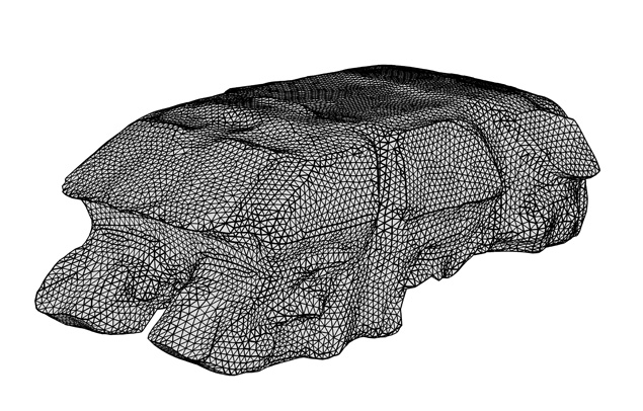

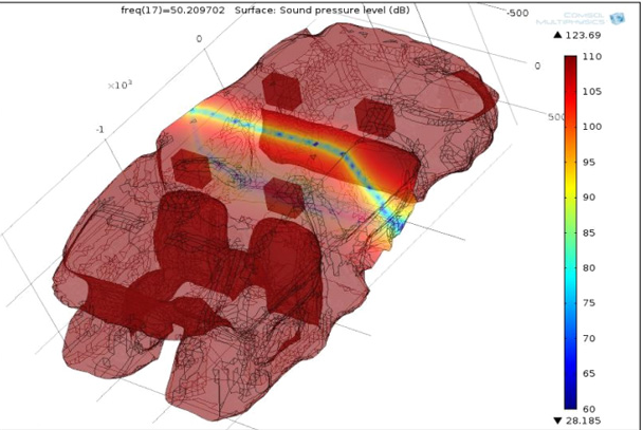

FIG.1 Surface mesh of the car cabin

Today’s vehicles offer extensive in-car ‘infotainment’ possibilities, from smartphone connectivity to state-of-the-art interactive displays and video screens. Harman is a market leader in these connected car set-ups and equips around four out of five of the world’s luxury car models with premium audio systems.

Each vehicle model requires its own configuration and Harman’s team of acoustic and simulation specialists ensure that different components and the acoustic characteristics of different car models are accounted for in their design processes.

Decisions must be made about the optimum placement and orientation of speakers. Factors relating to driver enclosure geometry – such as car doors – will also influence sound quality and must be considered.

The team uses physical experiments in conjunction with numerical analysis to accelerate product development by virtually ‘tuning’ their systems before creating a live prototype. This saves time on physical testing, and allows virtual tests to replace in situ listening, so that the team can design products even before final car designs are complete.

“We may become involved very early in the car development process, when a vehicle designer has not yet decided what is required from the audio system,” explains Michael Strauss, senior manager of virtual product development (VPD) and tools at Harman.

“Or we may only have basic details such as size and volume of the car cabin. Yet frequently, we need to present a concept within a few days, creating a tricky challenge to meet our clients’ requirements and deliver high-quality systems.”

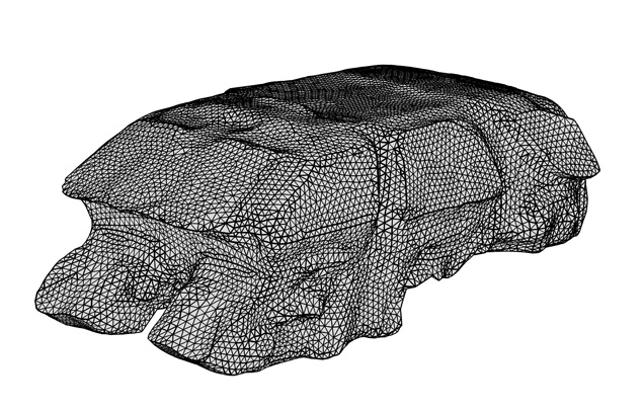

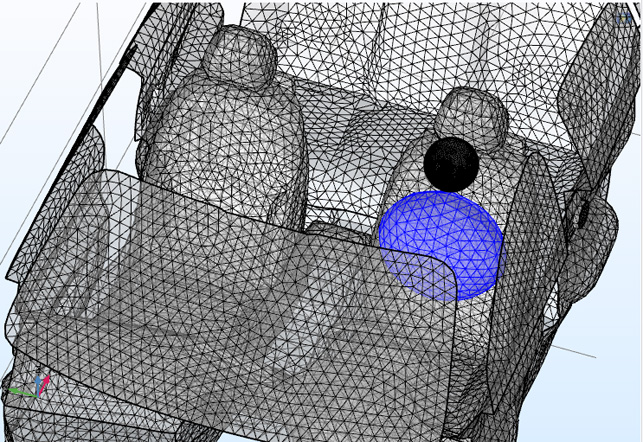

FIG. 2 Loudspeaker positioning in the vehicle interior

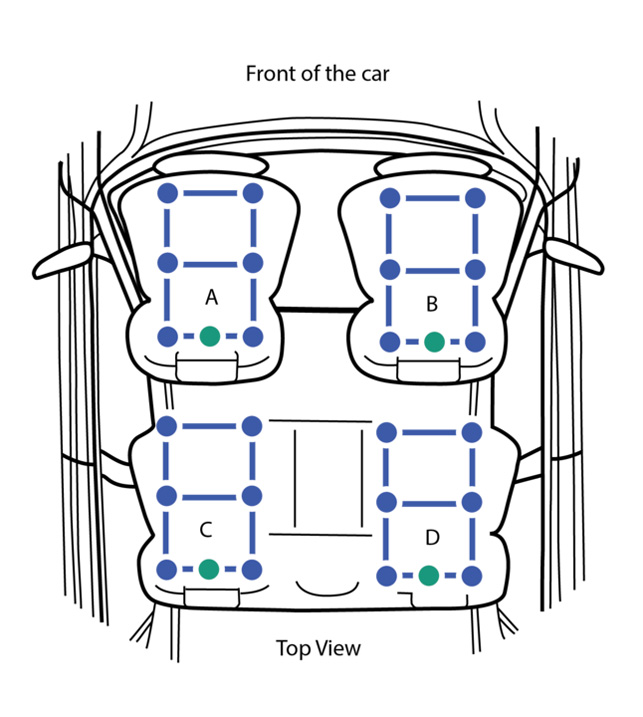

FIG. 3 Measuring sound pressure level at different locations

Comsol – A simulation opportunity

To provide clients with a response that is both quick and accurate, engineers at Harman turn to mathematical modeling in Comsol Multiphysics software.

“We needed capabilities for mechanical, acoustic and electrical simulations in one integrated environment and we wanted a program that would free up the time and effort spent on creating and updating our own tools,” explains François Malbos, principal acoustics engineer at Harman.

“The multiphysics approach is one of the most important parts of the virtual product development process,” adds Michal Bogdanski, simulation engineer and project leader. “We can explore how the acoustic behavior of a loudspeaker relates to any part of a vehicle structure – for example, the stiffness of a door – and then provide door design guidelines to our customer.”

In one case, they both measured and simulated the sound pressure levels generated by a loudspeaker in the cabin of a Mercedes-Benz ML car (Figure 2) in order to validate their numerical models and later use them to optimise acoustic equipment.

“Car cabin simulations are among the most challenging to run, because they cover many different areas of physics,” explains Strauss. Fortunately, Comsol software offers options to couple together acoustic, mechanical and electrical effects throughout the system.

To support company-wide engineering efforts, Strauss’ team established a library of validated models and known solutions, which supports performance predictions for a wide variety of loudspeaker configurations. “We are able to offer everything from a high-level trend analysis to a detailed design examining the performance of a subsystem,” he continues.

FIG. 4 Harman’s 3D scan of the car cabin

Comsol -Analysing performance

In one study, engineers at Harman used Comsol to create a simulation of a car cabin’s sound system in order to optimise the speaker acoustics specifically for low-frequency sound waves. They then designed a series of tests to validate the model. Once validated, the model allowed the Harman team to deduce the best loudspeaker set-up for a given car.

In validation tests, a loudspeaker was mounted on a rigid enclosure near the driver’s seat of the car. Four sets of microphone arrays throughout the cabin served to measure the average sound pressure levels at each location (see Figure 3).

For frequencies below 1 kHz, the loudspeaker was represented as a rigid flat piston tied to a simplified lumped parameter model (LPM) taking into account the voltage at the voice coil terminals and the stiffness of the suspension and speaker membrane surface. The geometry was generated from a manual 3D scan (see Figure 4).

Using a post-processing algorithm implemented in Matlab software and an add-on product to Comsol Harman called LiveLink for Matlab, which creates a bidirectional link between the two programmes, the team converted the point cloud created by the scan into a surface mesh of the car cabin (see Figure 1) and created an optimised mesh for studying acoustic pressure waves.

The simulation analysed the interaction of the sound waves generated by a speaker with the different materials of the windshield, floor, seats, headrests, steering wheel and other sections (such as the roof, doors and instrument panels), each of which have different absorption properties.

In addition to accounting for many different materials, the team also defined speaker membrane motion and acceleration, based on the volume of the enclosure using the Livelink for Matlab and developed special Matlab scripts in order to simplify the preprocessing and postprocessing activities.

“Everything is fully optimised and automatic, so that we do not have to calculate the acceleration for each case; when one simulation finishes, the next launches,” explains Michal Bogdanski. “This ensures that the whole process is easy and error-free; we simply let the scripts run.”

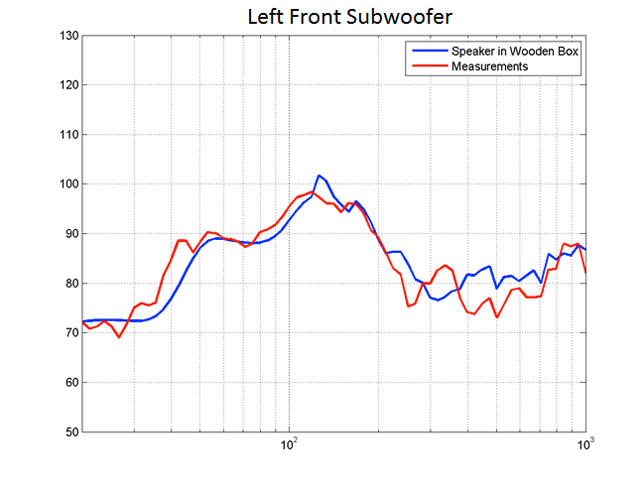

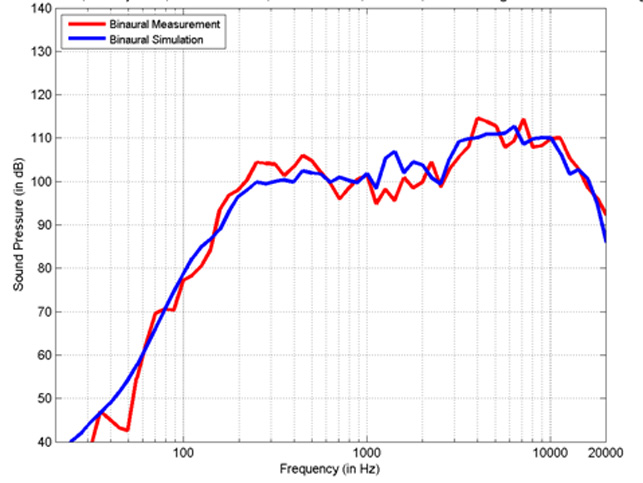

The team also optimised the frequency-dependent absorption coefficients necessary to achieve a strong correlation between the measured and simulated sound pressures. The analysis then provided the sound pressure levels emanating from each microphone array (see Figure 5 and 7).

FIG. 5

FIG. 6 Sound pressure levels for one microphone array…and throughout the cabin

In the driver’s seat

These validated simulations are what enable the team at Harman to begin developing a sound system even as the vehicle itself is still being designed. The accurate prediction of the sound pressure field throughout the car cabin allows for optimisation of audio system performance.

Equalizers and psychoacoustic effects are also included in the tuning algorithm, allowing for design modifications without the need for a physical prototype.

Auralistion, or the production of sound from virtually computed acoustics, is of interest in the pursuit of a top-notch sound system. Using a high-end headphone, engineers at Harman have developed a playback system that allows for listening, evaluation and comparison of audio systems comprising subwoofers, midranges and tweeters, “all based on simulation results and signal processing,” as Malbos puts it.

They include the effects of the human head, torso and ear canals on acoustics in predicting Binaural Impulse Responses (BRIRs) – the way in which ears receive a sound.

To capture the full 3D sound, BRIRs are computed at various head positions in the azimuth plane. The playback system uses a head position tracker in order to perfectly reproduce the sound experience as the listener would experience it; for example in the driver’s seat or the front passenger seat. (Figure 7 depicts the mesh created using Comsol software that was used in predicting BRIR and Figure 8 shows a comparison between predicted and simulated BRIR.)

Auralisation is not without its challenges, since auralisation quality, an inherently subjective measure, must compare to real-world listening.

At Harman, the ability to assess an audio system based purely on simulation has increased the quality of product and speed of product development.

It also has improved customer responsiveness and lowered the cost of design amendments, fostering a sense of design freedom among the company’s engineers.

“The beauty of simulation is that a systems engineer can sit at a desk, put headphones on and begin to tune a system without the car,” says Strauss.

“Using simulation, Harman engineers will be able to assess, optimise, predict and subjectively evaluate the performance of a proposed sound system, even though it does not actually exist yet.”

FIG. 7 Mesh created using Comsol used for the prediction of binaural impulse responses, or how ears receive a sound

FIG. 8 Comparison of measured and simulated BRIR in the frequency domain