Glass packaging has become an art form as well as a marketing device.

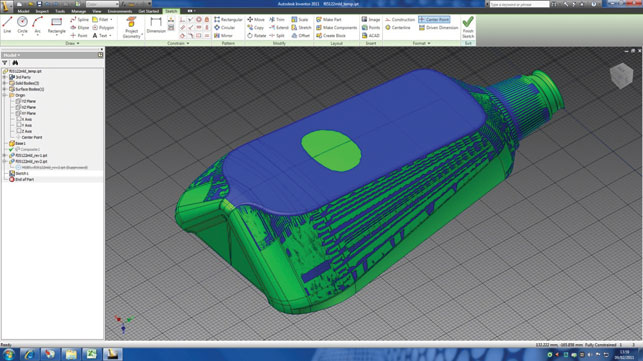

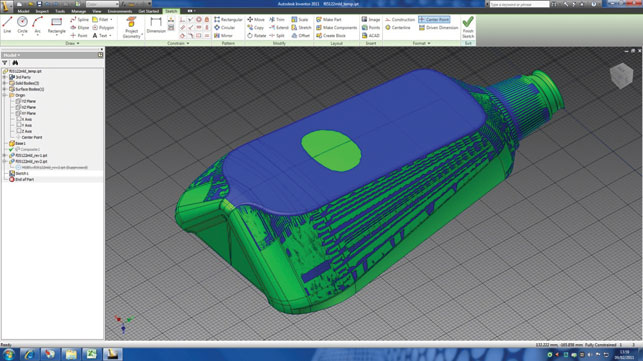

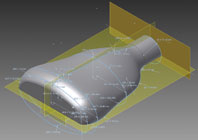

Detailed and accurate 3D models are created with Autodesk Inventor

This puts pressure on specialist glass designers; the more innovative their work, the more engineering challenges they have to address.

But there are design and engineering tools at hand to help them collaborate more easily with client creative and branding experts on the one hand and production teams on the other.

Take the containers designed by the Leeds-based company Allied Glass for the premium spirits sector.

The aim with Langtons Gin, for instance, was for the bottle to speak for itself without any additional packaging.

The result is a unique pack achieved using a combination of 3D modelling techniques to replicate the intricacies of The Lakeland slate, where the gin originates in the Skiddaw region of England, onto the bottle’s surface.

“Premium drinks manufacturers want a bottle that reflects their values but also has shelf appeal. Shapes are becoming more complex and there’s a growing demand for unusual features,” explains Chris Todd, Allied Glass product innovation manager.

More than skin deep

Increasingly the Allied Glass design team works closely with clients’ design consultancies and branding experts.

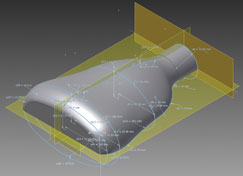

But, they must also ensure that accurate dimensions are available to make the mould, that the bottle will hold the correct amount, its cap will close correctly and that the design will allow the bottles to run smoothly down the filling line.

“One of the difficulties was getting ideas from our heads onto the screen,” says Steve Glover, project design engineer. “Another problem was volume calculations.

There are ways of working out the cubic centimetres of a traditional bottle shape, but when it comes to more random shapes this becomes much more time-consuming and error prone. A great design is no good if it doesn’t hold the right amount of product.”

All in one

Allied Glass worked with digital design specialist Symetri to implement new digital prototyping tools. Now, the designers can draw shapes and forms on their computers, as if they were sketching on paper.

This gives them free rein to capture their thoughts and experiment with ideas.

These concepts are then transferred to Autodesk Inventor software for more detailed and accurate 3D modelling.

“Because the software automatically works out volumes, we no longer have to calculate them ourselves – and then recalculate when we make changes,” comments Glover.

“We still might make revisions but, because the design model and the documentation behind it are automatically updated, we can quickly measure the impact. It’s all a question of fit – down to whether the labels will fit correctly on the bottle.”

Allied Glass has benefitted a great deal from the visualisation software as it enables the design team to create photo-quality visuals and animations. Glover says,

“Our aim was to produce the same standard of presentation materials as a design agency. We can now do this as an integral part of our workflow.

“It’s vital that we work with all stakeholders to make key decisions at early stages of the design. We show our ideas in a way that’s straightforward for everyone to understand, but also reflects the quality of our work. It makes for better client relationships and fewer changes further downstream.”

The designers and engineers are now also experimenting with digital sculpting and painting tools. Used extensively by digital artists for games development and visual effects, these tools are also becoming increasingly valued in some areas of manufacturing.

“We now speak the same language as our clients’ marketing and design teams. On the other hand, we can also talk engineering and mould-making to the production team,” comments Glover.

“Because much of our routine work is now automated we can take time to be more creative. We are much more in control of our designs and can be far more proactive. It’s helping us to realise our vision of providing a complete solution from concept to final product for our customers.”

symetri.com

allied-glass.com

Digital design innovation gives glass manufacturer the clear advantage

Default