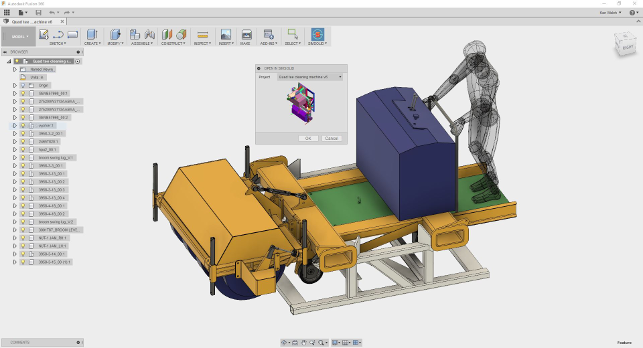

SIMSOLID integration add-in within the Autodesk Fusion 360 user interface

SIMSOLID is a new company founded by CAE veterans Ken Welch and Victor Apanovitch who started out by asking a simple question: “why does the geometry used in the Design and Structural Simulation worlds have to be so different?”

Their feeling is that, although over the years CAD system geometry has evolved (wireframe to surfaces to solids and parametric to direct), simulation has remained stuck using the same beam, shell or simplified solids paradigms invented over 50 years ago. And although some FEA vendors have focussed on creating “CAD to Mesh” steps they are often labour-intensive, error prone and require experts in both simulation and CAD, and even then are rarely well integrated within the product design process. So, they set up SIMSOLID to change all that.

D3D: Let’s start with the basics. SIMSOLID has developed a meshless FEA method. How does it work?

KW: SIMSOLID is a generalisation of classical FEA. While it uses the same variational principals, the difference comes in how we build approximation functions and associate them with geometry. SIMSOLID doesn’t break the system into finite elements, instead it discretises the original geometry in a more abstract mathematical way.

SIMSOLID uses high order functions built on the fly during the solution phase. Geometry is decoupled from these functions, which allows the freedom to use the most accurate functions possible. For example, when performing thermal analysis SIMSOLID uses harmonic polynomials which precisely meet the thermal equation. Multiple solution passes are performed and with each pass errors are quantified and the functions are adapted. In contrast to other commercial FEA products, adaptive analysis is not an option. It is always active, even for large assemblies. In this respect, SIMSOLID is unique in the industry.

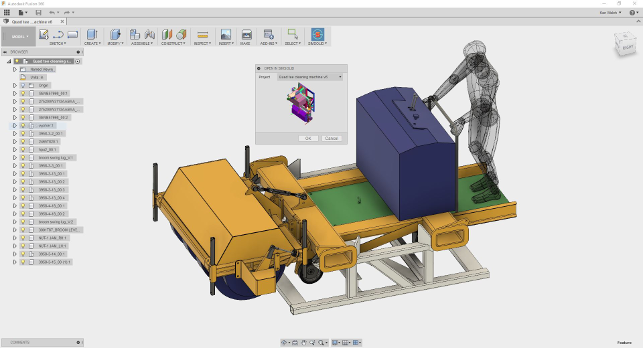

Static analysis in SIMSOLID of the above cement form sweeper and support frame — 223 part assembly

D3D: What are the advantages of a meshless approach?

KW: SIMSOLID is intended to be used in up front design. Its primary advantage is its ability to provide quality structural performance insight fast. It works on unmodified, fully featured CAD geometry and does not require a mesh. It can analyse large assemblies and complex parts, yet total solution time is typically measured in seconds to minutes. This rapid feedback makes it an invaluable tool for the design process where the requirements are constantly evolving.

To process design change seamlessly, SIMSOLID is directly integrated with SolidWorks, Autodesk Fusion 360 and Onshape. With SIMSOLID’s unique multi-CAD design studies, all analysis definitions update automatically when design changes are made so analysis set-up rework is minimised. It even works with generic STL and is capable of solving geometry with extreme complexity. This is especially useful for today’s complex 3D printed parts containing complex lattice type structures.

D3D: How do you handle interaction with other simulation systems which might require a mesh?

KW: Well, we have not had the opportunity to work with other FEA or CFD systems yet. That said, SIMSOLID has no issues to interact with mesh based systems. For example, SIMSOLID could use boundary conditions that came from CFD node based pressures values or it could export displacements and stresses into external topology or shape optimisation systems. Since we map our data from and to the underlying CAD geometry, it is possible to work with any system capable of doing the same.

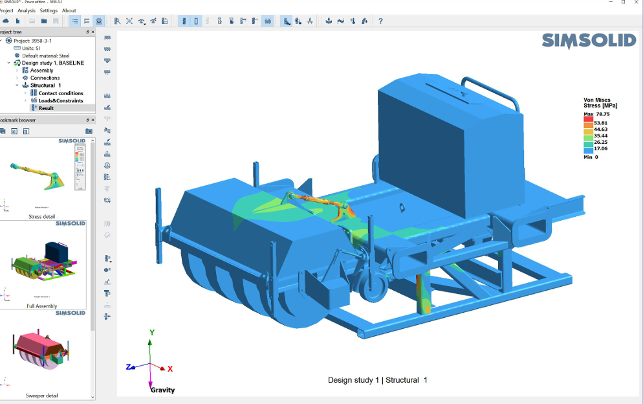

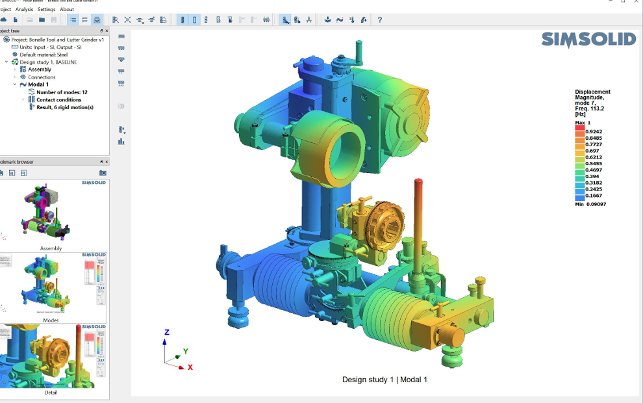

SIMSOLID modal analysis with modal participation factors of a large space truss — 549 part assembly

D3D: Do you have any quantifiable information with regards to the accuracy of your methods compared to more traditional approaches?

KW: Certainly. On our website, we provide a complete Validation Manual which includes an extensive list of NAFEMS benchmarks and other reference solutions.

There are also several validation articles in our blog written by customers and partners. Of course, most customers want to do their own internal testing. SIMSOLID has been extensively benchmarked against other FEA products as well as physical test data.

One comment on “accuracy”. When doing structural simulation, it is important to consider if you are solving the problem right AND if you are solving the right problem.

Accurate solutions mean little if the problem is improperly defined and this is often the case with traditional FEA. The limitations in modelling and solution time mean that tradeoffs must be made and each trade-off is a possible source of error. Most design engineers are not prepared to answer questions such as; which part to analyse, what loads to use, what features can be removed, what mesh distribution to use, etc. SIMSOLID removes these barriers.

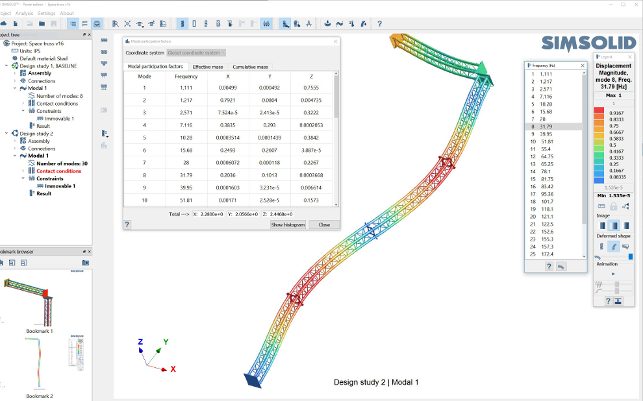

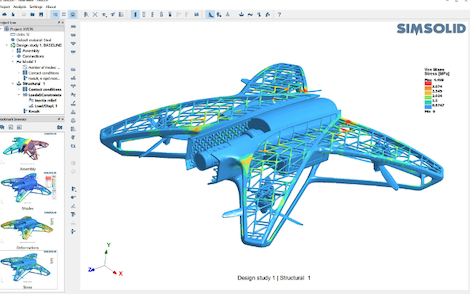

SIMSOLID static and modal analysis of the X VEIN concept 3D printed drone — 126 part assembly

D3D: If someone has a background in traditional FEA, what are the ways in which they need to adapt their thinking when trying SIMSOLID for the first time?

KW: Interestingly, we found that first time SIMSOLID users, well trained in FEA, tend to perform the same steps they usually do in FEA; de-feature parts, merge assemblies, remove small parts, etc. None of which we recommend.

Users without extensive FEA expertise usually do it right by taking the model as is and following SIMSOLID’s simple workfl ow of quickly analysing load paths on the full assembly first and then drilling in, using part based solution adaption, to examine local stress details.

D3D: Acceptance in the simulation community is key — how do you go about changing perceptions in an industry that many would consider resistant to change?

KW: I agree. Change in the structural simulation market is a slow process. But I do want to emphasise that SIMSOLID does not replace traditional FEA verification tools. It simply provides a way to ask new questions about the performance of large assemblies and allows design engineers to rapidly gain design insight. This moves simulation forward in the design cycle to a point where it can have the greatest impact.

The desire to do simulation here is real. And the perception today is that classical FEA is not a good fit. The industry is looking for a better solution and SIMSOLID is trying to fill that need.

Modal analysis of large assembly

D3D: Can you describe the sweet spot for SIMSOLID? What would be the ideal use case to grab people’s attention?

KW: Large assemblies and complex part geometry. People are surprised by the size and complexity of the models that can be easily analysed. Our customers typically have assemblies with 200 to 1,000 parts, sometimes more. With the market rapidly moving toward 3D printed lattices and other perforated structures, there are opportunities to analyse these complex shapes even within the context of the full assembly.

For more in-depth details about the product, download the technology white paper on SIMSOLID’s website.

We speak to Ken Welch, CEO at SIMSOLID about its new structural analysis tool

Default