Stratasys and BAE Systems have announced that they will further strengthen their relationship around emerging additive manufacturing solutions within its Land, Maritime and Air Sectors.

The collaboration means global 3D printing leader Stratasys will provide the defence, security, and aerospace giant with increased access to new materials and production technologies currently under development or planned by the company.

BAE Systems has been a Stratasys customer since 2006, and currently deploys a blend of the company’s PolyJet and FDM-based additive manufacturing technologies. These include a battery of F900 Production 3D Printers, installed at the company’s advanced manufacturing facility in Samlesbury, England.

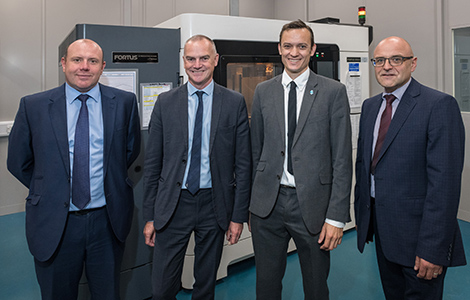

Pictured alongside the Stratasys F900 3D Printer are (from left) – Ian Barton, Head of Strategy & Investment Planning, BAE Systems; Andrew Schofield, Head of Manufacturing & Materials Engineering, BAE Systems; Yann Rageul, Head of Strategic Accounts for EMEA at Stratasys; and Simon Whitaker, Technology Operations Manager at BAE Systems

Stratasys hopes to benefit from dedicated insight and guidance into specific existing and future needs demanded by the major aerospace and defence manufacturer. This, Stratasys believes, will be invaluable for steering future R&D programmes and the advancement of next-generation additive manufacturing technologies.

Commenting on the collaboration, Dave Holmes, Manufacturing Director, BAE Systems Air, said, “We’re delighted to bolster our relationship with such an innovative partner as Stratasys. Already integrated across our production operations, Stratasys’ technology will continue to be vital in addressing and solving our current and future manufacturing challenges.”

Yann Rageul, Head of Strategic Accounts for EMEA at Stratasys, said, “Stratasys’ close cooperation and knowledge-share with strategic customers like BAE Systems is paramount to ensuring we continue to stay ahead of the curve when it comes to developing and delivering additive manufacturing solutions that meet exacting application requirements within key industries.

“We look forward to strengthening our ties and working even more closely with BAE Systems to help realize their short and long-term manufacturing objectives,” he adds.