The start-ups at CRL are diverse, creating products from toys and musical instruments to healthcare devices and underwater drones

In its heyday, it was responsible for bringing the sounds of The Beatles, Elvis and The Rolling Stones to households around the world. Today, the former home of music company EMI on London’s outskirts is once again a hive of activity.

Its heritage is more complex than the name ‘The Vinyl Factory’ suggests. While the hit sounds of the day were being pressed and packed, a small corner of the sprawling 17-acre, 22,000-worker site in Hayes, Middlesex, was home to the Central Research Laboratory (CRL).

Here, some of the country’s best engineers pioneered new electrical and broadcast technologies, developing airborne radar, stereo sound transmission and even the first CAT scanner.

That original hub of excellence is long gone, but recently, the area has undergone wholesale rejuvenation. Backed by new high-speed rail links and support from London Mayor Boris Johnson, new offices blocks with shimmering glass facades have been constructed.

As its developers looked for ways to reintroduce industry to the area, it became clear that the resurrection of the Central Research Laboratory (CRL) and its work in technology development should lie at the heart of their plans.

“We wanted to bring [innovation] back, and one way that really interested us was to set up an incubator focused on hardware,” says Ashley Sayed, operations director for the new CRL, operated by the Vinyl Factory site’s regeneration agent, U+I Group.

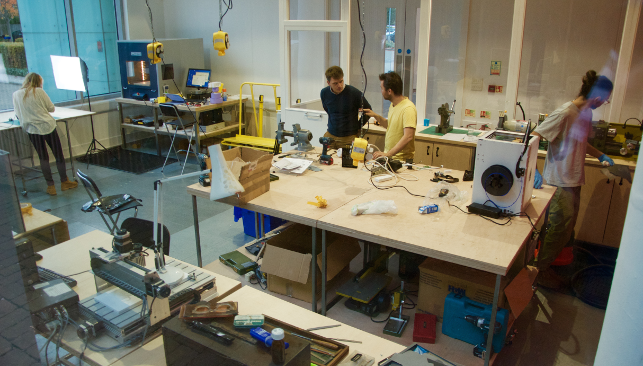

Producing physical prototypes is key to the hardware startup process

Early stages

The incubator model has taken off dramatically in the last ten years, with start-ups signing up and offering shares in their companies for the chance to receive expert guidance, workspace and facilities, with the goal of getting their businesses through the difficult early stages.

Most recently, the US has seen the growth of hardware incubators, focused on making physical products, rather than software and apps. It’s a much tougher business, given that physical products require more capital to be risked in the search for success.

The CRL incubator is the first of its kind in the UK, having began its pilot programme in September 2015, taking 11 full-time hardware start-ups into its 3,000 square feet of space, central to the new Vinyl Factory site.

“You can’t put a hardware company through a software type accelerator,” Sayed explains. “We saw that this was happening, and that there were companies falling out of them and not really being supported. We set out to build a campus that could provide workspace, prototype facilities, funding and be an incubator tailored to hardware start-ups.”

Over 100 applicants pitched for the chance to join the 12-month scheme, based on the criteria that they needed to be developing a physical product; wanted to be a scalable business; and were committed to the programme and to being located on site at the Vinyl Factory.

“They’ve got to want to be a business, and that might seem a bit stupid, but it’s really important,” says Sayed, emphasising that, while some applicants for the programme had really good ideas, they didn’t have that hunger to scale up.

The need for business focus shows the balance that the CRL incubator has to strike: great products, honed for a market, designed for manufacture and ticking all the right boxes for investors at all stages.

The start-ups on site are a diverse bunch, with no two alike, creating products from toys and musical instruments to healthcare devices and underwater drones.

Most have a connection with nearby Brunel University, a partner to the incubator programme and the institute from which most team members graduated.

The startup programme involves a strict regime aimed at getting start-ups ‘investor ready’, helping them to build the right set ups, finetune their business models and get the right products to market.

Support network

One of the key tasks is to provide what CRL calls ‘Fundamentals Support’ – the building blocks of creating a product that works and a business that can attract the necessary funding for its forward development.

For the first three months of the programme, all of the start-ups take part in workshops and seminars, with CRL bringing in specialists from the business world to provide expert guidance.

Financial advisors from KPMG will hold workshops on best practices for working with investors, for example, while lawyers from IBB Law, a specialist in trademarks and patents, will run through what they need to do to keep their intellectual property safe.

Additionally, all teams have their own individual mentor, selected via a matchmaking process early on, to act as an impartial guide. Usually, these figures have in-depth experience in bringing products to market for big-name brands, and their time and advice is paid for by the CRL.

Day to day, the 11 start-ups are supported by an in-house CRL team, who come from a wide variety of different backgrounds. Some are experts in working with angel investors, others in designing for manufacture.

The staff spend a lot of time early on in the programme identifying knowledge gaps both in individual start-up teams and the group as a whole, so that weaknesses can be addressed quickly.

Solving problems can be as easy as lining up a participant for a oneon-one chat with an expert, but if all 11 teams are struggling with a particular topic or issue, then the CRL team may set up a workshop in which everyone will take part.

“When start-ups come in, they’re naturally focused on the product.

It’s up to us to explain how funding works and to get them to understand how dilution works,” says Sayed of the various, and often complex, funding stages involved in growing a start-up.

By the time start-ups reach the incubator, all the teams have between three and six co-founders. Until then they’ve either been self-funded or received grant money, and all are initially aiming to get their seed round and that all-important first valuation of their business.

Once they receive the seed investment, they then progress to pretrials and pre-production, where developing a route to market and honing their products for mass production becomes key.

With his background in developing products for the likes of Philips and Motorola and his extensive connections with contract manufacturers in the Far East, this is where Sayed comes into his own.

“This is probably what makes CRL different to any other incubator in Europe at the minute, as we focus on design for manufacture right from the outset,” he says.

A custom-fitted workshop on the site is designed to accommodate all the needs of the very different start-up teams, and has everything you could need for developing prototypes through to small batch production.

CRL brings in specialists from the business world to provide its start-ups with expert guidance

Proof of concept

The shared space is populated with workbenches and hand tools, while 3D printers, laser cutters and a pair of Roland MDX 540 4-axis CNC machines provide a digital edge.

On top of this, there’s a dedicated electronics bench and outside, a 40-foot shipping container that’s home to noisier equipment like lathes and cutters.

With each of the 11 companies’ products targeting very different audiences, once past the seed fund stage, they will typically begin to move forward at different paces, governed by very different routes to market.

This impacts their cash requirements, resulting in different business models and different types of investors from start-up to start-up.

Quite quickly, the differences in each business’s requirements become even more pronounced, as they work towards new levels of funding, or take on more complex prototyping. The CRL programme adjusts to accommodate these needs, with individual start-up teams within the group soon branching off on their own pathways.

Regardless of the success achieved, once the 12-month programme ends, CRL offers participants follow-on space as part of its recent expansion into a new 10,000 square foot facility on the Vinyl Factory site.

As the companies grow and add new staff, new group desk spaces, meeting rooms and workshop areas will be needed, while a new crop of 11 candidates will begin the CRL programme.

By setting up CRL, the Vinyl Factory’s site developers will be hoping that its investment in strong new business foundations will mean partnered growth and success for their new site, which has plans to develop further, to include more office spaces and even housing.

For now, current programme participants are still in the early stages and the buzz of excitement is almost palpable. It’s an atmosphere rich in new ideas and technologies, one that recaptures what it must have been like in the days of EMI. The hope now is that the rebooted CRL will prove to be an equally pioneering enterprise.

We visit the CRL, the UK’s first hardware incubator programme for start-ups

Default