The winners of the 2020 Altair Enlighten Awards have been announced, with the winners of the four categories recognising commercial automotive light-weighting achievements and technologies.

Presented jointly with the Center for Automotive Research, the 8th Annual Enlighten Awards acknowledge some of the world’s best initiatives to reduce vehicle weight and meet emissions targets, inspiring breakthrough advancements that push the industry towards a more sustainable future.

“As we sit at the crossroads of science, engineering, art, and design, creating a more sustainable future is the essence of Altair as we are a pioneer in light-weighting technologies and methodologies,” said Altair CEO James Scapa.

“I am proud to see that the Altair Enlighten Awards have become a sought-after recognition that acknowledges the world’s greatest automotive light-weighting innovations, while inspiring interest from industries, engineers, policymakers, educators, students, and the public.”

The 2020 Altair Enlighten Awards Winners

Full Vehicle winner:

Harley Davidson Motor Company utilised electrification to improve energy capacity of its Livewire electric motorcycle by 90 per cent, while increasing the ratio of energy capacity to vehicle mass by 60 per cent.

In addition to further improvements, this initiative established mass and stiffness design and optimisation practices for future motorcycle programs.

Module winner:

An industry first, Toyota created a free standing two occupant injection molded back-frame with no moulded reinforcement for the 2021 Sienna.

It consolidated 15 components to one part with one injection, driving down costs by 15 per cent, reducing mass by 30 per cent and improving safety performance by two times.

Enabling Technology winner:

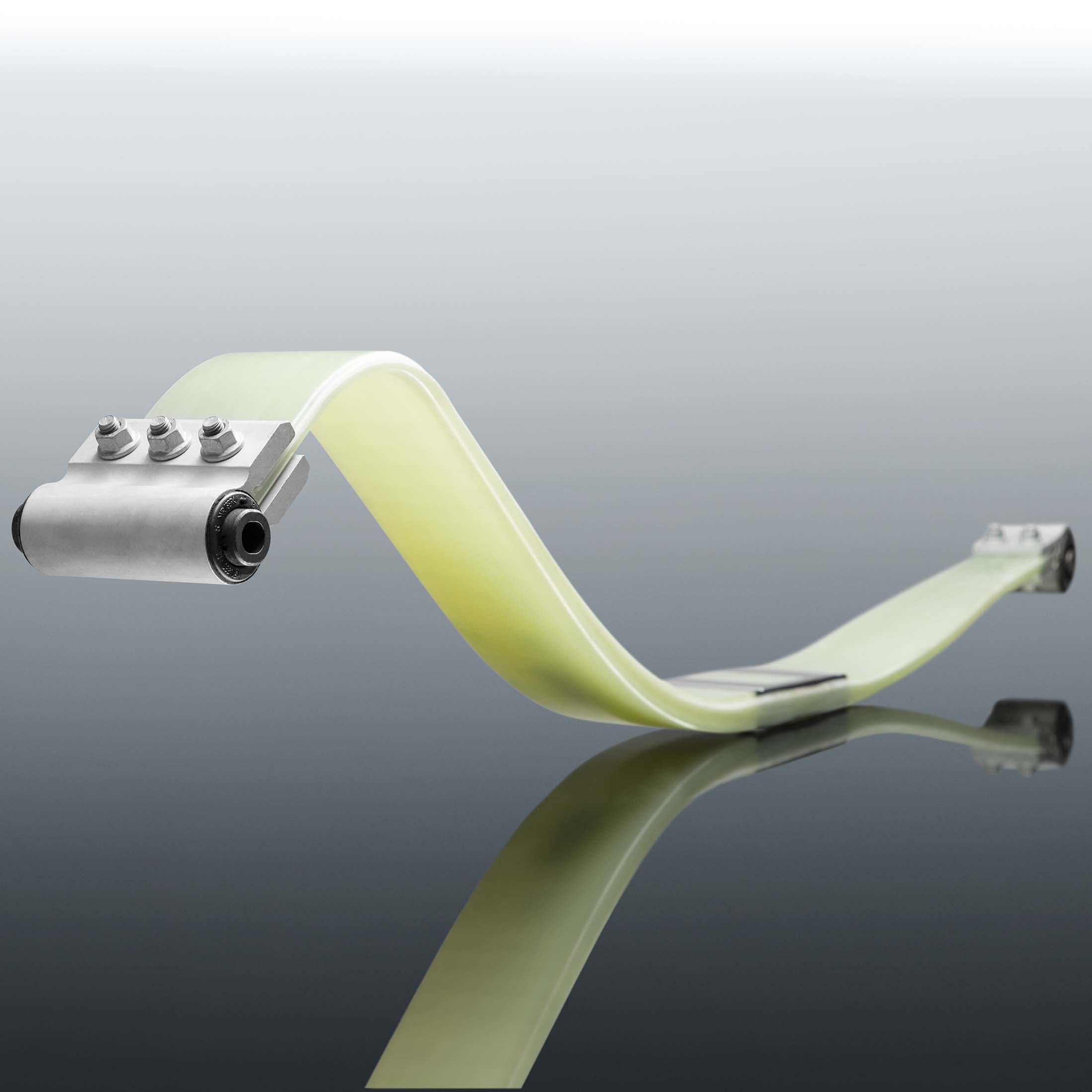

Mubea developed a glass fibre-reinforced polymer Tension Leaf Spring with weight savings of up to 75 per cent compared to a standard multi-layer steel spring.

The company used a scripted and automated workflow that begins from a parametrised spring model in which all spring parameters can be adapted.

Future of Lightweighting winner:

Marelli developed a new advanced sheet compression moulded suspension steering knuckle that ensures a 25 per cent mass savings compared to the aluminium version used on the Jeep Compass and a 50 per cent savings compared to the cast iron version.