Necessity is the mother of invention. This proverb is certainly true in the case of Gilo Cardozo, British aviation engineer and seasoned adventurer.

In 2007 having created a paramotor (a foot-launched powered paraglider) that could get him to the summit of Everest, he needed an engine to power it. Not being able to find anything up to the job, he set about designing his own four-stroke rotary engine.

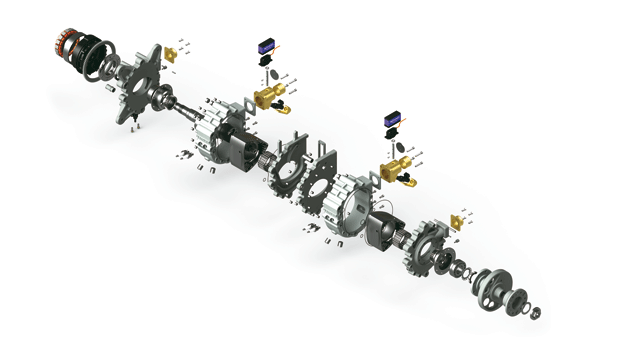

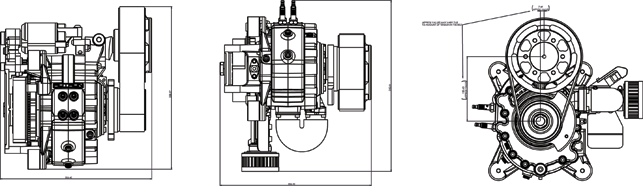

Exploded 3D CAD model of the Rotron RT600 Twin-Rotor Engine

Having achieved his Mission Everest goal, Cardozo decided to set up a rotary engine manufacturing brand within his paramotor business Parajet called Rotron Power in 2008, both of which are under the parent company Gilo Industries Group.

This subsidiary has grown over the years and ironically no longer supplies Parajet with its engines. Rather, Rotron manufactures advanced rotary engines for Unmanned Aeronautical Vehicle (UAV) applications.

“Rotron is our largest business within the group supplying high power to weight ratio engines for extreme applications, predominantly within the commercial aerospace sector,” says Jim Edmondson, CEO of Gilo Industries Group.

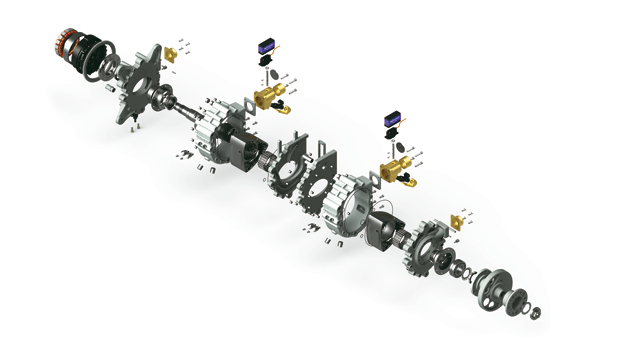

Rotron’s purpose-built engine production facility encompasses full design, manufacturing and test capabilities

Ambitious goal

Rotron’s aim was to develop a rotary engine that could deliver a higher power to weight ratio compared to any other UAV specific engine while remaining small, lightweight, reliable and with almost zero vibration.

“We came up with some unique patented ideas. For instance, the tip ceiling, which used to be a major problem with rotary engines, has been solved because of new technologies and materials.

“But the major issue is the heat build up in the centre of the engine, which is hard to extract. So we developed several different unique ideas that extract energy from the centre of the engine allowing the engine to have longevity and more reliability,” comments Edmondson.

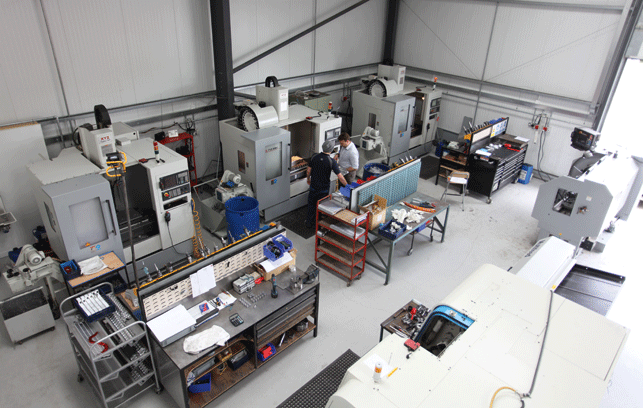

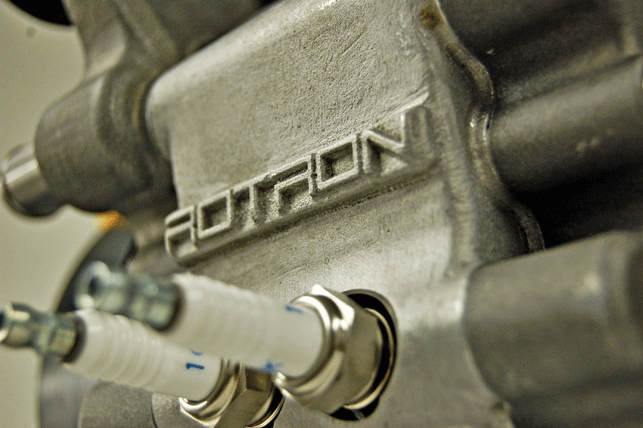

The Rotron’s charged cooling combined with other proprietary cooling systems delivers a reduced heat signature and reduced component wear

For instance, the Rotron Pressurised Cooling (RPC) system offers cooling and lubrication to the engine and means it delivers a higher endurance lifecycle and is less prone to metal fatigue and component wear compared with existing rotary engines.

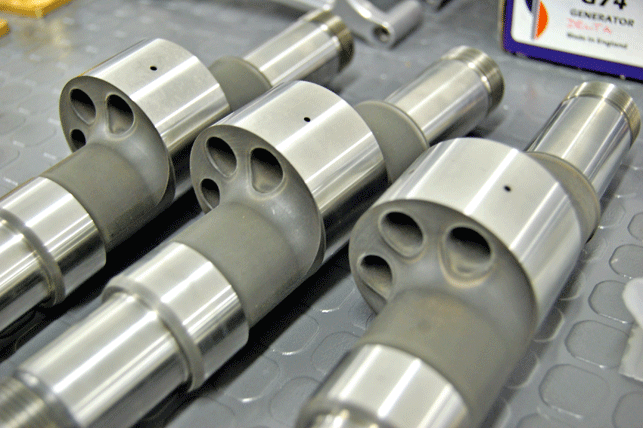

Precision engineered single-rotor eccentric shaft machined from a single billet

“We have developed this water cooled shaft which means that water can be funneled through the centre of the shaft thereby cooling the shaft as it works, which then also has a cooling effect on the internals of the rotor — but also the water goes round the external or gap in the housing so it cools from the outside and the inside and it’s had a massive effect,” says Charlie Nicol, Rotron’s head of operations.

Close up of Rotron’s lightweight cast rotor housing of an LCR engine

Work and play

The design and development work of these engines was carried out by Rotron engineers using predominantly SolidWorks, of which it has ten seats in-house, making use of the tool’s bolt ons including failure mode and effects analysis (FMEA) and computational fluid dynamics (CFD).

But Edmondson stresses that, as important as it is to have good tools, the company wants to instil a culture of innovation by ensuring that its employees enjoy being at work. “If you’re making inspiring technology, it should be an inspiring place to work as well,” he says.

So, activities that the company organises for all employees includes Boot Camp, a bicycle ‘chain gang’ (a group cycle ride after work), getting inspiring speakers to give a talk (the most recent being James Holland, a World War Two aviation historian) and a ‘Fly to Work’ programme where they can get to fly a paramotor.

“If your employees are excited about coming to work on a Monday morning, then you get the best out of them. It becomes an exciting environment and that is what it should be about, not this crazy mathematical problem that you have to solve using SolidWorks,” comments Edmondson.

What is a rotary engine?

A rotary engine is essentially an internal combustion engine that can achieve four strokes — intake, compression, combustion and exhaust — while rotating. German engineer Felix Wankel first had the idea for this new type of gasoline engine, which converts rotary motion directly into driving force, in 1919.

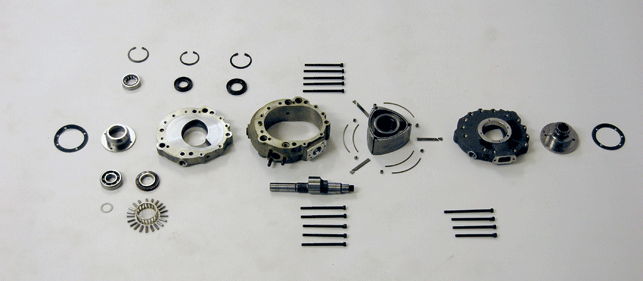

As opposed to the common piston engine, with its pistons all changing direction, in a rotary engine all parts rotate, moving in one direction. Advantages of this type of engine include simplicity, smoothness, compactness, high revolutions per minute and a high power to weight ratio.

Over the years, various companies have improved on Wankel’s engine design, however, it has a number of inherent problems and has often been deemed impractical.

“They are plagued with problems because if you look at the tips of the rotor, when they spin round they wear quite quickly,” explains Jim Edmondson, CEO of Gilo Industries Group. “For that reason, people think that rotary engines have a very low lifespan.

“But in the aviation world, as well as other applications such as motorcycles and outboards, what is important is a very high power to weight ratio where the lifespan of an engine isn’t as important as the weight impact,” he adds.

Heavy fuel engines

All of this hard work and play has led to Rotron’s most recent innovation, which it launched at the Farnborough Air Show 2014 last July — commercial off the shelf (COTS) heavy fuel engines in the 20-60 HP engine category.

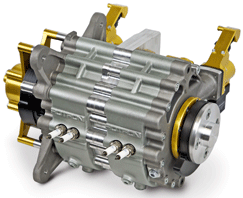

As a heavy fuel version of its gasoline RT300 (single rotor engine) and RT600 (twin rotor engine) engines, Rotron claims to be the only manufacturer in the world producing a heavy fuel propulsion system within this engine category.

Until now, UAV manufacturers have not been able to offer heavy fuel engines within the Medium Altitude Endurance (MALE) UAV market sector. This is largely due to the extreme power-to-weight ratios required in such propulsion systems; the size of the engine makes it difficult to propagate the flame and ignite heavy fuel.

However, the UAV market, especially for use in defence and military applications, has coveted heavy fuel engines since NATO’s announcement of the single fuel policy in 1997. This policy states that one single fuel should be used across all motorised military assets from chainsaws to UAVs by 2020.

The way in which a diesel engine, or a compression-ignition engine, works is that it uses the heat of compression to initiate ignition and burn the fuel that has been injected into the combustion chamber. But a fair amount of mass and energy is needed to make that happen and that is why diesel engines are quite big and so not suitable for small applications such as UAVs.

With fewer moving parts, the Rotron engine offers easier maintenance

“You could use spark ignition, the same as with a petrol engine, but that has inherent problems because diesel is so inert that you can take it on a plane in a flask and not be stopped as you can’t light it with a match or flame. It has to be heated up to 98 degrees Celsius to even start lighting it,” says Edmondson.

Leading the way

With the challenge set, this small manufacturer began work on its heavy fuel engine around three years ago. Its goal was to lead the race in developing a solution that the military could use in its UAV applications such as search and rescue, anti-piracy and pipeline inspection.

The main innovation within the resulting engine is flame propagation — making the flame burn smoothly across the whole flank. Essentially, what Rotron has managed to do is align the spark plugs so that the engine doesn’t have one or two spark plugs, as in its petrol variant, but four.

“With four spark plugs, as the ignition starts at the beginning of the rotor, it starts pushing it round, then the second two fire almost instantaneously after with lighting the back of the fuel. But what we have also done is work out — I can’t go into too much detail — how to heat the fuel up to 98 degrees Celsius before it is actually injected into the engine,” explains Edmondson.

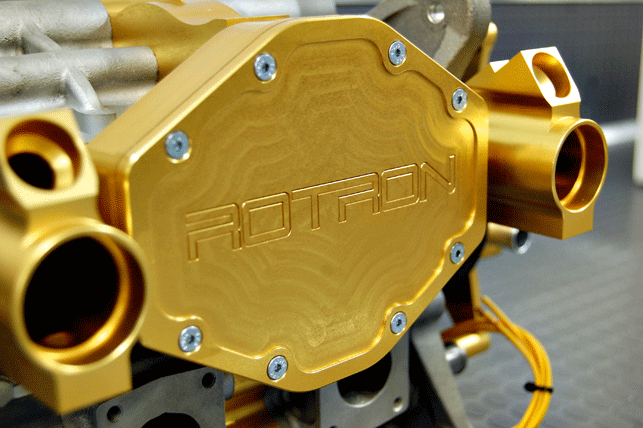

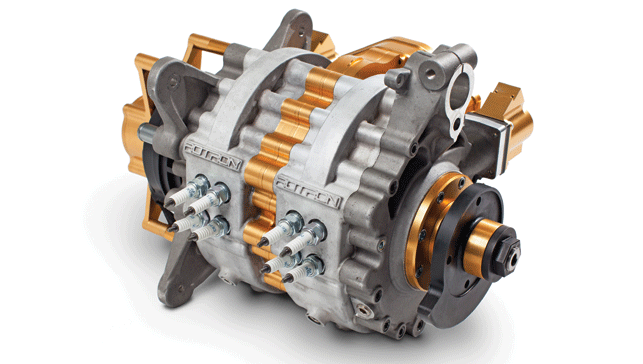

The Rotron RT600HFE: suitable for UAVs requiring 56HP

Rotron engineers relied heavily on computer modelling to work this out. They weren’t only modelling flame direction, but also using CFD to calculate property strengths and to analyse where failures could occur.

This analysis work was carried out in conjunction with physical trials. So, a part is first designed and analysed in the 3D world before it is built and physically tested. That information is then correlated back to simulation.

Doing it this way means that not nearly as many prototype rotors were destroyed, as they would have been if no simulations had been carried out. And with it costing £1,000 for each prototype built, a great deal of money was saved in the process too.

Testing, testing

In November 2014, Rotron engineers prepared the RT600 heavy fuel engine for its first application-based test programme. Having completed a complex installation into the test mule at its facility, the team performed pre-testing on all engine components and ancillaries to ensure optimal configuration setup.

Having received very positive first results, future developmental testing will centre on the new starter system that is currently being prototyped.

These test results will be supported by data collected over an extensive pre-flight development program. For this, Rotron has secured four launch partners who will be working with the manufacturer to test the engine.

One of these is a helicopter manufacturer, which will use the engines in unmanned helicopters to carry out power line inspections.

“As you can imagine, power lines going across mountain ranges are very hard to track but these helicopters can shoot along them and with special cameras can pick up heat impacts from the transistors.

“With our engines being high power to weight and with very little vibration they are ideal for such UAVs,” describes Edmondson.

Although full production of the heavy fuel engines is only scheduled for 2016, Rotron moved into its own facilities in May 2014, which is right next door to the factory it used to share with Parajet.

Already some new investments have been made to the shop floor including a DEA Coordinate Measuring Machine (CMM) to deliver precise, accurate manufactured components for the new rotary engines.

Target Drone Engine: suitable for Short-life UAVS & Aerial targets

To further improve its processes, the design studio is also in the process of implementing SolidWorks Enterprise Product Data Management (EPDM), a data management system that Rotron hopes will get its design data under control and improve the way it manages and collaborates on product development.

“I think any company that has grown from five people five years ago to +50 today, needs to have these processes put in place. This tool from SolidWorks should be a huge help to us in terms of control and configuration,” says Edmondson.

When full production of the heavy fuel engines begins in 2016, 20 per cent of the engine will be made in-house with the rest outsourced. But all suppliers will be sourced in the UK as Rotron, and its parent company Gilo Industries, passionately believe that design and manufacturing is critical to the future economic growth of British industry.

rotronuav.com

Rotron’s History

In early 2007 Rotron founder and chief technology officer, Gilo Cardozo, pursued a childhood dream: to fly a paramotor 30,000ft over the summit of Everest.

Having teamed up with friend and TV personality Bear Grylls, Cardozo had just seven months to build two paramotors.

However, the most powerful paramotor engine available was barely producing 30hp and was far too heavy to launch at the desired altitude. So, he also set about building a four-stroke rotary engine that was more compact and 50 per cent lighter than a piston engine equivalent.

The basis of the Everest engine was a 294cc single rotor engine producing 40hp as a standard normally aspirated engine.

The engine included a miniature centrifugal supercharger fitted with a miniature intercooler to ensure the air was as cold and dense as possible when entering the combustion chamber. The supercharger was modified to be spun at up to 200,000rpm in order to simulate sea level atmospheric pressure of 1 bar at 30,000ft.

To eliminate the problem of icing, the supercharger was placed before the fuel delivery system. The heated and supercharged air was then sent through an intercooler before passing the injector at an average of 25 degrees Celsius.

After four months of design, development, testing and manufacturing, the engine was finally ready. With just two days before departure, the second engine was completed.

On 14 May 2007 the two pilots took off and in a flight that lasted four hours they achieved a paramotoring world record of 29,494 feet.

On completion of the expedition and building on its success, Cardozo continued to develop his rotary engine and looked for a commercial platform for the technology. Rotron Power was born.

UK designer’s new UAV engine drives it to new heights of engineering excellence

Default