A new pre-processing simulation software, Amphyon, has been unveiled as a joint project from EOS and Additive Works to highlight and optimise possible problematic areas of metals 3D printing.

Simulating the build process before it takes place, shape accuracy, surface quality as well as build productivity and stability can be increased by Amphyon, saving time and costs in developing additively manufactured components.

The goal of the joint venture is for both companies to develop further enhancements for Amphyon, before integrating the assessment, simulation and support modules into EOSPrint 2, EOS’ job and process management software.

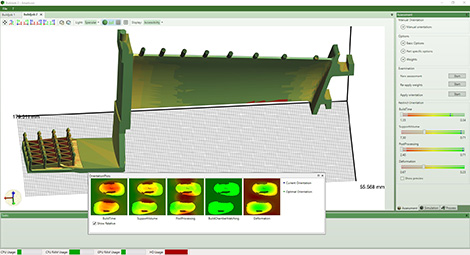

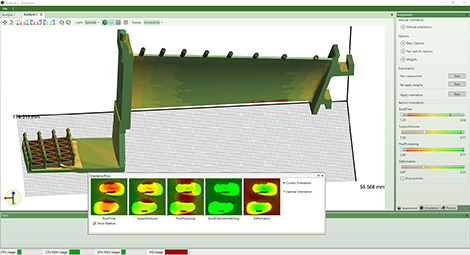

Amphyon orients all steps along the ‘ASAP’ principle (Assessment –Simulation – Adaption – Process), a new workflow for Direct Metal Laser Sintering job preparation, consisting of a couple of different software modules, Amphyon especially addresses the application areas part assessment, support optimisation and process simulation.

On the assessment stage, an examiner module evaluates the geometry of the part and assesses all possible build-up orientations.

Doing this manually can be challenging as the ideal orientation always depends on the application in terms of build time, support volume, post processing efforts and part deformation.

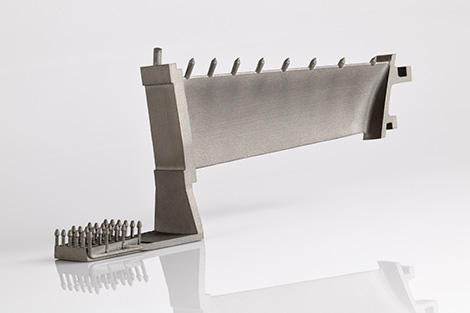

On the simulation stage, there are two modules available: The Support module, which is in a beta phase at present, and the Mechanical Process Simulation (MPS) module. With the Support module, optimised support structures can be generated automatically.

These structures support the part on the build platform and define the process results.

Amphyon’s optimisation routines adapt the support perforation as well as the interfaces between part and support based on the calculated process loads – not only the time and costs of manual support generation can be saved, but also support material can be saved and process stability is increased, avoiding costly build fails.

The MPS module offers users a way to simulate process mechanics and to calculate distortions, which can be compensated by the software by exporting and building a ‘pre-deformed’ STL file.

Key EOS metal materials are integrated into Amphyon software and are calibrated with regard to their material properties, with the goal to calibrate and implement all metal materials from EOS in the future.

Additive Works CEO Dr. Nils Keller, said: “Although the AM-technology itself is very mature, especially for unexperienced users it can be difficult to predict if a part will be 3D printed as expected.

“Using simulation software is standard when it comes to conventional manufacturing methods. With Amphyon, simulation now also becomes a solution for additive manufacturing, underlining the increased use and changing requirements of industrial 3D printing for serial production.”