Piaggio Fast Forward’s 60,000 square foot office and workshop

Headquartered in Boston’s thriving Cambridge district, Piaggio Fast Forward (PFF) was founded in 2015 to create lightweight, intelligent and autonomous mobility solutions for people and goods.

The company is a subsidiary of the Italian transportation legend Piaggio Group, which has remained a world leader in light mobility for 130 years by combining advanced engineering with design that empowers and delights. Arguably its best known product is the Vespa, a true global design icon that brought mobility to the masses, making movement effortless for men and women navigating everything from the tight spaces of historical cities to rural back roads.

Rossitza Kotelova, senior designer at Piaggio Fast Forward and Amos Ambler, mechanical engineer at Piaggio Fast Forward

Mobility for the 21st century

With its PFF initiative, the company has brought together a team of researchers, designers and engineers to pioneer the intelligent movement of people and goods for the 21st Century. It wants to utilise the constant strides being made in machine intelligence, autonomy, and ubiquitous networks to help people move better, further, faster and more enjoyably around our cities.

The plan is to hatch new varieties of smart vehicles and robots, which are larger than aerial drones but smaller than cars and trucks, that travel behind, beside, and beneath people on the move.

The first of these is a two-wheeled personal robot called Gita, which is able to carry 40lbs worth of cargo and move at speeds up to 22mph.

That is its top speed, the intention is for Gita to trail you at a slower pace through the city, carrying your goods, whether that be shopping or work tools, allowing you to be hands free and giving you the freedom to walk rather than catch another form of transportation.

Built to an impressive single piece composite monocoque structure and with large wheels like a bicycle, Gita can navigate all terrains. And with its 360 degree camera, it can also avoid all of the obstacles, pedestrians and anything else in its path.

Its onboard batteries will last for a full eight hours when operated at walking speeds, meaning that you’ll probably get tired before it does.

The PFF team is also working to make the vehicle autonomous, allowing it to be summoned when needed, rather than following you all day. As design and engineering challenges go, this is a pretty hardcore one; composite manufacture, the integration of complex sensor and software systems as well as load bearing requirements, all of which feed into a product that needs to look as good as it performs.

PFF’s first product is Gita, an intelligent and nimble cargo vehicle

High expectations

So is Gita what you would expect from Piaggio, a company renowned for moving people around cities in more traditional two wheeled motor vehicles and compact commercial vehicles? Would you associate the group behind the iconic Vespa with developing an autonomous cargo carrying robot?

To answer these questions and more, we sat down with Rosie Kotelova (PFF’s senior designer) and Amos Ambler (PFF’s mechanical engineer) to discuss how PFF came to be and some of the challenges it is facing.

D3D: I’m curious as to why Piaggio Fast Forward was started and whether the result (Gita) is what you always had in mind?

Rossitza Kotelova: Our CEO, Jeffrey Schnapp [founder/ faculty director of metaLAB (at) Harvard and faculty co-director of the Berkman Klein Center for Internet and Society], had a relationship with the Piaggio Group, mostly from a book that he was writing on the history of the company. At the same time, Piaggio realised it would need to innovate differently to be able to compete in the emerging transportation markets. It also realised that it has a long history of processes already in place that are hard to break into. So saw this as an opportunity to get Jeffrey involved and start thinking about ‘What is the future for lightweight transportation?’ and where should Piaggio start looking to next for the future?

I think that’s part of its history, always reinventing itself; Piaggio started out as an airplane company, then moved to the Vespa scooter. Now they’re producing two, three and four wheeled vehicles.

When PFF was started, it hired four designers initially. The company was presented to us as an idea company tasked with looking and thinking about innovative ideas, research, development and building a picture of transportation at a high-level for concept development. We went through that process for a good six months and from this exploratory process came the concept of Gita.

The Piaggio board and its advisors saw the potential in Gita and decided that it was something they wanted to pursue, so turned PFF into a product development company to actually make this thing. It was an evolution – it came out of this process of iterating through concepts and design.

Cargo is the key to Gita’s function — it has 2,000cc of capacity and a loading max of 20kg

D3D: It’s interesting to note the comparison between the monocoque-like, multi functional form of the Vespa scooter to that of the Gita and how you’re creating a structural form which is also the exterior facing surfaces. Was that accidental or were you influenced by the parent company?

Rossitza Kotelova: Our chief creative officer, Greg Lynn, has been working with this idea of part reduction and how you can do multiple things with a single part in his own architectural practice.

To him, as part of his research throughout his career, the Vespa has had a heavy influence. It’s a combination of having that history and realising that is the way that the Vespa was created and then his own interest in pushing this idea further.

Amos Ambler: It’s funny because this was something I was excited about before I ever came to PFF. Adding simplicity and lightness to engineering is a mentality that has always interested me – and you can definitely see it across our company. It’s in the DNA. The goal is to make the most refined product we possibly can.

Right from our earliest prototypes, these have been a much more refined, complex, shape than you would usually find in a product company.

We’re driven with the mindset of keeping the product as simple as possible.

D3D: As you move towards your launch date of 2018, is it your team that’s going to handle production or do you hand it off to a manufacturing partner?

Rossitza Kotelova: We are growing the team to do this, but we’re also bringing in expertise from Piaggio and in the process of expanding out our manufacturing team.

Amos Ambler: Piaggio is an incredible resource we can access and leverage, so we can build off of this.

Gita has large wheels like a bicycle, so it can operate on irregular surfaces, indoors and outdoors, on sidewalks and streets

D3D: I’ve been thinking a lot about autonomy of late and how design is crucial to acceptance. Looking at the front of Gita, how do you decide how that looks? Obviously there’s a functional requirement, but do you make it cheerful, do you make it serious? For instance, if you painted it matt black, it would look terrifying.

Rossitza Kotelova: It is mostly functional, but it has an aesthetic to it and we’re trying to keep everything as a seamless part of the surfaces, but I guess most of these features are driven by where these components need to be placed to work properly. Then we look at how to blend them into the surface most easily so it can be manufactured using a composite moulding process.

Amos Ambler: It has been driven home, from a mechanical engineering stand point, to not let what it’s going to look like affect our decisions. We tell the design team what we need and we work together to make it happen. Function always comes first. What’s the saying? Form and function are one.

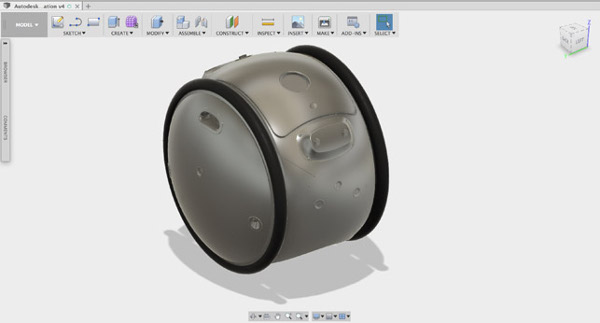

Fusion 360 at Piaggio fast Forward: Integrated design, engineering and collaboration

We first met Rossitza Kotelova and Amos Ambler at an event in Boston earlier this year, where they discussed Piaggio Fast Forward’s design process, its highly collaborative working environment and how the company’s workflow means that it has been looking for a replacement for its SolidWorks and Rhino set-up.

According to Ambler, the reason for the replacement is that this set-up didn’t work that efficiently and, as such, the team are in the process of moving to Autodesk’s Fusion 360.

With Fusion 360, the whole team, both in design and engineering, is able to use the same cloud-based platform, using a common set of data, without any heavy conversion or loss of intelligence or design history.

Alongside this, collaboration is key amongst the PFF team, both between different groups in its Boston headquarters, but also to enable their extended partners in both LA and Italy to review the same data.

Here Ambler outlines the reasons for the move to Fusion 360:

“We have a very open office in Boston and that facilitates interaction between design and engineering and software.

The PFF team is also interesting because our chief creative officer is based in Los Angeles and we have a lot of interaction with Piaggio’s engineers in Italy — this results in a lot of extra normal methods of communication.

Our office is a hive of activity. Much of our time is spent designing parts in the morning, then making them in the afternoon in our fully equipped workshop. All of which helps with the fast pace of design.

We also face a lot of challenges. Our development method is uncommon to say the least. Our management is very visually led, so they want to see a product in person and see it operate as soon as possible — this means we need to incorporate very complex surface design into the very earliest prototypes. We also need to host remote sessions with the Italians and California.

Because we build full prototypes so early in the design process, it requires a constant evolution and remodelling of many of the surface features. When we have been working with multiple CAD applications, this process becomes very time consuming. With each file conversion, we lose design history and reference geometry, all of which makes automatically updating the CAD files almost impossible.”

An interview with the team at Piaggio Fast Forward

Default

Pingback: Piaggio and Trimble collaborate on robot-swarms – BIMNEWS

Pingback: Piaggio and Trimble collaborate on robot-swarms |

Pingback: Piaggio and Trimble collaborate on robot-swarms | Bina

Pingback: Piaggio and Trimble collaborate on robot-swarms - Software Mile.com

Pingback: Piaggio and Trimble collaborate on robot-swarms – BIM Resource Center