Audi, with a little coaxing from Stratasys, has revealed how 3D printing parts has sped up its new vehicle approval process from a design standpoint – and it’s not necessarily the parts you’d expect either.

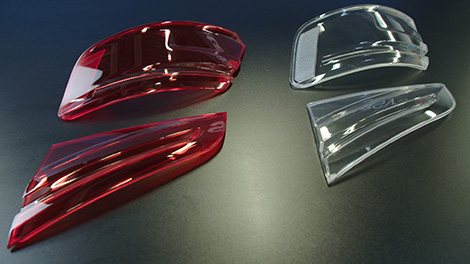

The Audi Pre-Series Center in Ingolstadt has built rear light covers using its Stratasys’ J750 full-color, multi-material 3D printer, nailing the colour accuracy and textures, along with the all important transparency allowed by the ‘digital materials’ process.

Physical models and prototypes for the brand require the allocation of most parts of the vehicle in an early stage of product development – everything from wheel covers and door handles to radiator grills – for which the team traditionally uses milling or molding to produce components.

In the case of the rear light fittings, this included several parts that needed careful assembly.

With over 500,000 color combinations available on the J750, the team now 3D prints a single transparent part in multiple colors and textures to meet the stringent Audi design approval process.

“Design is one of the most important buying decisions for Audi customers, therefore it’s crucial we adhere to supreme quality standards during the design and concept phase of vehicle development,” explains Dr. Tim Spiering, who as head of a 24-member team is responsible for providing all plastics 3D printing expertise, advice and production at Audi.

“As a result, we need prototypes to have exact part geometries, no distortion and extremely high quality, as well as true-to-part color and transparency. The Stratasys J750 3D Printer will offer us a significant advantage, as it allows us to print the exact textures and colors our design defines. This is essential for getting design concepts approved for production.

Spiering estimates time-savings of up to 50 per cent from using this 3D printing technique in the prototyping process of the light covers, as it looks to add further time savings across the entire design verification process.

With over 16 years of 3D printing experience, the division has grown its portfolio to ten polymer 3D printers, including a range of Stratasys FDM and PolyJet 3D Printers.

Stratasys EMEA president Andy Middleton, concluded: “If you extend the time-savings achieved by Audi on the tail lights to other parts of the vehicle, the overall impact on time-to-market can be huge.

“We’re excited to see how Audi continues to leverage our FDM and PolyJet technologies into new application areas to further increase efficiencies across its development process.”