ZSK expects its new Tailored Fibre Placement to increase the use of composites in industry verticals such as automotive

German supplier ZSK has launched a series of innovations for Tailored Fibre Placement (TFP), an interesting carbon composite manufacturing technique, which offers to dramatically cuts costs and offer new possibilities for improved component design.

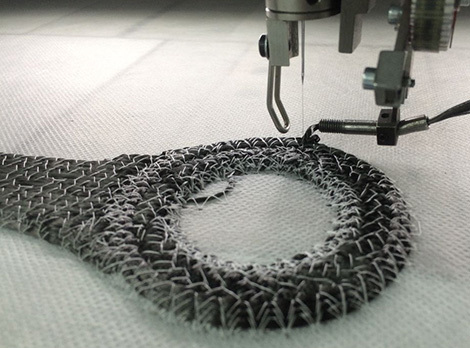

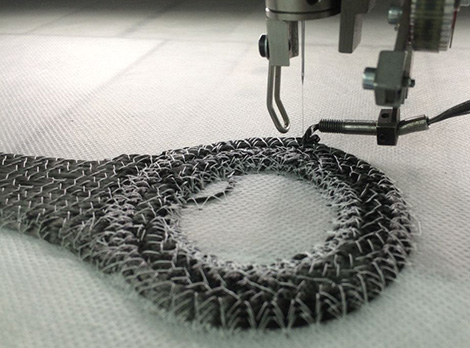

Unlike the conventional approach of weaving the fibres of a composite into a perpendicular arrangement then cutting the fabric to the required shape, TFP arranges the functional fibres in bundles exactly where they are most needed for structural performance and stitches them into position on a compatible base layer.

ZSK commits that this gives ‘absolute freedom of positioning’, allowing fibres to be placed in the optimum directions to carry the loads, ensures that they do not move during processing, and cuts fibre wastage to just three per cent instead of the usual 30-70 per cent on a typical automotive component.

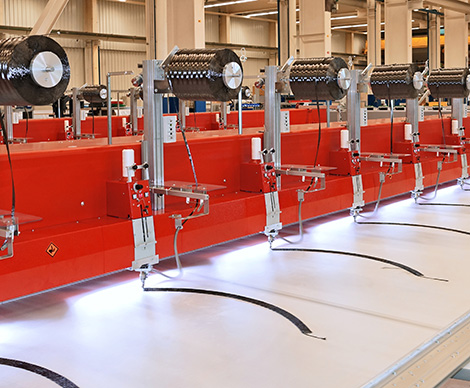

Benefits of the new ZSK ZCW0800 8 head TFP machine include greater strength and materials variation

ZSK’s machines are able use TFP to create 3D pre-forms that match the finished shape of a typical automotive part.

Patented innovations to the machine speed up the deposition of fibres, increase versatility and streamline the design process – while the Fibre Supply Unit that doubles the deposition rate also allows simultaneous deposition of different fibres and automatic switching between different materials.

ZSK adds that its ‘advanced design code’ also ensures perfect repetition of results, even controlling zig-zag stitching automatically.

“The demand for lightweight materials, to improve CO2 emissions and product performance as vehicles become heavier and more complex, has never been greater but the cost of composite manufacture has remained unaffordable in all but the most specialist niche applications,” explained Melanie Hoerr, manager for technical embroidery at ZSK.

“Our approach using TFP breaks through that barrier by eliminating most of the manual processing and waste of conventional composite manufacture, while increasing design freedom and improving quality control.”

In addition to optical and wire components, TFP can incorporate polymers commingled with carbon fibre to be melted later during moulding to form the matrix, avoiding the need for a resin filler, accelerating the production of complex parts and improving the resin-to-fibre distribution, especially in the extremities of the mould.

Current difficulties with end-of-life recycling of composites could be largely overcome by choosing appropriate polymers for re-melting to simplify separation during end of life recycling.