deposition for virtually void free construction, all optimised for anisotropic composite materials.

Arevo says this process takes the design and final manufacture of a bike frame down from 18 months to just a few days, leading to a significant reduction in product development costs.

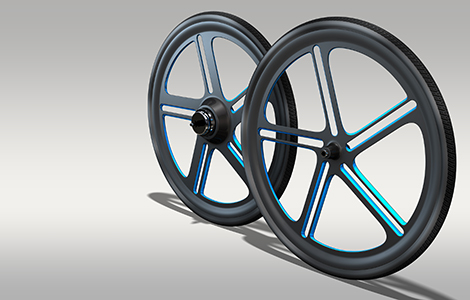

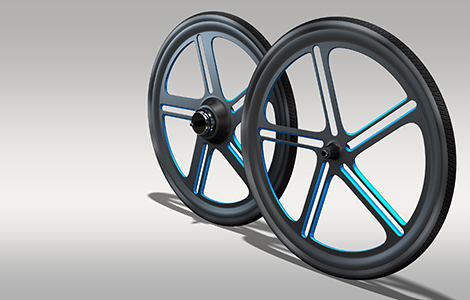

The world’s first 3D printed thermoplastic rim was designed by Eurobike Gold Award-winning industrial designer Bill Stephens of StudioWest, and will go on display at Eurobike 2019 in Germany this September.

The company will also display the world’s first 3D-printed carbon fibre unibody production bike frame in the stand of manufacturing partner Oechsler AG.