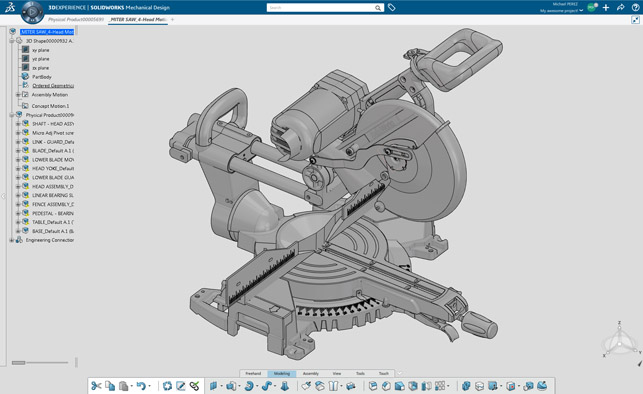

SolidWorks Product Designer – bringing a more comprehensive toolset for design and documentation for SolidWorks users looking to jump on the 3DExperience platform

For the second year running, the SolidWorks World event rolled into downtown Los Angeles in February and, once again, 5,000 or more of the faithful gathered to learn what the future holds for their tool of choice, to learn from their peers and to find new inspiration. For 20 years now, SolidWorks World has become the Mecca for a mix of users, development and sales staff as well as partners, resellers and a wider community.

While the event centres on learning for the SolidWorks community and the exchange of ideas and networking, it has also become the predominant platform that Dassault uses to pitch its vision for the future of its products, both in the near and the long term.

During those all important keynotes each morning, we get to learn where the great minds at the company are looking to the future, as well as learning what some of its customers have been up to. On the latter front, this year did not disappoint.

The Ring Brothers show off their 1,000 hp+ beast

Walking assistance for those with partial mobility problems and hemiplegia

SolidWorks – The remarkable & the ridiculous

For this year’s keynotes, once we’d slogged through the software executive keynotes (which we’ll get onto shortly), the attendant crowd got to see some amazing uses of creative and technological thinking mixed in with a little use of SolidWorks.

There were three stand out presentations for me this year. The first has to be Dr. Kyoungchul (KC) Kong of SG Robotics. KC’s team has developed two products designed to assist with rehabilitation of the mobility-impaired and paralysed. The first, the WalkOn suit, is a wearable robot designed for people with completely paralysed legs, while the other, Angelegs, is designed to help people with partially impaired walking ability.

The second stand out presentation was Neri Oxman from MIT Media Lab. If you’ve ever seen Neri speak before, you’ll already know that the process is, to use a grossly overused phrase, a journey. You begin with confusion, wondering what she’s talking about as she expounds on the use of cell-level growth inside 3D printed forms, death masks and much more.

Then you move into the realisation that the passion she exhibits is linked to exploring the future of how things are manufactured and constructed. Then you recognise that what you’re seeing is one of the finest minds of recent years, exploring the potential for a wide range of technologies to influence how we live.

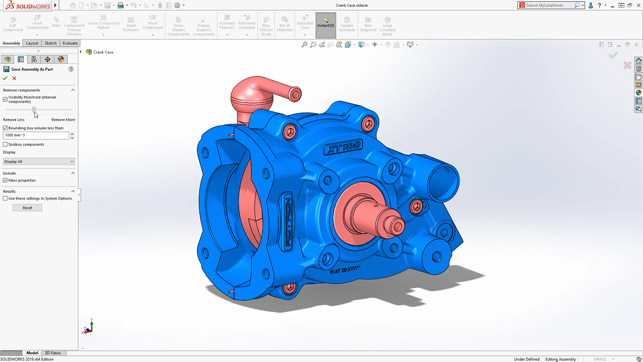

The last stand out presentation was the Ring Brothers and their custom car builds. Ever wondered what three quarters of a million dollars will get you in terms of an American muscle car? The answer is a 1,036 horsepower 1972 Amc Javelin that’s been rebuilt from the rubber upwards. The brothers talked about how they rely on SolidWorks combined with their own in-house laser scanning setup, machining and carbon fibre workshop.

MIT Media Lab’s legendary Dr. Neri Oxman

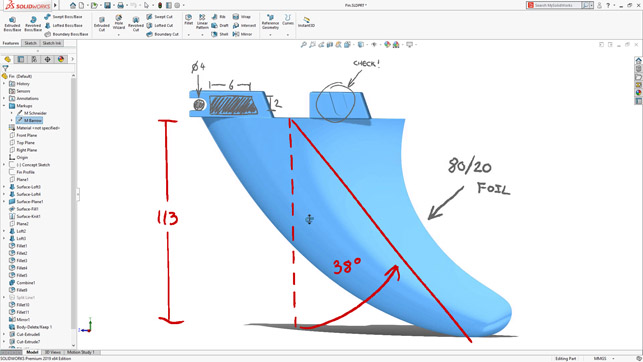

Tarso Marques talks simulation and optimisation for his custom bike builds

SolidWorks – New product announcements

So let’s talk about what SolidWorks has announced at this event and how it dovetails (or doesn’t) with what the company has announced previously. Let’s start with what the current product range looks like.

There were a great deal of announcements that focussed on tools or service add-ons that were built on top of the 3DExperience platform but which interacted with SolidWorks, rather than new technology for the product itself.

A good example are the 3DExperience Marketplace and Part Supply services. This sees Dassault roll out both part manufacturing and standard part sourcing tools that connect the user with service and part providers. What’s interesting here is that Dassault has done a pretty good job of bringing in a good number of partners for both.

While the Marketplace follows the same core concepts as the likes of 3DHubs or Xometry, it does so with a larger backbone of data handling for 3D geometry (rather than pure part file upload).

The selection of partners is impressive – bringing together some of the big names in both machined and additive part manufacture (Protolabs, Stratasys, 3D Systems) with smaller, lesser known vendors.

The Part Supply service differs in that there’s a much richer set of suppliers to work with and Dassault has pulled together an impressive set of partners here too. Helped, I suspect, by the investment already made in 3Dcontentcentral that has been around for a decade or more.

Then there is, of course, Desktop SolidWorks and its associated data management solution, SolidWorks Manage, which runs on a server client basis and replaces all of the data management tools that the company has introduced before hand. This is where things are now for the vast majority of users.

Then we have the new products – often referred to as SolidWorks V6, but we’ll try to get away from that so we’re all clear on what the score is. To get that picture crystal clear, we need to understand that, in the future, Dassault sees everything running on its 3DExperience platform.

This is where much of the confusion arises. Dassault has been using the term 3DExperience for a couple of years and now it’s both a product platform and a branding/marketing term, which does nothing to help clear up the confusion.

In terms of product, 3DExperience is an amalgamation of Catia, Enovia, Simulia and much more.

So think of it like this. Rather than using Desktop SolidWorks and a client/server data management system, Dassault’s next generation SolidWorks products will run on the 3DExperience platform. That platform will provide geometric modelling functions, drawing functions, data management functions and much more.

This much is pretty clear and has been the case for a few years. What has changed is how Dassault is looking to add the tools that designers and engineers need on top of that platform.

Dassault’s new product aimed at those looking for fuller featured, SolidWorks-like tools on its 3DExperience platform

The new hotness

While SolidWorks has experimented with the likes of SolidWorks Mechanical Conceptual and SolidWorks Industrial Designer in the last few years, these haven’t seen light of day as yet in any great numbers.

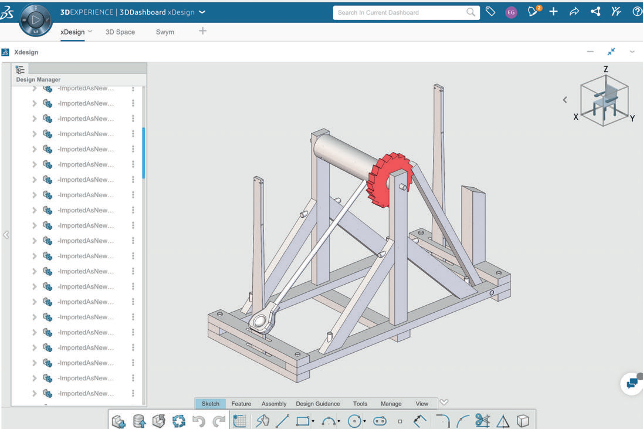

We know of users that have been trying to just get demonstrations of these tools for years. Then, in the last few years, the company made another announcement – SolidWorks xDesign.

This was a new approach, bringing a much stripped back set of tools in a browser-based guide. No install, no set-up required. You simply log-in and use the product. The data is stored on your 3Dexperience and instantly managed and available.

The problem with xDesign is that very few users have seen it. In fact, SolidWorks confirmed the exact number at the event – less than 30 have used this product in the wild.

It will add another 30 in the coming months and is looking to open access to a couple of thousand of application engineers within its VAR community in the next year or so.

Alongside this, the company has also announced a brand new product for 2018 (brace yourself): Dassault Systèmes SolidWorks Product Designer. While details are scant, this is another CAD tool that has been built on the 3DExperience platform. It’s not browser based, but uses a locally installed application that communicates with the 3DExperience data management platform on the cloud.

From speaking to Kishore Boyalakuntla, vice president, product portfolio management and brand user experience leader at SolidWorks, who heads up development of these products, this is a product that’s intended to bridge the gap between the users that want the same experience as SolidWorks, but are looking to use the 3DExperience platform for their company’s data management and collaboration backbone.

As we said, there was no formal demo of this product, but it was clear from what was shown that Product Designer is a more fully fledged product, covering part, assembly, sheet metal and drawing creation, built directly on the 3DExperience platform.

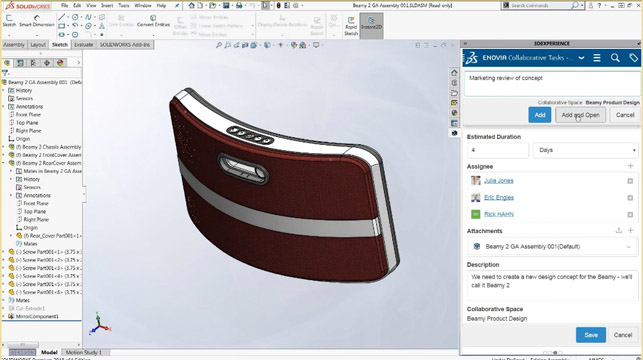

Then, to further compound the confusion, the company also announced the snappily titled “SolidWorks 3DExperience PLM Services”. This is the route you’ll take if you want to retain your Desktop SolidWorks that you have now, but want to use 3DExperience/Enovia platform.

These PLM services will give you direct access to Enovia as your data management platform from within Desktop SolidWorks.

PLM Services allows you to connect directly to 3DExperience/Enovia from desktop SolidWork

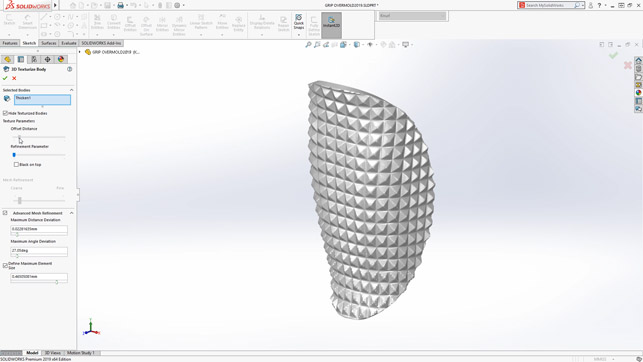

The new Texturise comment in appearances allows you to model complex surface textures quickly using a bump map

Updates coming to SolidWorks 2019

Alongside future products, SolidWorks World is also a fantastic place to learn about what the company has coming in the more immediate time frame.

While on the previous page, we’ve detailed what’s coming and will be available soon in terms of additive manufacturing and 3D printing, there’s a whole lot more to be gleaned from the event.

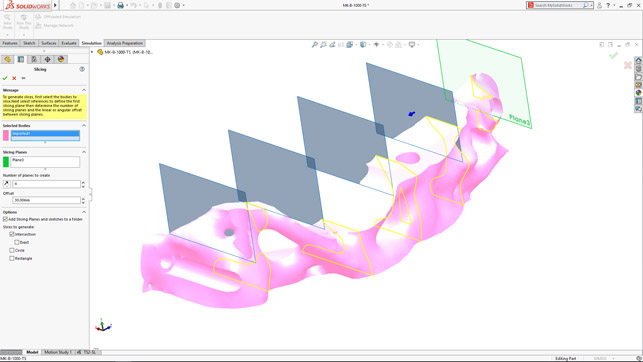

If there’s a trend that’s identifiable, it’s that the SolidWorks organisation is taking the use of mesh-based geometry more seriously than it has done in the past. While the 2018 release saw meshes made equal citizens in terms of geometry inside the system alongside more traditional solid and surface entity types, you’ll see more expansion on what can be done.

There was a particular demo showing that you’ll be able to create textured surfaces more easily – not just a visual representation (as you can already do with appearances), but to hard model those features into your model’s surface using the “Texturize” operation.

Something that would previously have required the use of a plug-in or, indeed, another system entirely.

Related to this is the ability to quickly extract sketch-based sections from meshes – something that’s going to prove useful for those working with both reverse engineered data as well as data resulting from topology optimisaiton.

This combined with the plug-in that 3D Systems has released, should make working with mesh-based forms easier. Though, as you start to add more of these heavy data forms to your models, you’ll see a performance hit. This was something we asked Kishore about and it appears that there’s some work planned to make the system more usable with such data types.

Other notable updates include greater ability to document and mark-up data using pen-based computing devices. These will appear in the Markups folder in your feature history, remaining available to those that need them (including yourself in six month’s time).

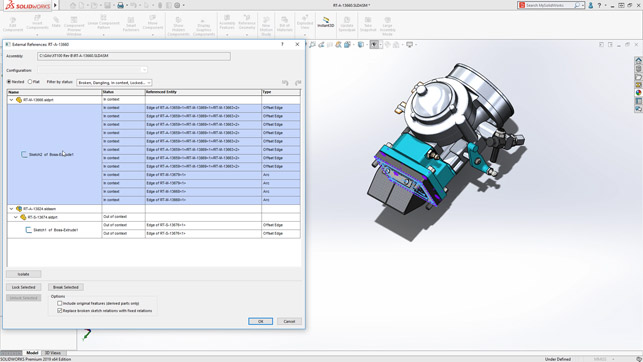

There also looks to be a tonne of work being done on higher level modelling methodologies and correcting some of the bad behaviour of the system. The first is related to multi-body modelling, something that has gained ground in some areas, primarily where a top down approach is required, but with complex geometry that’s ‘split’ into smaller components later on in the modelling process.

These new tools better handle the creation of assemblies as multi-body parts (useful for communicating data with customers without divulging IP) or creating lighter weight representations of complex assemblies. The system will also better handle assemblies with external references, something that’s a bugbear for many CAD managers.

Another interesting snippet to come out of the event was that SolidWorks is working on some of the visualisation aspects of the system too.

Firstly, there’s been the addition of Nvidia’s AI and heavily GPU driven de-noising tool to SolidWorks Vizualise. This gives you dramatically quicker rendered images by removing the noise found early on in progressive renderers automatically. Perhaps more interestingly for those with a fascination with VR, is that the development team is working on a way to have your VR headset enabled during your main SolidWorks session.

Multi-body modelling and external reference handling are going to get attention in 2019

A conclusion of sorts

Attending SolidWorks World these days is an interesting activity – particularly as I’ve been going to these things (with a few years off in latter years) for nearly two decades now. I was at the first one in Palm Springs in 1999 where it was run by the founding team and had a comparatively small handful of customers spread around a pretty compact complex.

Fast forward to 2018 and you’ve got a few thousand or more users, resellers and partners filling up a good portion of Los Angeles’ convention centre for four days. What has also changed is the presentation of the product.

The opening day, for many, is the one they have to sit through to get to the good stuff . For the first general session we saw a barrage of talk around 3DExperience and the Experience economy, and, frankly, a lot of announcements and product demonstrations that would be more suitable to a Catia or Enovia user event than this one. This is perhaps part of the problem.

New mesh sectioning tools will come in handy for those using reverse engineering workflows and topology optimisation

Pen based input is perfect for markups and documentation — from 2019 they’ll be stored in your Markups folder

Dassault clearly wants to move the SolidWorks faithful to the 3DExperience platform, to have them managing their data in Enovia and using 3D design and engineering tools that’s built on their own platform. There are, I’m sure, many valid reasons for that . It’s one of the most advanced toolsets in the world for the design of highly complex products, after all.

But does the average SolidWorks using organisation want to go that far? Are they content with their current toolset? From our discussions and chats at the event, they most definitely are. Do they want to see where the future of that toolset is going in the next 20 years (which is the period Dassault references when talking about Desktop SolidWorks)? Of course, they do. Do they want to see what their peers are doing with it? Absolutely.

This is one of the most inspiring parts of any user event – finding out that the same tools you use day in/day out are the same used to build robotic legs that help people walk again, create the futuristic environments we see in the movies or used at the cutting edge of super sonic air travel.

What doesn’t inspire you is spending two hours being told of products that no one has seen, that no one can buy and no one is likely to see in any great depth in the next few years and whose direction of development might change at any point between now and whenever they might get a general release.

The current user interface for SolidWorks xDesign — the cloud-based modelling system that Dassault has had in the works for a number of years

Dassault initially talked about its next generation products back in 2008. The core message hasn’t changed. The future of SolidWorks will be on Dassault’s 3DExperience platform and will bring a closer alignment between Dassault’s higher-end product set and the mainstream, volume market that is SolidWorks. This is the constant and it hasn’t changed at all in the preceding eight years or so.

But, at the same time, there’s been no progress either. We’ve seen the likes of Mechanical Conceptual, Industrial Designer, xDesign and the new Product Designer talked about, demonstrated and launched on stage at SolidWorks World. Have we seen it out there in the wild? No. Have we seen users talking about it in any great numbers? No.

Dassault has made a great deal of noise about how it sees the future of the SolidWorks business, but has yet to deliver on that future promise in any meaningful way. Now, eight years on, we have the company talking with delight about how 30 or so folks have seen its cloud and browser-based xDesign system. That they’re looking to expand that with another 30 users and perhaps 2,000 application engineers at resellers by the end of this year.

At the same time, the Solidworks community is one that’s invested in an entirely different set of products, one that they’ve built up a huge database of knowledge, experience and best practice around. Estimates are that there are half a million active, commercial users of SolidWorks out there.

Half a million folks doing meaningful work that deserves more attention. I think they deserve better from their annual user event. That meaningful work should come first on stage, not a product pitch. It’s a question of respect for your audience and for your customers.

Other than that, it’s interesting that SolidWorks is also looking to address some of the coming challenges in the design and engineering world. Its realisation that the mesh-based format is becoming increasingly important and workflows are being developed to address this, both natively in the tool and with third parties.

There’s also a drive to solve some of the age old problems that traditional CAD users have faced for decades (multi-body working, external references etc.).

Additive manufacturing @ SolidWorks World 2018

This year saw a large concentration of 3D printing related announcements that came to fruition from SolidWorks working with a range of different vendors, both brand new and well established, so we thought we’d pick our top five to highlight from the event.

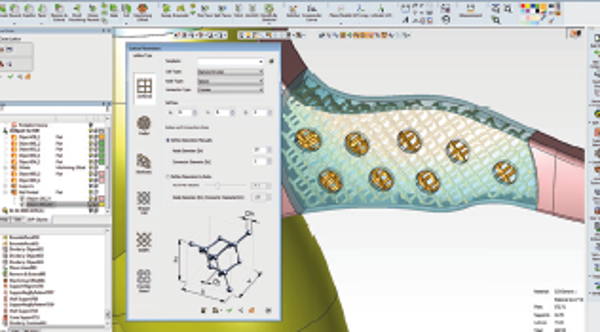

#1: 3D Systems is building lattice design and light weighting tools into SolidWorks

At present, SolidWorks doesn’t have much in the way of lattice design and light weighting tools for additive manufacturing.

To help solve this, 3D Systems has launched a plug-in for the system that brings a lot of its best practices and knowledge from its standalone print preparation system, 3D Expert, directly into SolidWorks.

While the system offers a pretty solid base level of functionality across the board for free, there’s also room to upgrade your capabilities with a cost option. It’s available now in your subscription centre.

#2: Desktop Metal is launching live parts via SolidWorks’ VAR Channel

Desktop Metal, known for launching its dual stream approach to metal part production, has launched Live Parts.

This is a cloud-based GPU driven system that uses cell growth algorithms to optimise the form of parts by simulating natural loading conditions and phenomena.

There’s a direct link to SolidWorks geometry from the system ready to go, so have a little play with it while it’s in beta.

#3: SolidWorks launches 3D printing certification

SolidWorks’ certification program has been a popular endeavour with many employers using it as a benchmark for how experienced or, at least, how comfortable with the system a user is. The users themselves see their certification as a badge of honour.

While the certification exams have tended to be application specific, there are instances where things have opened up – and the new 3D printing generalist certification should prove useful, even if just as a learning experience for those that take it.

#4: Rize adds SolidWorks integration capabilities

Rize announced that it has built a tighter integration between its machines and SolidWorks, with a new add-on that allows users to simply select Rize 3D Print from the SolidWorks Tools menu.

The Rize add-in automatically transfers files from SolidWorks to the Rize slicing software without the need to export and import files. Users can download the complimentary add-in from the Rize website.

#5: Voxels are the future according to HP

As we move away from single material builds (or rather, single material type of varying colours or hardnesses), we’re starting to see hardware vendors explore the potential for the voxel level control of materials. HP is one such company, which has a benefit in that its MJM machines are able to control things at this finer level.

While no one has actually shipped a machine that’s capable of doing this yet with anything other than colour and elasticity of a polymer, it does raise an interesting design problem.

If we’re truly able to fine tune the performance and characteristics of our materials at a voxel level, we’re also going to need a set of tools that allow us to define that information – and none of today’s design and engineering software systems can.

At the event, HP sat down with SolidWorks head honcho, Gian Paolo Bassi, to commit to exploring this is in the future, but without any commitments of time frame.

We discover what Dassault Systèmes SolidWorks is up to next

Default