Iceotope brings ‘total liquid cooling’ to the desktop by submerging every component inside its custom-built workstation in a non-conductive coolant, making it ideal for harsh and dusty workplaces

Open up your average desktop workstation and you’ll almost certainly find a blanket of dust covering key components, heatsinks and fans.

This can have a huge impact on thermal management inside your machine. Fans need to work harder to achieve the same level of cooling and this means more noise. In some cases, processors can even be throttled, meaning renders take longer or 3D models jump about on the screen.

For most workstations, this is nothing that a good spring clean and a can of compressed air won’t fix, but in harsh environments – think manufacturing shop floors or construction sites – machines can get clogged up very quickly and even fail. It’s not unheard-of on building refurbishment projects for on-site workstations to need replacing every six months.

While some traditional workstation manufacturers tackle this problem with replaceable dust filters, Sheffield-based Iceotope has made dust ingress a non-issue.

The company’s new EdgeStation workstations are completely sealed so there’s simply no way for dust to get in.

Iceotope makes this possible with an innovative system that uses liquid, instead of air, to cool all of the components inside.

This isn’t the ‘direct to chip’ liquid cooling used by some specialist workstation manufacturers, where a closed-loop system moves heat away from the CPU. Instead, Iceotope promises ‘total liquid cooling’, where every single component, from the CPU and memory to the motherboard and Power Supply Unit (PSU), is completely immersed in a dielectric fluid. This is nothing like water – you could submerge a mobile phone in this non-conductive coolant and still make a call.

The entire machine is passively cooled, with liquid circulating throughout the machine thanks to natural convection.

There are no fans at all, making it completely silent in operation. During manufacture , Iceotope even disables or removes the fans that are built into the GPU or PSU.

The chassis is made up of two substantial hunks of metal that act as heatsinks, each with several fins that have been optimised for heat transfer using Computational Fluid Dynamics (CFD) software.

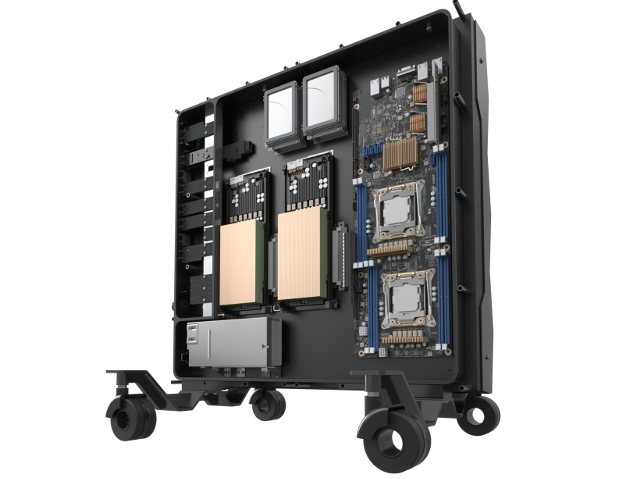

All of the IT is connected to one side of the chassis, then the two halves are clamped together, sealed and filled with coolant. This makes for a very heavy machine, with a typical system weighing in around 70kg to 75kg, around three times the weight of a traditional high-end workstation. However, the machine comes on wheels, so once inside the building, it is relatively movable.

A huge amount of engineering has gone into the development of the system and the internal vessel that holds the liquid is much more slender than the inside of a traditional workstation. CPUs are fitted with server-grade heatsinks and memory modules are arranged vertically to ensure the coolant flows smoothly over the surface, as it rises with heat.

GPUs and SSDs are mounted adjacent to the motherboard and connected via high-spec cables. If the GPUs were connected in the traditional way, at right angles to the motherboard, says Iceotope, this would require a massive pressure vessel – and a lot more coolant, which is very expensive.

As each GPU is completely submerged, so are the DisplayPort outputs. This means the signal needs to be routed to the exterior of the machine, and here, a high-quality cable and a custom board are used to boost the signal. Similar patented ‘Liquid to Air’ (L2A) I/O connector technology is used for USB, Ethernet and other I/O.

Iceotope – workstation-class

While the chassis and electronics are all custom built, the core workstation components are standard fare. Iceotope offers a range of different machines, all fully customisable, from a single socket Intel Xeon E3-1200 CPU for CAD work to a dual socket Intel Xeon E5-2600 CPU for rendering or simulation.

Other options include one or two Nvidia Quadro or AMD Radeon Pro GPUs, up to four 2.5-inch Solid State Drives (SSDs) as well as NVMe SSDs.

Hard Disc Drives (HDDs) are not currently supported, but Iceotope says this is on its product development roadmap within the next six months.

While some workstation manufacturers use liquid cooling to boost performance, this is not the intention for Iceotope’s system. CPUs and GPUs run at standard clock speeds, although Iceotope says that its machines never slow down due to throttling, which has been known to happen in air-cooled systems under heavy loads in warmer months.

Closed for business

One of the big trade-offs in having a completely sealed system is limited serviceability.

Mainstream workstations from HP, Dell, Lenovo and Fujitsu feature tool-less chassis, making it very easy for customers to replace components should they fail. If the Iceotope EdgeStation breaks down, it has to be returned to base to be fixed, although a replacement system will be sent to avoid downtime.

Of course, with no moving parts at all, a breakdown is much less likely – even less so when compared to an air-cooled machine in a harsh environment.

However, SSDs are still prone to failure, regardless of how they are cooled, so we’d recommend an SSD with a high endurance rating, such as a Samsung SSD Pro, and maybe doubling up with mirrored drives in RAID 0.

Then, if one drive fails, the system keeps working and the repair can be done when convenient and not when you are on a critical deadline.

As most SSDs can be passively cooled, it would make a lot of sense to put them on the outside of the machine so they are easily accessible. How easy this would be to engineer, of course, is another matter.

Conclusion

Iceotope’s EdgeStation is a specialist piece of kit that looks to solve the specific challenge of operating a workstation in a harsh environment, where standard aircooled machines run the risk of slowing down or failing.

This is usually in places where there are airborne particles – be they dust, fibres or even bits of metal – but could also mean environments characterised by extreme heat.

The construction site is one obvious example, but there could also be a place for the EdgeStation in industrial environments where workstations need to be close to equipment such as CNC machines, industrial 3D printers, laser scanners or coordinate measuring machines (CMMs).

The Advanced Manufacturing Research Centre (AMRC) at the University of Sheffield, for example, uses an EdgeStation to solve the problem of dust particles in its carbon fibre laboratories.

From what we have seen in the Iceotope workshop in Sheffield, the engineering behind the EdgeStation is impressive. Each machine is custom built by hand.

In theory, with no moving parts, reliability should be excellent (air-cooled workstations have multiple fans, so multiple points of failure). However, it’s a shame that the SSDs are not accessible, to allow users to perform some simple maintenance tasks themselves.

Surprisingly, the standard warranty is one year (almost all workstations come with three years), but extended warranties are available on request.

As one would expect, because of the complex engineering involved, EdgeStations come at a significant premium.

A standard CAD workstation – with an Intel Xeon E3-1240 v6, Nvidia Quadro P2000, 32GB RAM and 512GB M.2 NVMe SSD, for example – will set you back £4,925. A typical workstation for design viz – with dual Intel Xeon E5-2667 v4, Nvidia Quadro P5000, 64GB RAM and 512GB M.2 NVMe SSD – comes in at £10,244.

But if you need a machine to stand up to everything a building site or workshop can throw at it, then this could certainly be a price worth paying.

Iceotope – renderfarm / HPC cluster without the noise

Iceotope doesn’t just make workstations. The company is actually best known for its data centre blade server solutions, which are based on a more advanced implementation of its liquid cooling technology.

The beauty of Iceotope’s server solution is that it doesn’t need a dedicated airconditioned data centre. There are no noisy fans; instead, it uses a three-stage cooling process that takes the heat from the blades, moves it into the rack and then away to an air blast box housed outside the building.

Alternatively, hot water produced at the third stage can be re-used, by plumbing it into radiators to heat other parts of the building.

The AMRC in Sheffield, for example, is planning to use this method to heat the factory floor.

Iceotope says it has also seen interest from production studios in Soho, London, which may not have the space or permission to build a dedicated data centre room, or simply don’t want the noise pollution from hundreds of fans running flat-out. In theory, Iceotope’s 24U cabinets, which each have the capacity for nine blades, could happily sit in the corner of an office, next to the workstations.

The liquid cooled blades can be fully customised with a choice of Intel Xeon E5-2600 CPUs, low-profile RDIMM memory, SSD and optional InfiniBand. There’s also a liquid-cooled GPU server that occupies a dual blade slot, a liquid-cooled switch and a liquid- cooled power supply, so the entire system can be optimised for minimum noise.